Machine Maintenance

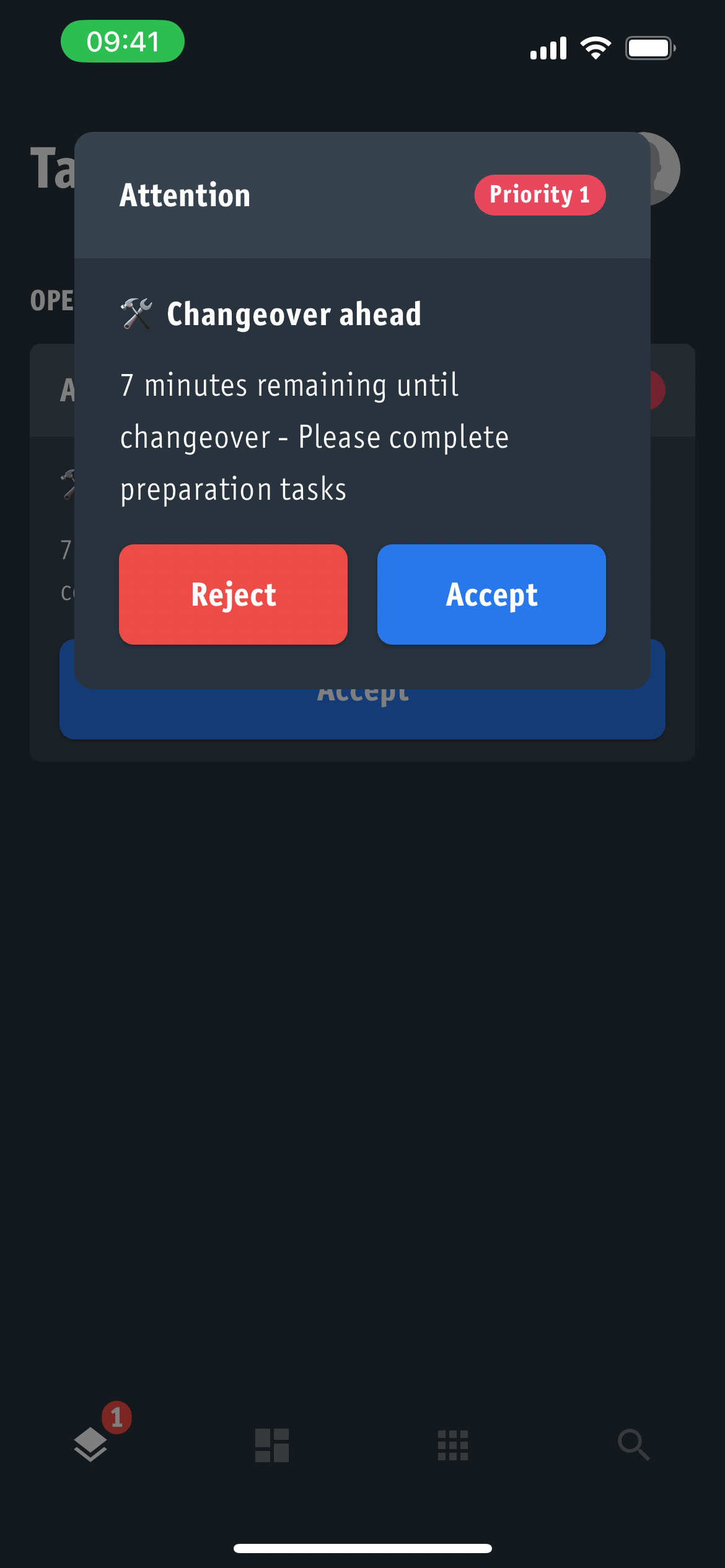

