Machine Changeover

Changing over machines for new products or processes is often time-consuming, error-prone, and heavily dependent on paper-based documentation and a frontline worker's skill level.

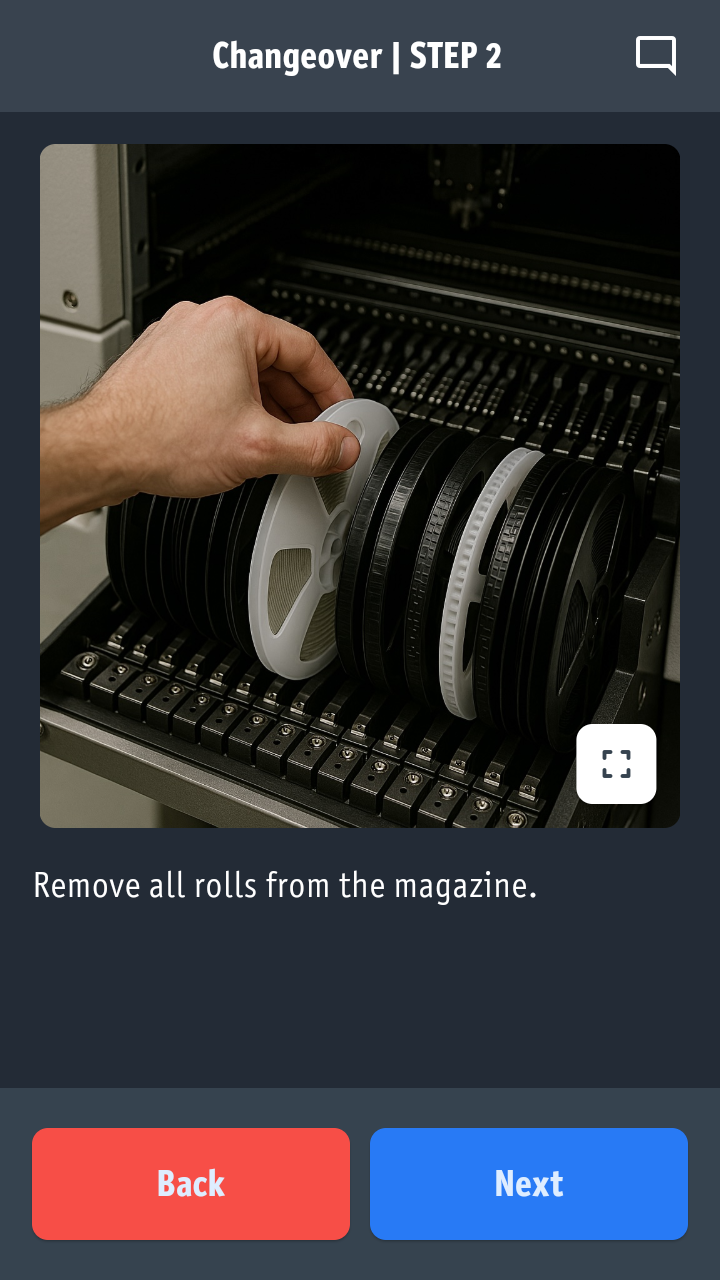

This is where the machine changeover app replaces paper instructions and unstructured tasks with a digital, step-by-step instructions. Changeover tasks are coordinated between all relevant roles to streamline the process.

