Proactively address issues. Optimize equipment performance. Ensure uninterrupted production.

Efficient maintenance procedures with Connected Worker apps

Minimize downtimes and shorten mean-time-to-repair

Our Connected Worker apps are flexible enough to suit your specific quality needs and work harmoniously together in a one-stop-shop solution. Whether you start with a single app for one assembly work station or configure multiple workflows for all assembly lines, we get you up and running swiftly so you can immediately benefit from digital assembly workflows.

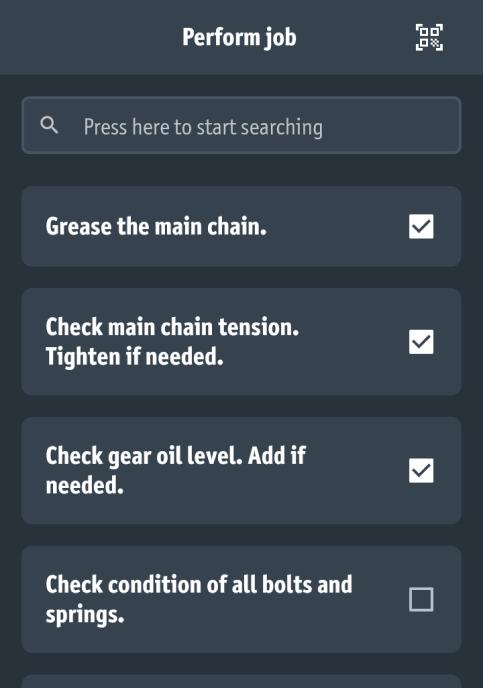

Maintenance Instructions

Ensure consistent and accurate equipment maintenance through step-by-step instructions.

Training

Enable new operators to onboard fast and seasoned operations to adapt quickly. Make complex assembly processes easy to ensure consistent output.

Predictive Maintenance

Leverage data-driven insights to predict equipment failures and schedule maintenance proactively.

Condition Monitoring

Monitor equipment health in real-time, promptly identifying potential issues before they escalate.

Best Practices

Create, share and implement best practices to ensure consistent and efficient equipment maintenance.

Quick Fix Resolution

Empower technicians with quick fix instructions, ensuring rapid response and minimizing downtime.

Service Reports

Generate detailed service reports in real-time, ensuring thorough documentation of maintenance activities.

Issue Documentation

Document maintenance issues for future reference and analysis, facilitating continuous improvement.

Root Cause Analysis

Analyze issue patterns to identify root causes and implement strategic solutions for long-term prevention.

What you get from our maintenance apps

Optimized Uptime

Minimize equipment downtime and maximize availability, ensuring uninterrupted production and operational efficiency.

Reduced Maintenance Costs

Proactive maintenance and data-driven insights lead to reduced repair and replacement expenses.

Enhanced Equipment Performance

Leverage real-time condition monitoring and predictive maintenance to extend equipment lifespan and boost overall performance.

Streamlined Communication

Instant service reporting and quick fix instructions facilitate efficient communication and issue resolution, minimizing disruptions.

Trusted by the world’s largest manufacturing companies