Machine Alarm

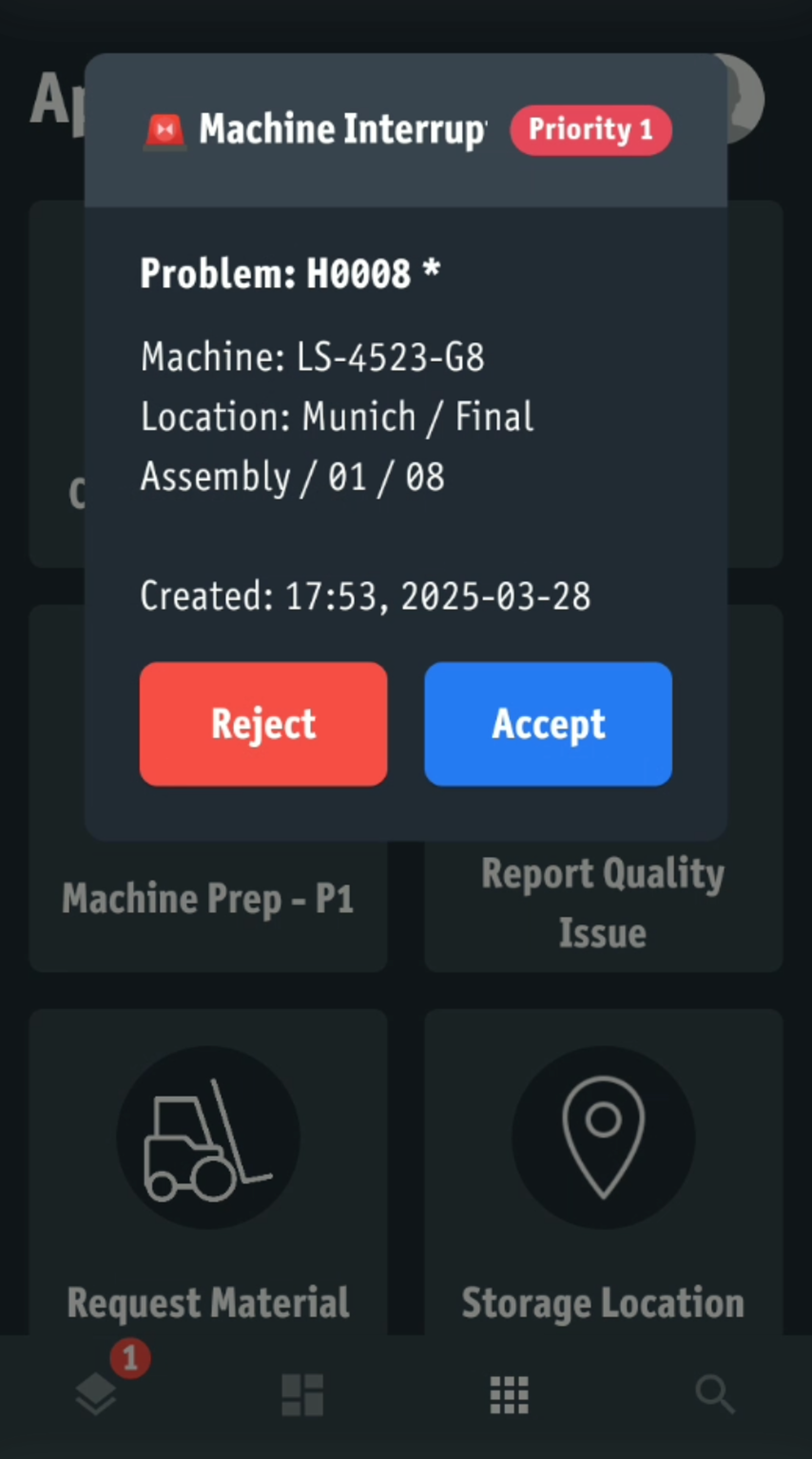

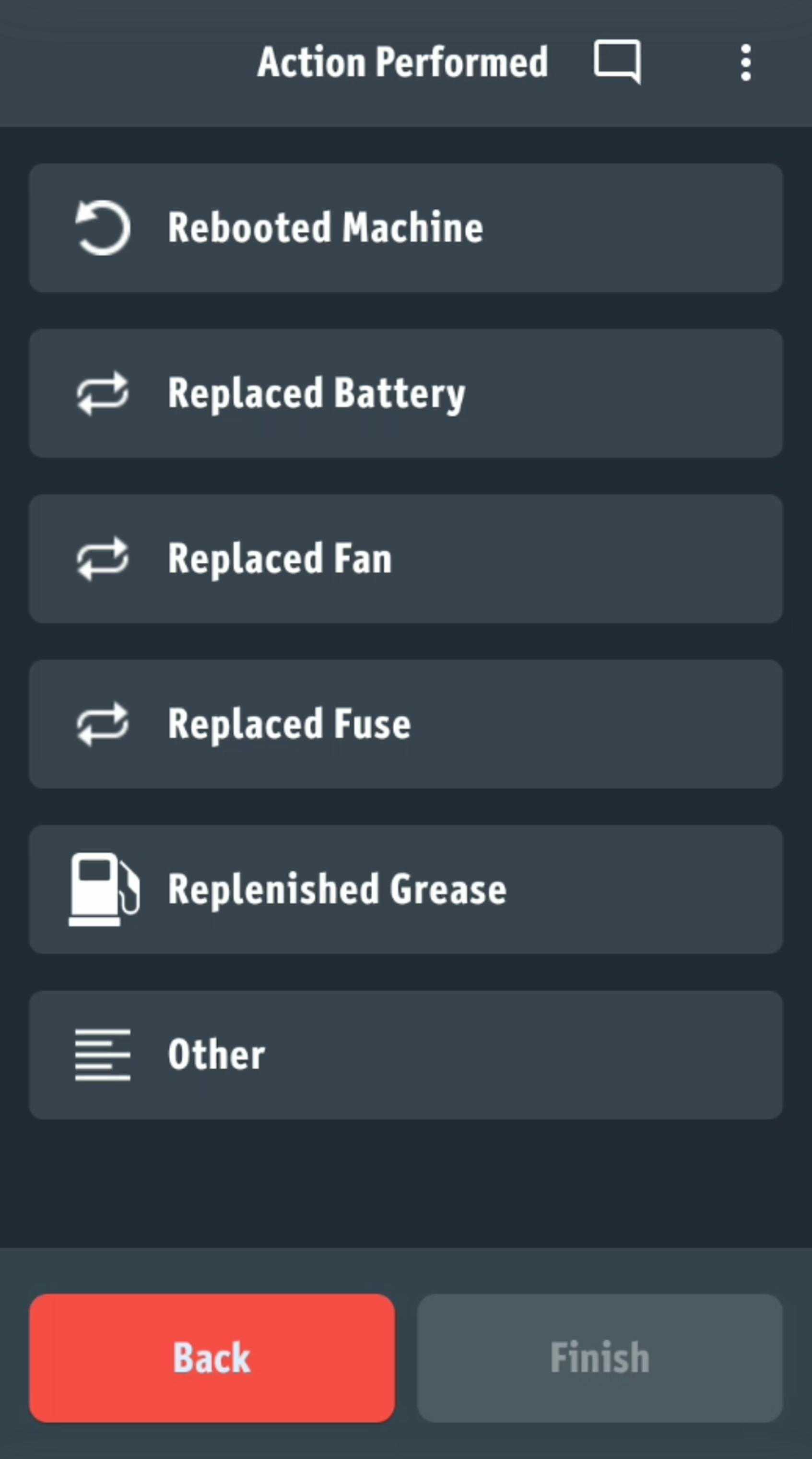

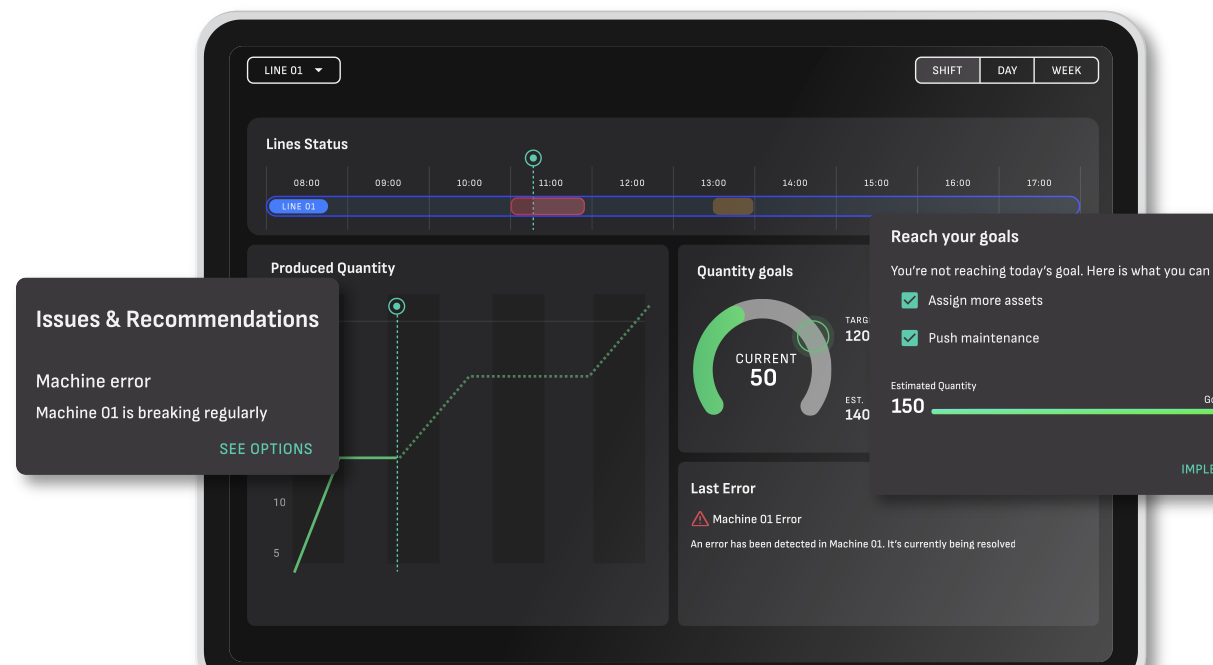

When a machine disruption occurs, mobile alerts are instantly sent to the best-fit operator - based on priority, skill, and their location. Tasks are automatically routed and tracked, and the action taken is logged for future analysis and continuous improvement.

Mobile machine alarms ensure machines are up and running

5% Increased OEE

Improve overall equipment effectiveness by eliminating delays and miscommunication. A 5% OEE boost can translate into entire days of recovered production each month.

Increased Throughput

Produce more without adding extra shifts or machines. With optimized workflows and real-time decisions, you accelerate your line and get more output from the same resources.

20% Faster Reaction Times

Drastically cut the time between issue and response. With instant notifications and automated workflows, your team reacts 20% faster—avoiding downtime and keeping production on track.

Why use the Machine Alarm App?

How our Machine Alarm App streamlines your manufacturing operations

Existing Processes

- Conventional audio or visual signals remain overlooked (e.g. on patrols or go-and-see walks)

- Lack of information regarding errors

- Manual escalation by phone or in person

- Root causes not documented

With Workerbase

- Real time alerts about machine errors sent to mobile devices of operators

- Contextual information immediately available (e.g., alarm history, troubleshooting, error code explanation)

- Automatic escalation via configurable rules

- All information automatically digitally documented (e.g., resolution times, root causes)