Significantly streamline your changeover processes

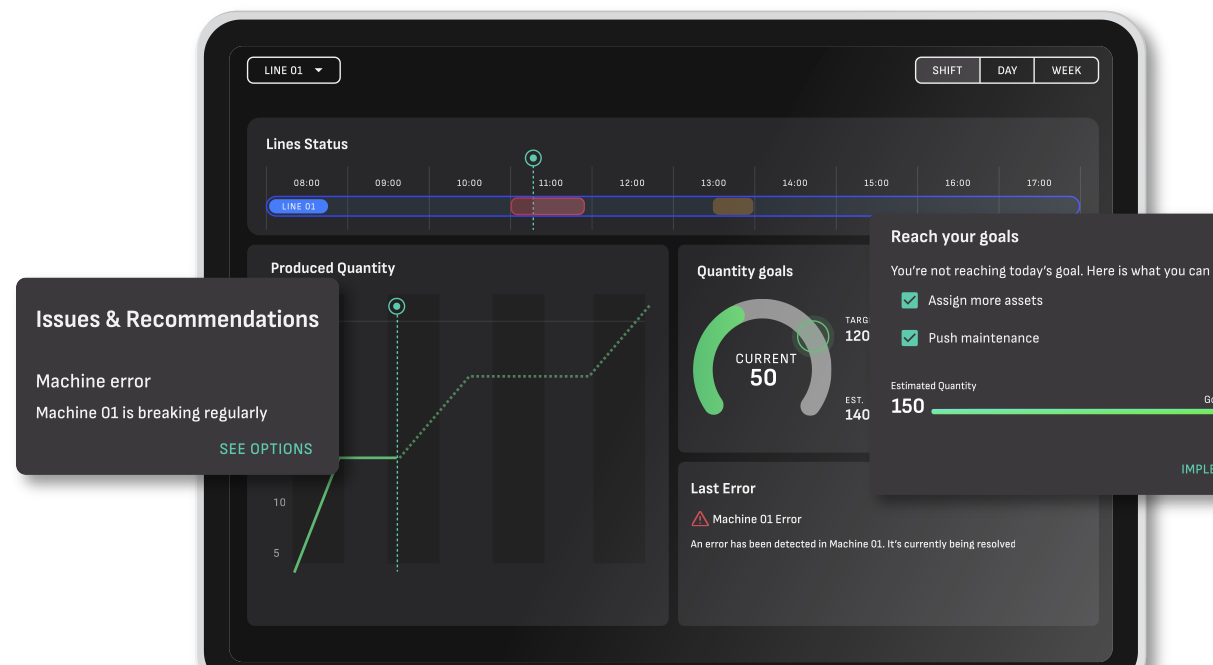

Increase OEE

Minimize changeover downtime and ensure faster restarts—every setup counts toward better overall equipment effectiveness.

Reduce Changeover Time

Standardize and digitize each step of the changeover process—less guesswork, fewer delays, and faster transitions.

Increase Throughput

Speed up product switches without compromising quality—keeping your lines productive across more shifts and variants.

Why use the Machine Changeover App?

How our Machine Changeover App streamlines your manufacturing operations

Existing Processes

- Scattered change over instructions or paper-based manuals that are tough to track