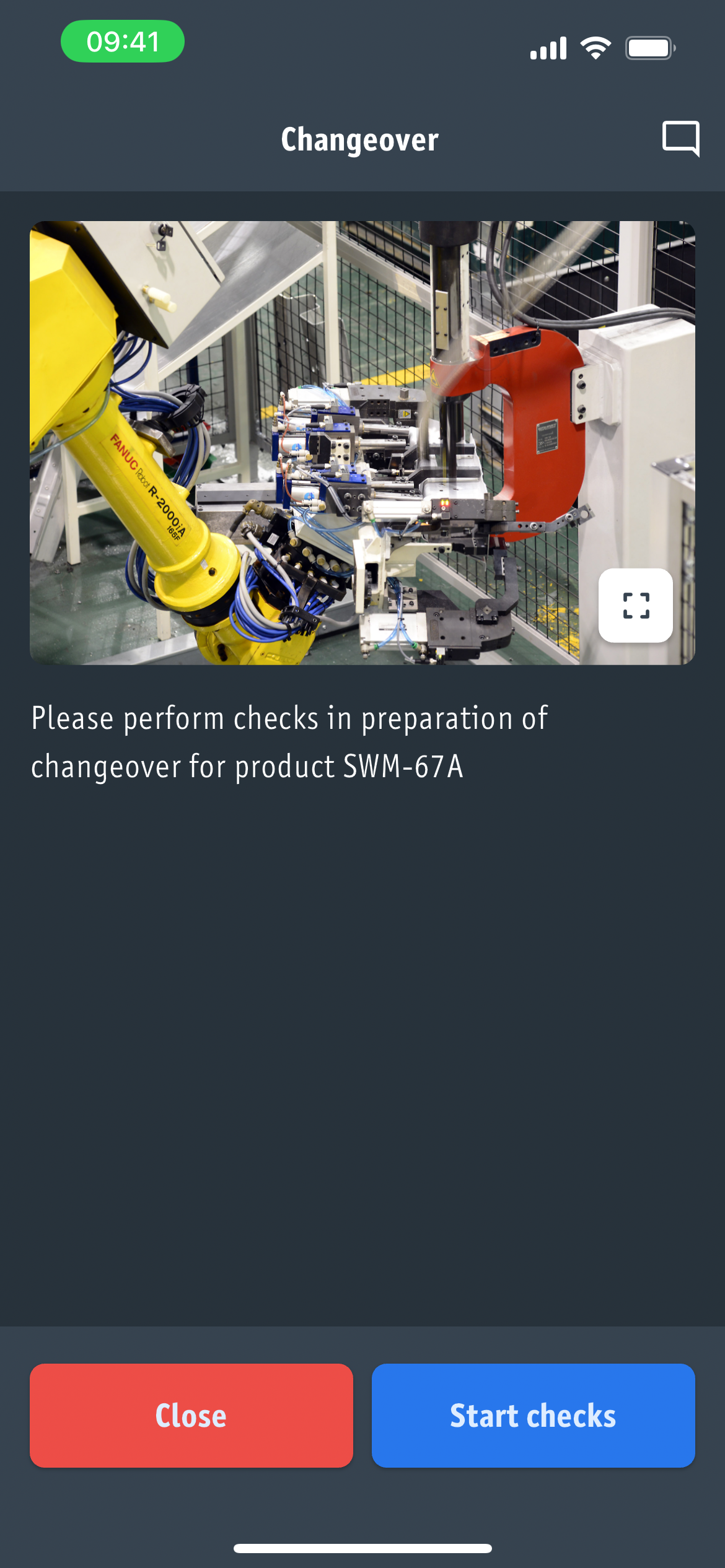

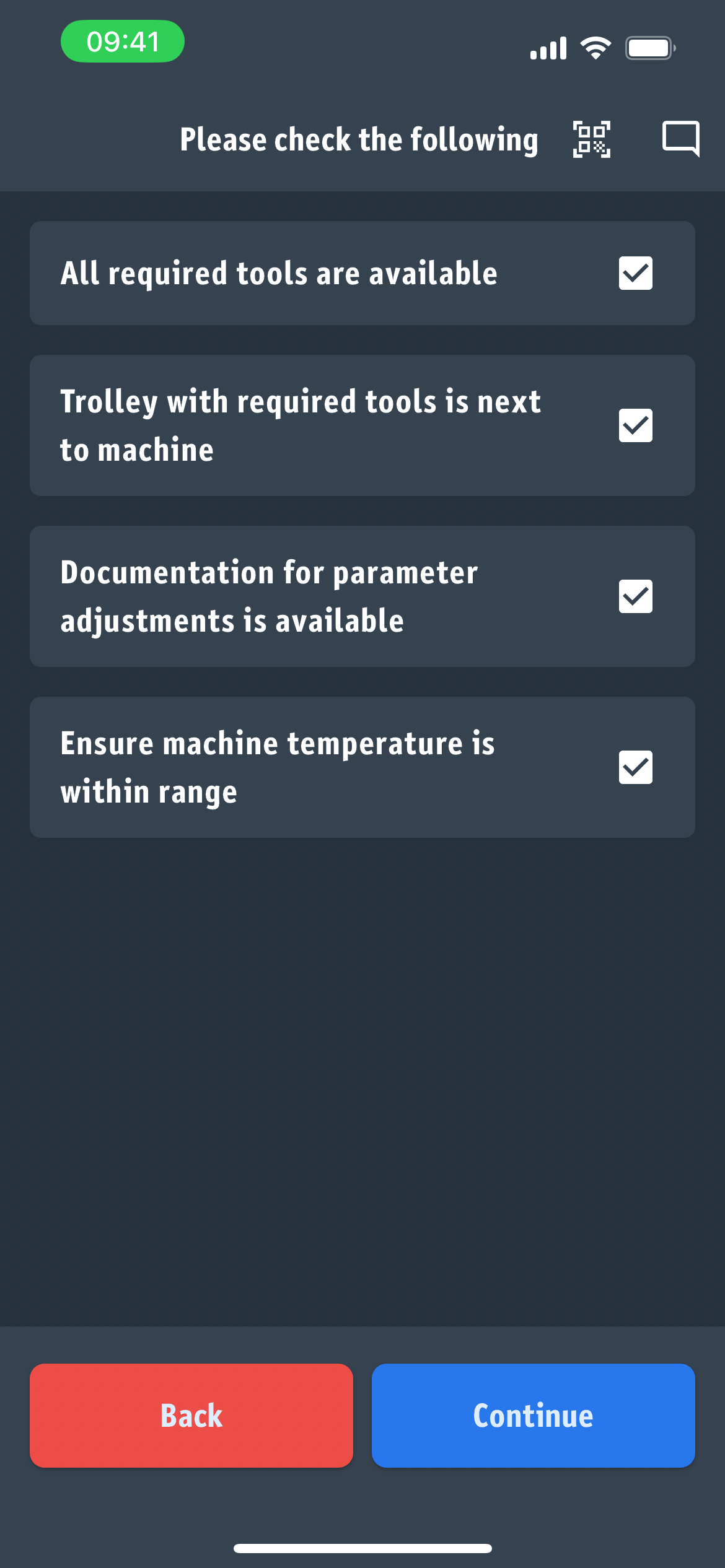