Easy steps to implement Machine Alarm

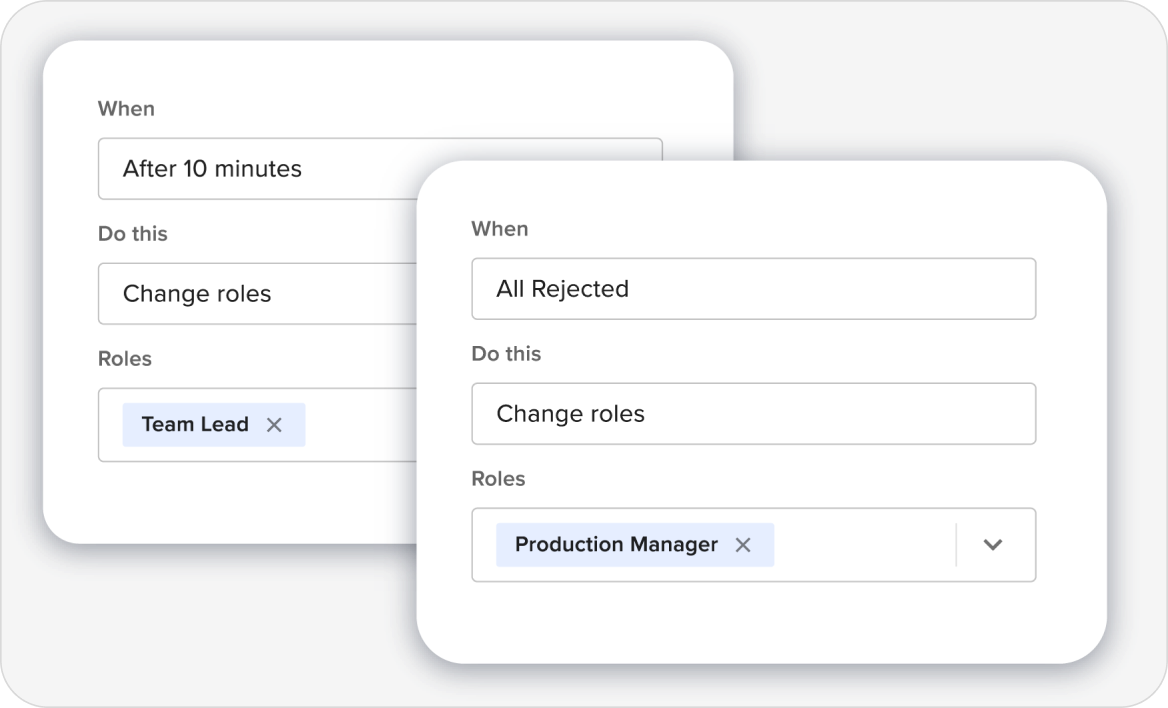

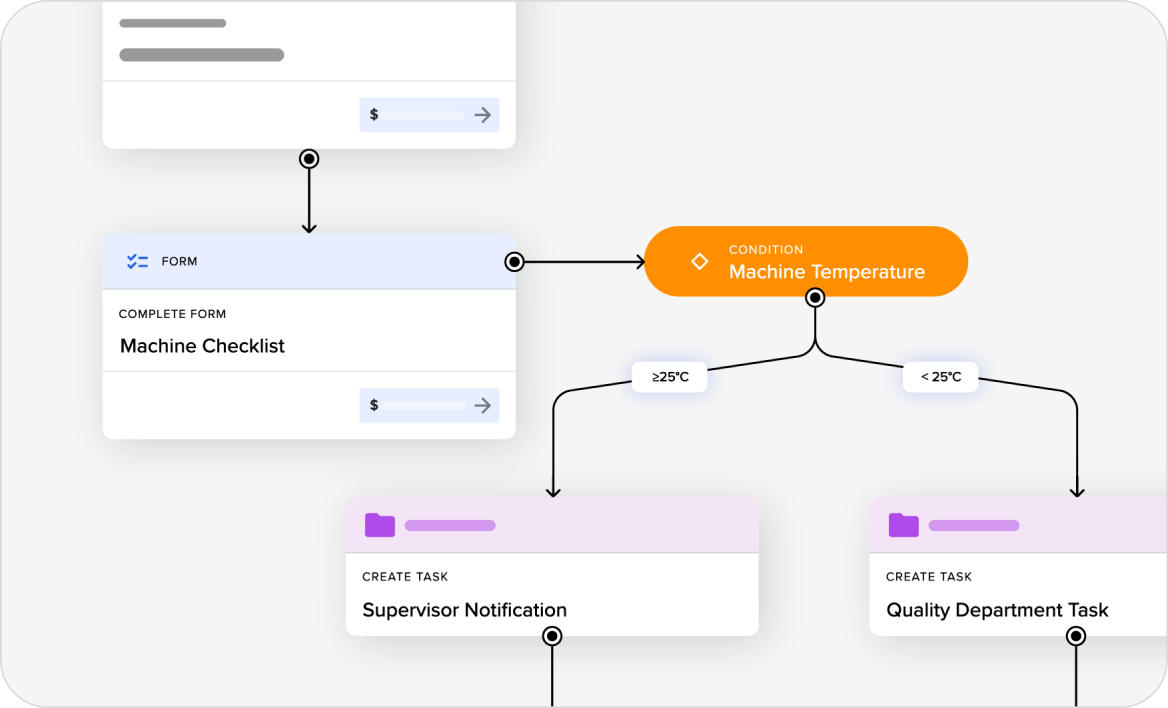

Define your delegation logic

If incidents are not resolved in time or no technicians are available to deal with the breakdown, you can configure how tasks should be escalated or delegated.

Each repair task can be equipped with timeouts and deadlines and the Workerbase task management system will ensure incidents are handled in the given timeframe to minimize any downtime.