- Manual coordination of tasks and unclear responsibilities

- Few workers possessing the skills required

With Workerbase

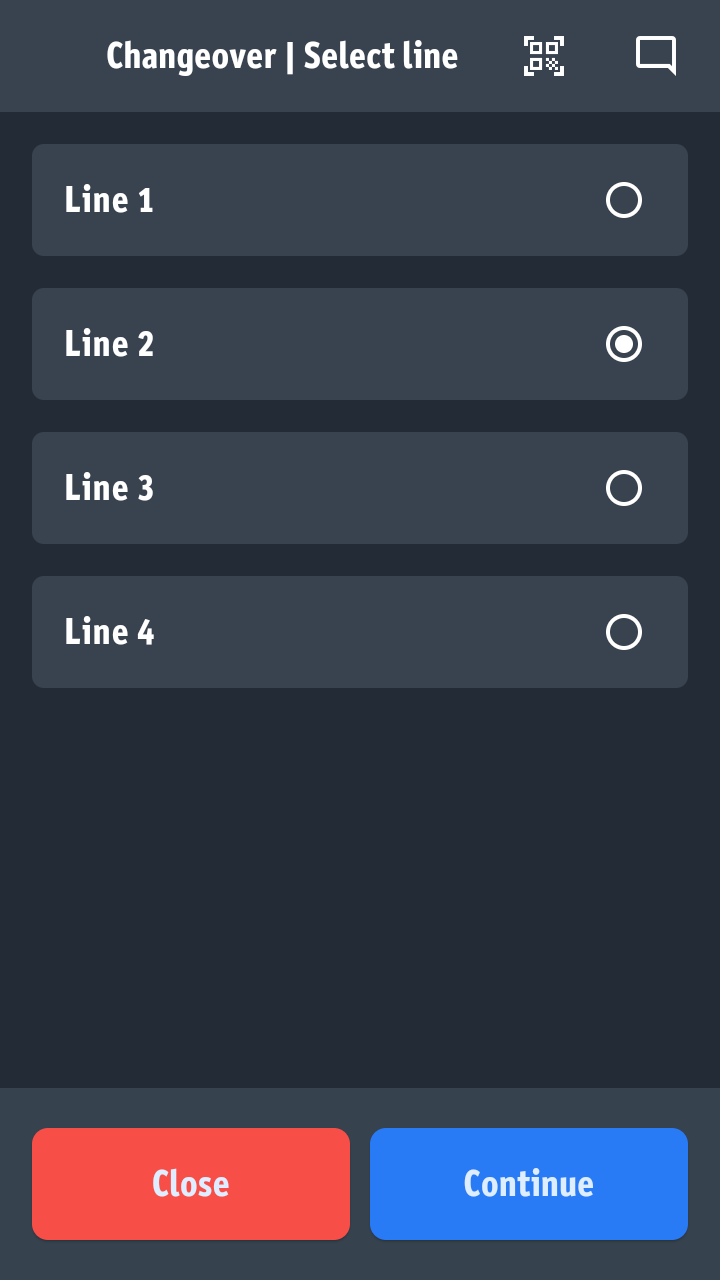

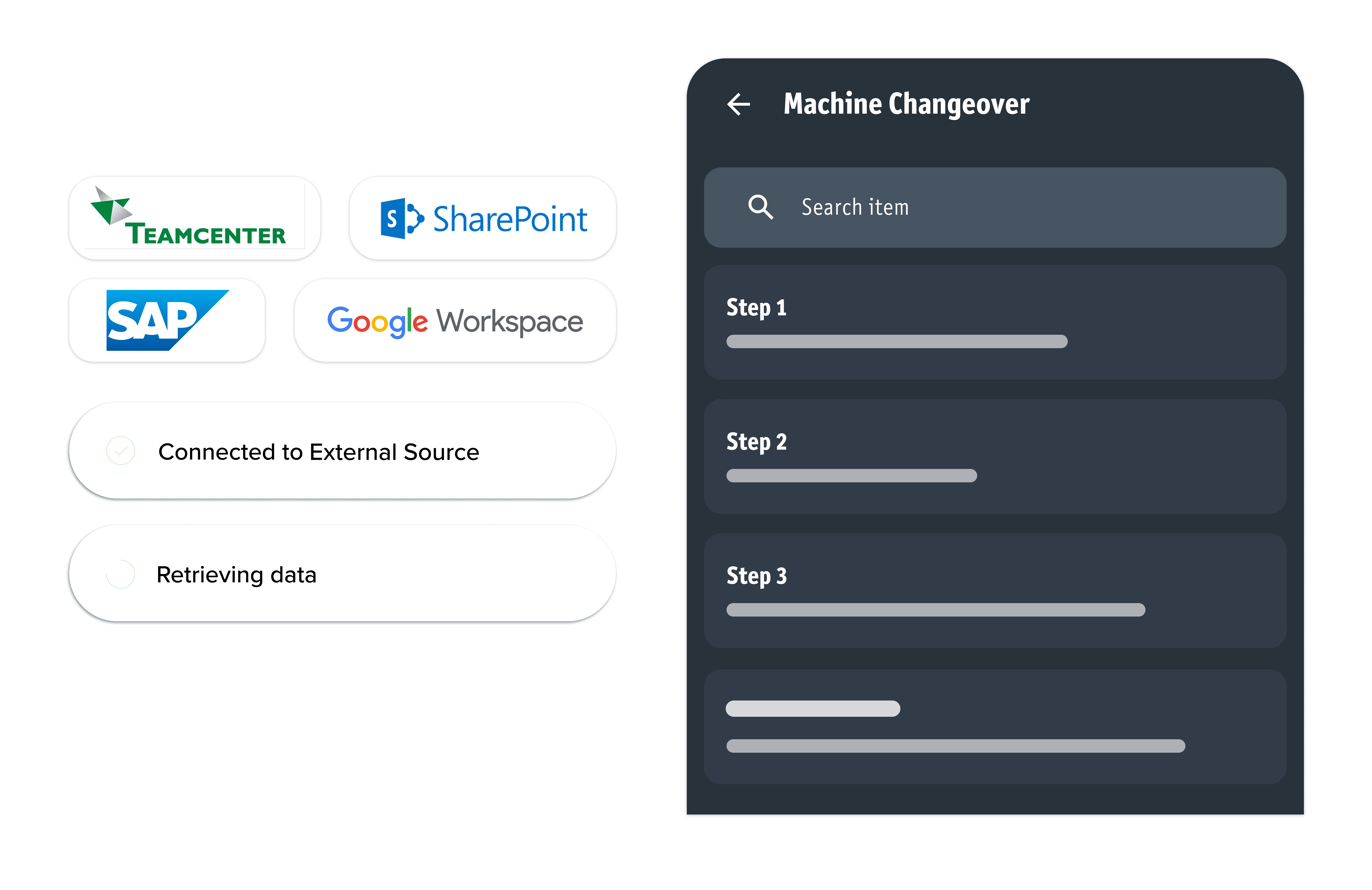

