Transforming Manufacturing Together

Here’s Why Leading Manufacturers Use Workerbase.

Everything You Need, in One Place

Workerbase connects all your systems & data onto one digital platform.

- Connect all your systems with over 100 platform integrations supported.

- Overhaul your paper processes and documentation onto a central platform.

- One unified interface to simplify and improve end-user experience.

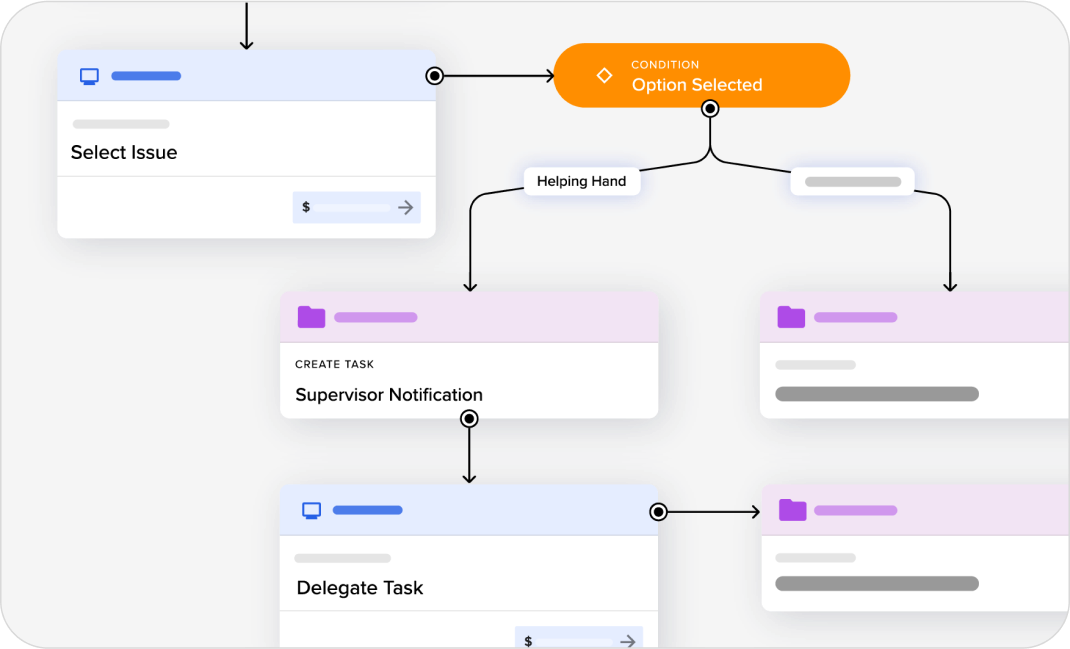

Digitize and Automate Your Operations

Low-code platform to recreate your operations as automated digital workflows.

- Eliminate unnecessary interfacing for information and decision making.

- Configure unlimited workflows for your production environment.

- Access over 25 pre-built apps within 6 preconfigured solution packages.

Connect Workers With Data and AI

Boost productivity with real time data and AI copilot on personal smart devices.

- Provide workers with instant access to task relevant information.

- Document and share best practices to foster knowledge transfer.

- Connect front line workers with smart watches built for industrial use.

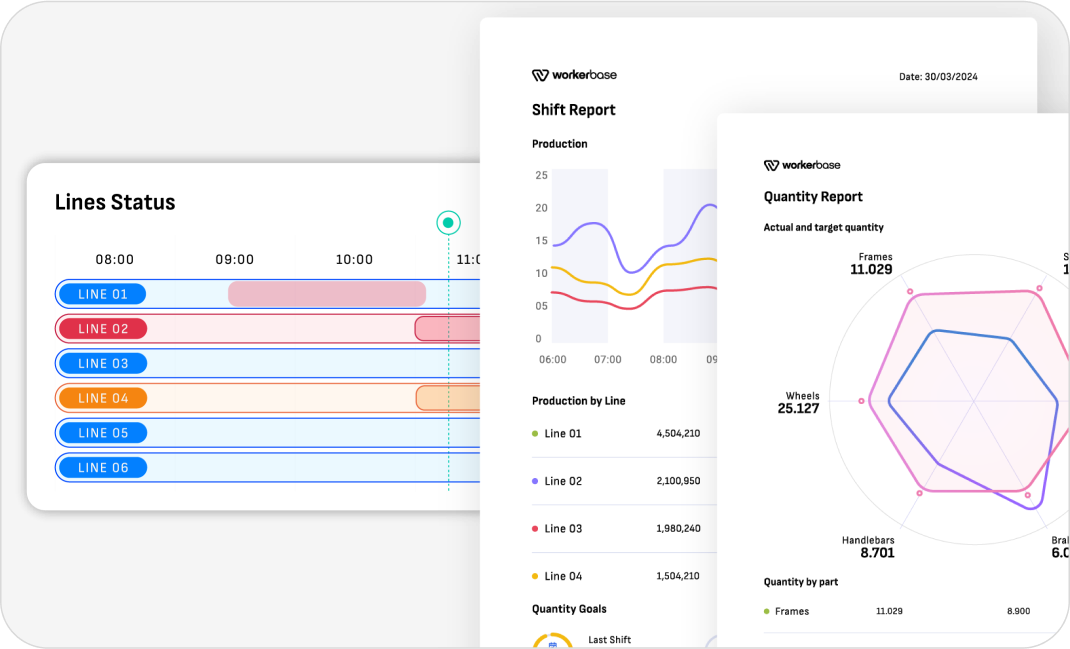

Create and Realize Business Value

Unlock business potential with streamlined operations, comprehensive analytics and accelerated time-to-value.

- Gain real-time insights into production processes and equipment status.

- Leverage analytics to identify gaps and implement improvements.

- Enhance business value by improving key KPIs including throughput, OEE, downtime, rework, scrap, and worker productivity.

Discover Workerbase’s different solution modules built

for your manufacturing needs.

Digital ANDON

Enable smooth operations by providing digital support requests.

Machine Operations

Optimize machine operation and minimize downtime.

Assembly

Equip your employees with step-by-step assembly instructions.

Quality

Enhance quality with seamless tracking and defect reporting.

Intralogistics

Allow for digital inventory management and coordination.