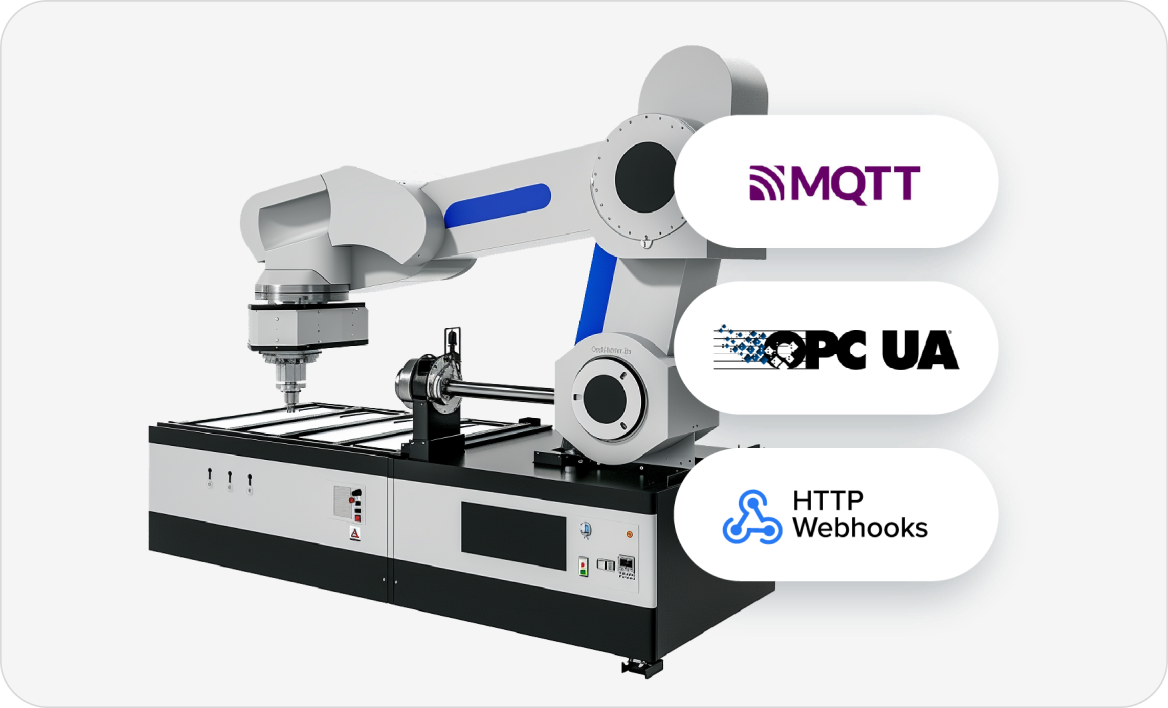

Configure your data points

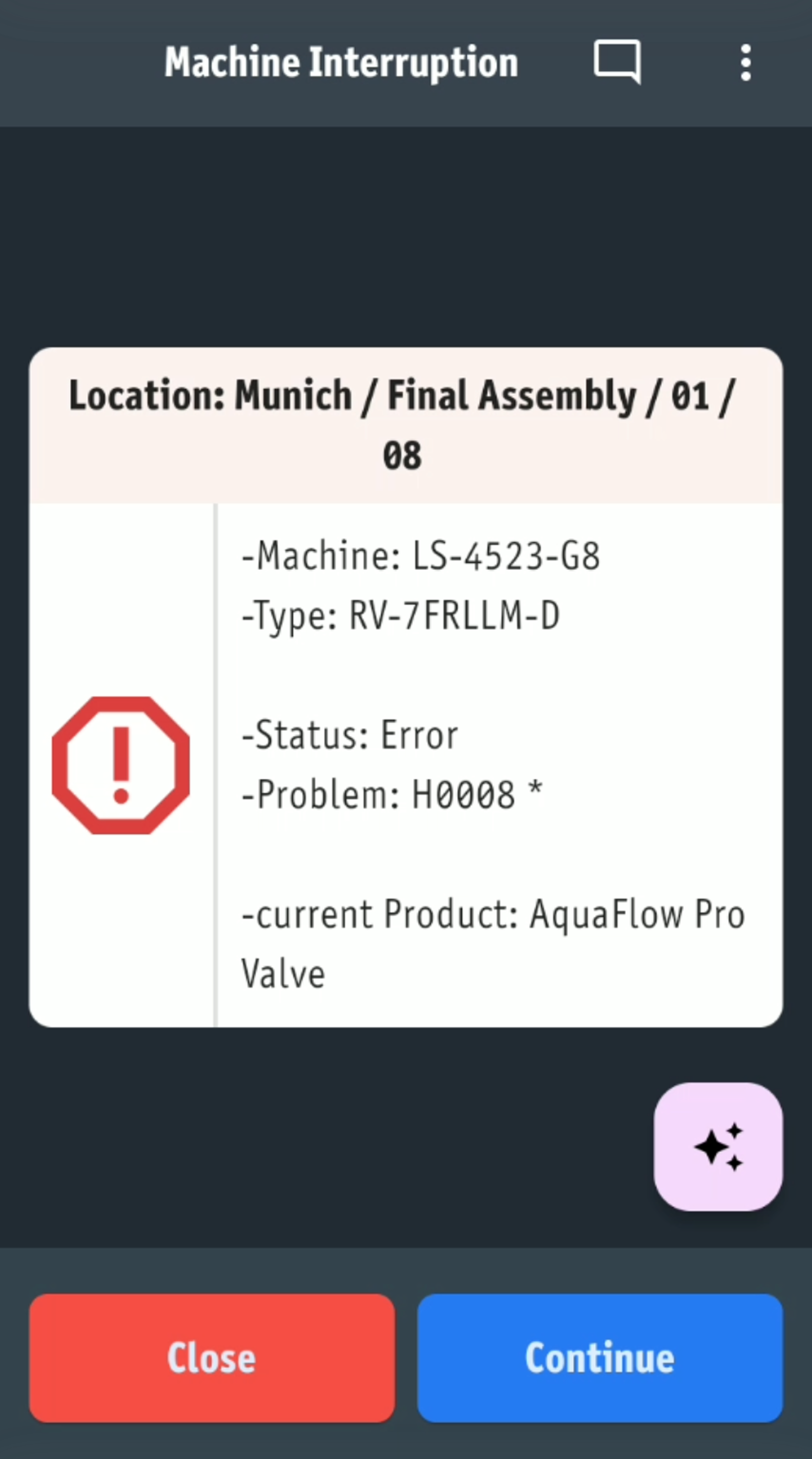

Define the information you want to display in the app. This can be any data point sent from your machine (such as the error code, machine identifier or any sensor data).