- Digital, standardized work instructions and checklists accessible anytime

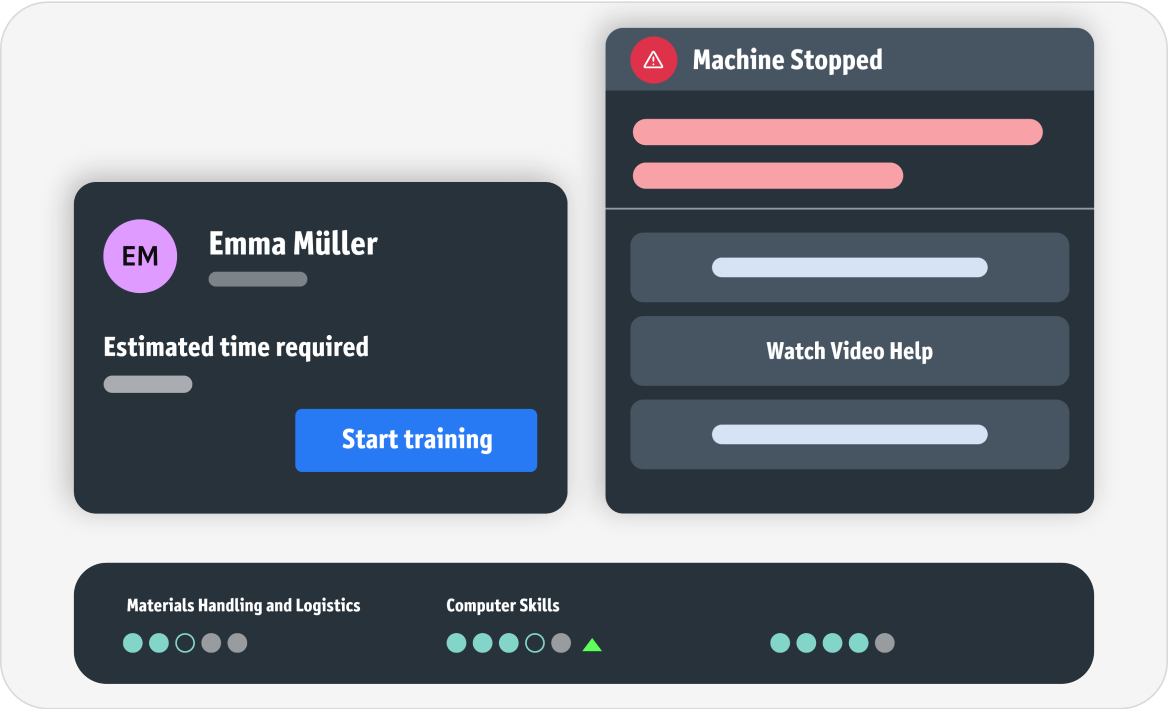

- Automated task assignments and alerts for the right person based on skills and availability

