You’re in good company!

Goodbye manual processes,

communication gaps, and inefficiencies

Hello streamlined workflows!

Workerbase is the only platform that connects workers, machines and

IT systems to turn data into flexible manufacturing execution

Discover our connected worker use cases

Popular connected worker features

Guide and train staff: work instructions

Enable your workforce with step-by-step guides. Ensure consistency, reduce the risk of errors and let your team work even more efficiently.

Ensure accuracy and compliance: digital checklists

Walk teams through processes with customizable checklists. Keep track of critical steps and reduce mistakes. Improve first pass yield and maintain industry standards effortlessly.

Enhance team cooperation: real-time collaboration tools

Share insights, resolve issues, and accomplish more together with real-time collaboration tools. Troubleshoot together and establish best practices to increase productivity.

Drive operational excellence: continuous improvement

Collect improvement proposals. Analyze data holistically. Uncover actionable insights that drive lean practices and quickly implement changes.

Process automation. It’s time to take connected worker to the next level

Optimize and automate factory processes based on real-time data

Group coordination

Workerbase automatically assigns tasks based on workload distribution and skill levels to find the perfect person for the job. Notifying supervisors, sending alerts to maintenance teams, and rerouting tasks has never been easier.

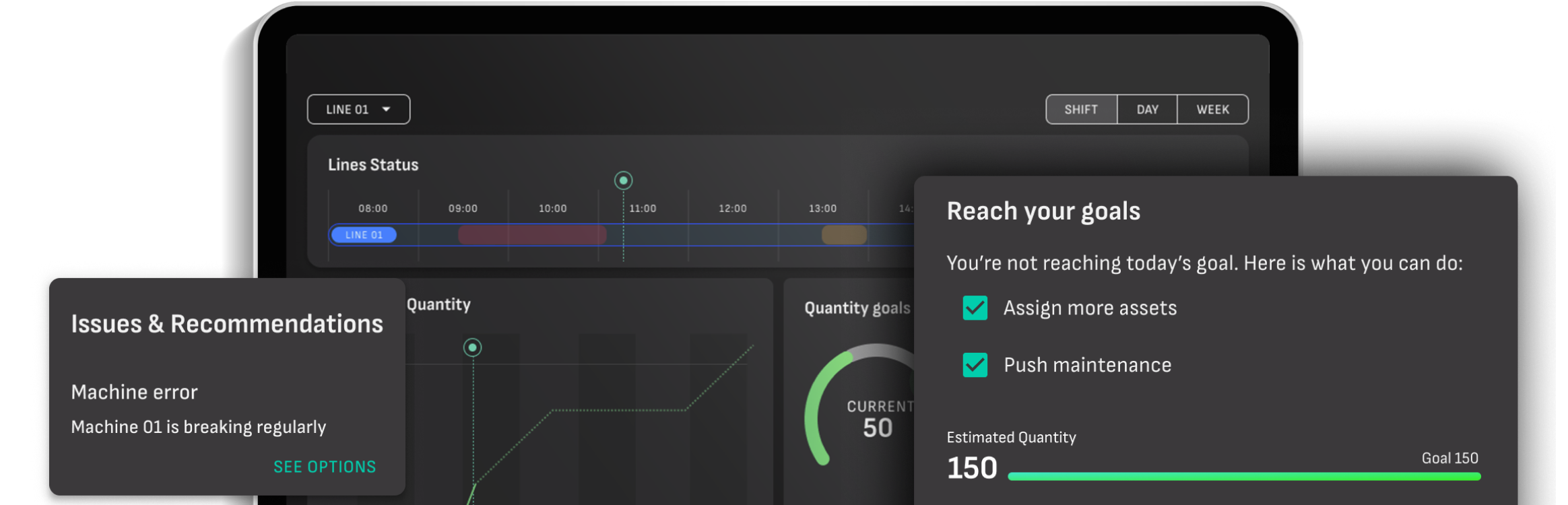

AI-driven process adaptation

Workerbase automatically analyzes real-time data to anticipate disruptions and adapt workflows. Our advanced AI technology creates self-optimizing processes that keep you ahead of the curve.

Prioritization

Workerbase automatically prioritizes tasks based on resource availability and production goals. Critical tasks receive attention when needed. Priorities are adjusted in real-time to meet changing demand.

Work orchestration

Workerbase automatically orchestrates tasks and processes based on real-time data. Workflows are triggered without manual intervention as soon as the previous phase is complete

Transform your operations in weeks. Not years.

Workerbase core platform features at a glance

Low code app builder

Shortage of IT resources slowing down your digital transformation? Design custom workflows in minutes.

Data connectors

Bye-bye, siloed IT architecture! Connect all your data sources to one platform to gain visibility and close execution gaps.

Data analytics

Keep a real-time view of your operations. With live KPIs and dashboards, every decision is data-driven.

Governance and compliance

Enterprise-grade governance and compliance tools for user management, version control and monitoring.