Data can be enriched with other contextual information such as the product being run on that particular machine in the moment a breakdown occurs.

Define your notification logic

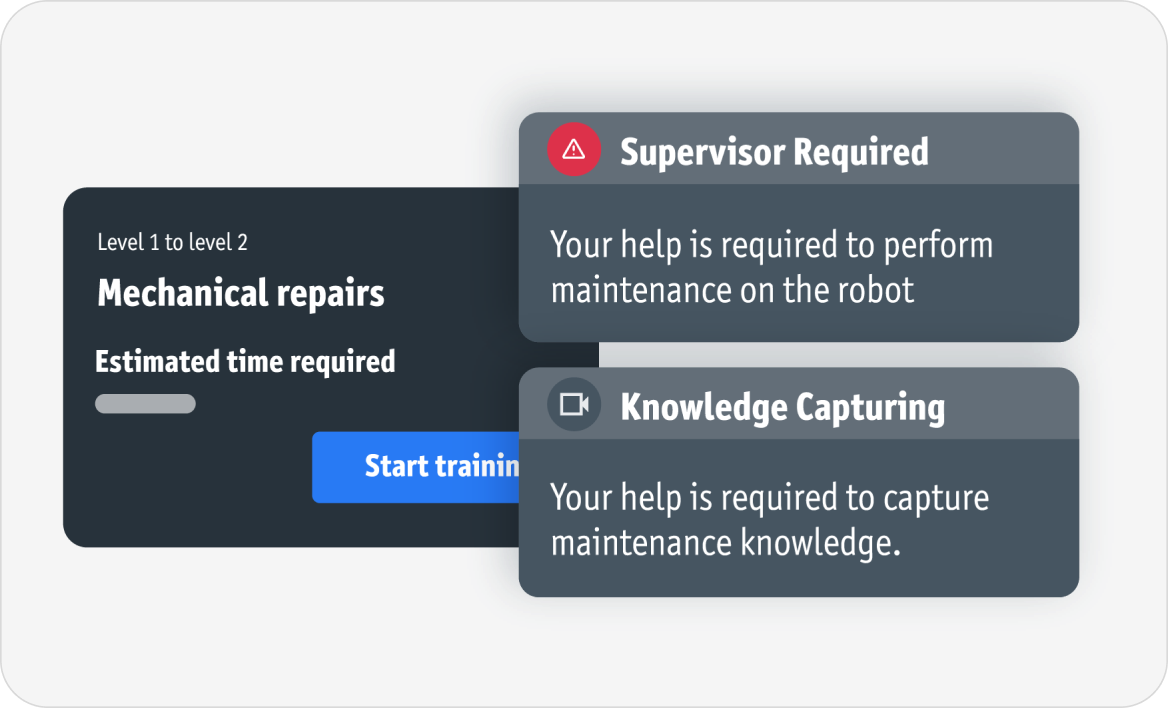

Configure how the machine breakdown alert is sent out to your operators. This can be configured by criteria such as priority, location, and skill level.

Additionally you can include instructions on how to resolve the breakdown and enable our AI Troubleshooting Agent to assist technicians with the repairs.

See 25% Faster Reactions and 5% OEE Gain

Discover Why Industry Leaders Use Workerbase

We’d love to walk you through how our platform can solve your specific manufacturing and production challenges and deliver measurable results.

We’d also be happy to share more insights on how our platform tackles challenges such as:

- Information access and task related support for frontline workers

- Inflexible and siloed IT infrastructure, such as existing MES or ERPs

- Achieving data maturity from your entire manufacturing ecosystem