Why connect frontline workers?

It takes just days to get your first production lines running with Workerbase

Analog Worker

-

Face-to-face, paper-based communication

-

Information on paper and blackboards

-

Paper tasks, verbal assignment

-

In-person training and knowledge sharing

-

Manual maintenance scheduling

-

Manual quality inspections

-

Periodic manual reporting

Connected Worker

-

Instant, digital communication

-

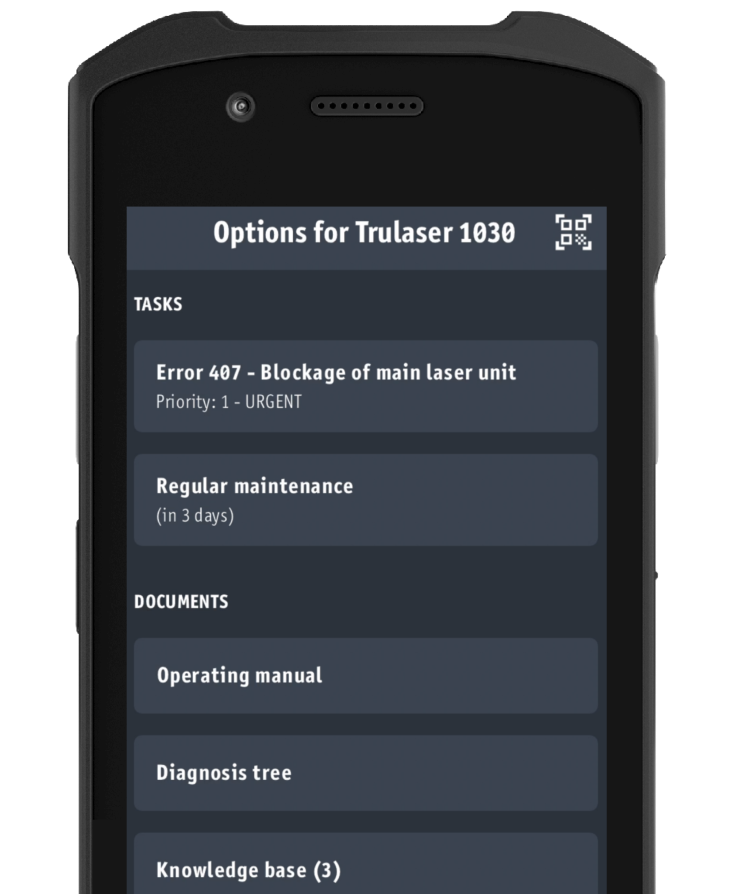

Real-time, digital access to information

-

Digital tasks, real-time progress tracking

-

Digital training paths, on-the-job guidance

-

Real-time monitoring, alerts and reporting

-

Predictive, IoT-enabled maintenance

-

Real-time, customizable dashboards

How does Workerbase work?

Our most popular use cases – with reason. Here are some of the ways you can get started with Workerbase and immediately start seeing value.Here’s what you get with Workerbase

Digital work instructions

Digital Andon

Shift handover

Issue reporting

Customizable real-time dashboards

Digital checklists

Customizable, auditable reports

Document versioning and publishing

Best practice and knowledge sharing

Bill of materials

Digital access to work orders

Task scheduling

Work order management

Changeover instructions

Why Workerbase?

Discover all the reasons Workerbase could be the perfect fit for your factory

Infinitely scalable

Start with your most pressing use case today, roll it out in a matter of weeks. Scale as quickly as you need without the need for a complex, top-down IT project

Flexible workflow execution

We’re the only Connected Worker platform flexible enough to adapt completely to your processes, your data structure, and your production infrastructure

Out-of-the-box solution

We are a fully customizable, mobile-enabled Connected Worker platform with a powerful suite of ready-to-use apps

Universally compatible

Workerbase integrates seamlessly into your existing infrastructure to act as an intuitive interface for your machine data, ERP, MES and more

Trusted by the world’s largest manufacturing companies