- Digital knowledge capture to transfer essential knowledge between workers

Easy steps to implement machine alarms

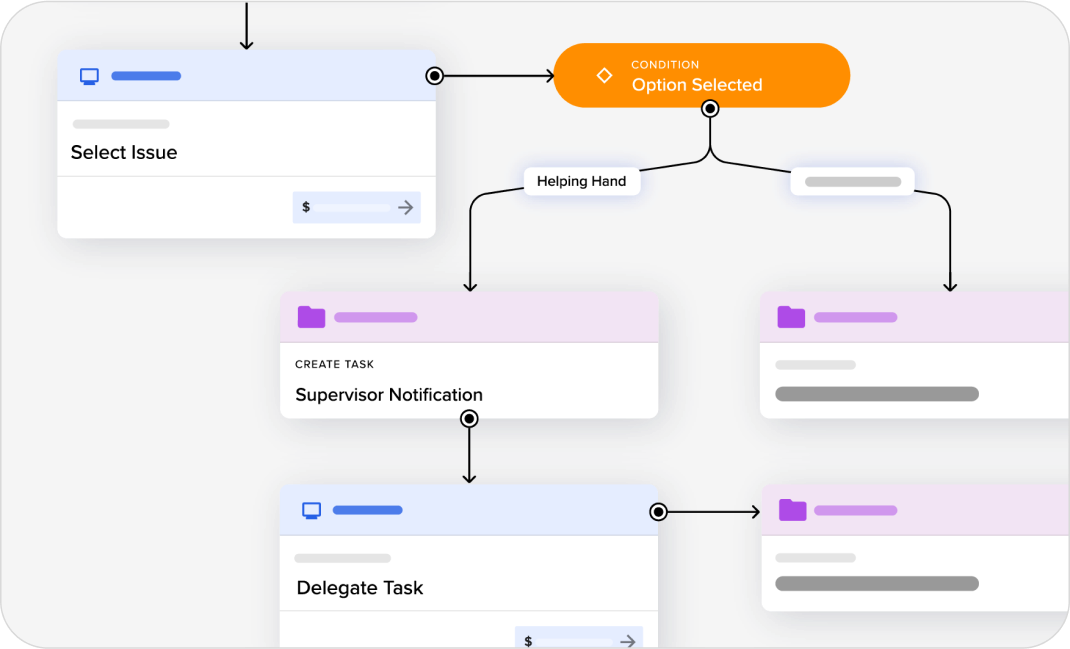

Design parallel processes

The key component to speed up changeover processes is to break the workflow into parallel streams.

By digitally coordinating all relevant workers, the total process can often be drastically shortened. Supporting workers are only called in for specific tasks when they are needed and otherwise continue value adding activities in other areas.

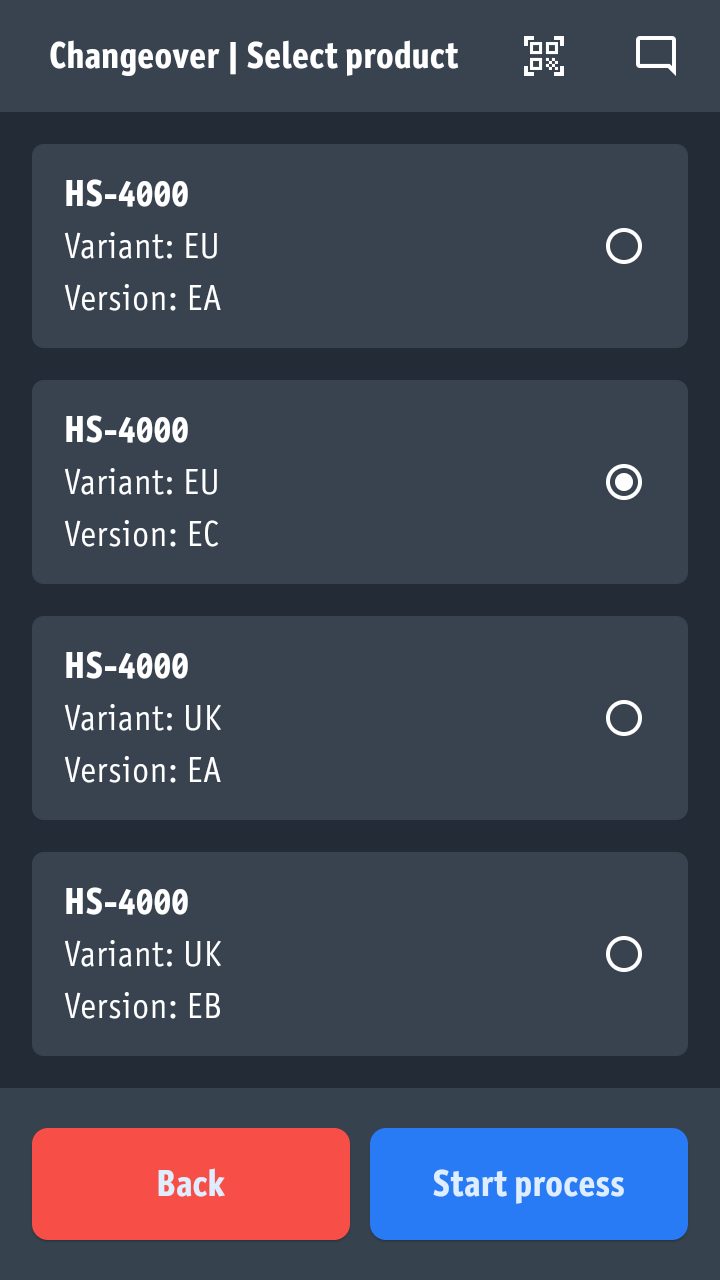

Distribute work based on roles and skills

Automatically assign tasks to the respective workers based on skills required.

The Workerbase task management system automatically controls the whole flow and dynamically assigns tasks to other workers when they are required in the process. Just tag a task with a skill and the system runs the coordination based on the actual timings.

Discover Why Industry Leaders Use Workerbase

We’d love to walk you through how our platform can solve your specific manufacturing and production challenges and deliver measurable results.

We’d also be happy to share more insights on how our platform tackles challenges such as:

- Information access and task related support for frontline workers

- Inflexible and siloed IT infrastructure, such as existing MES or ERPs

- Achieving data maturity from your entire manufacturing ecosystem