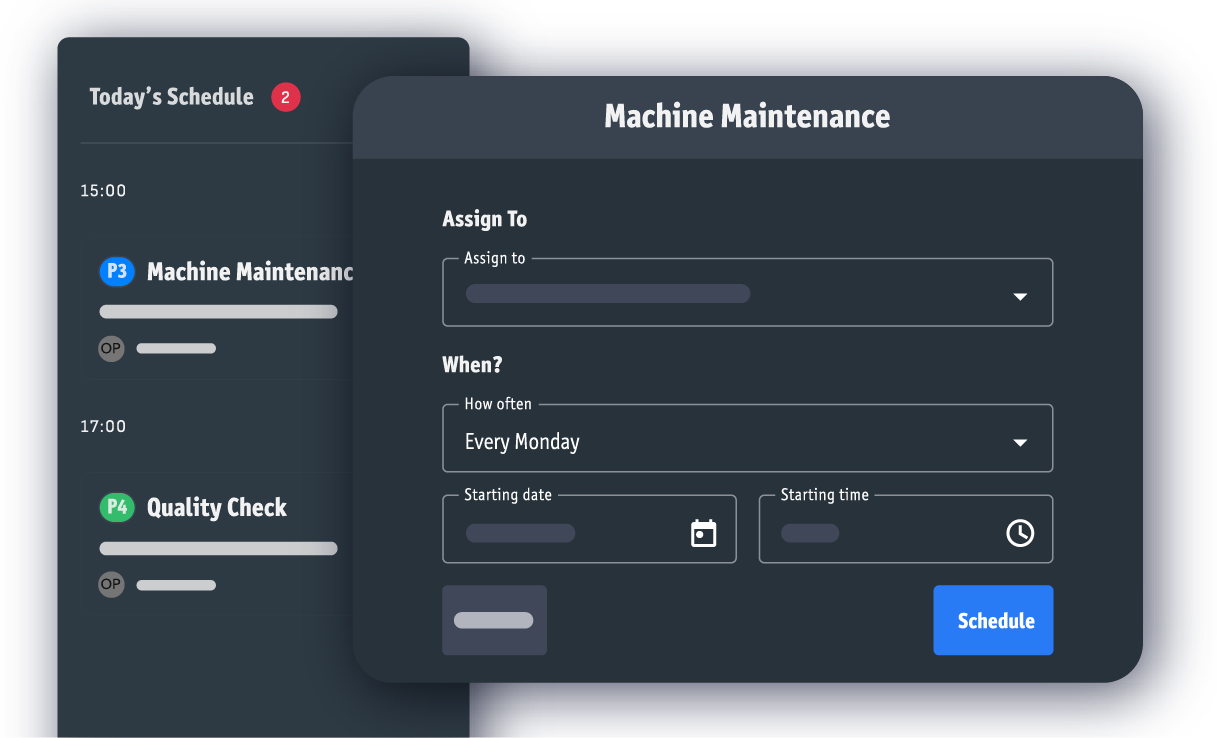

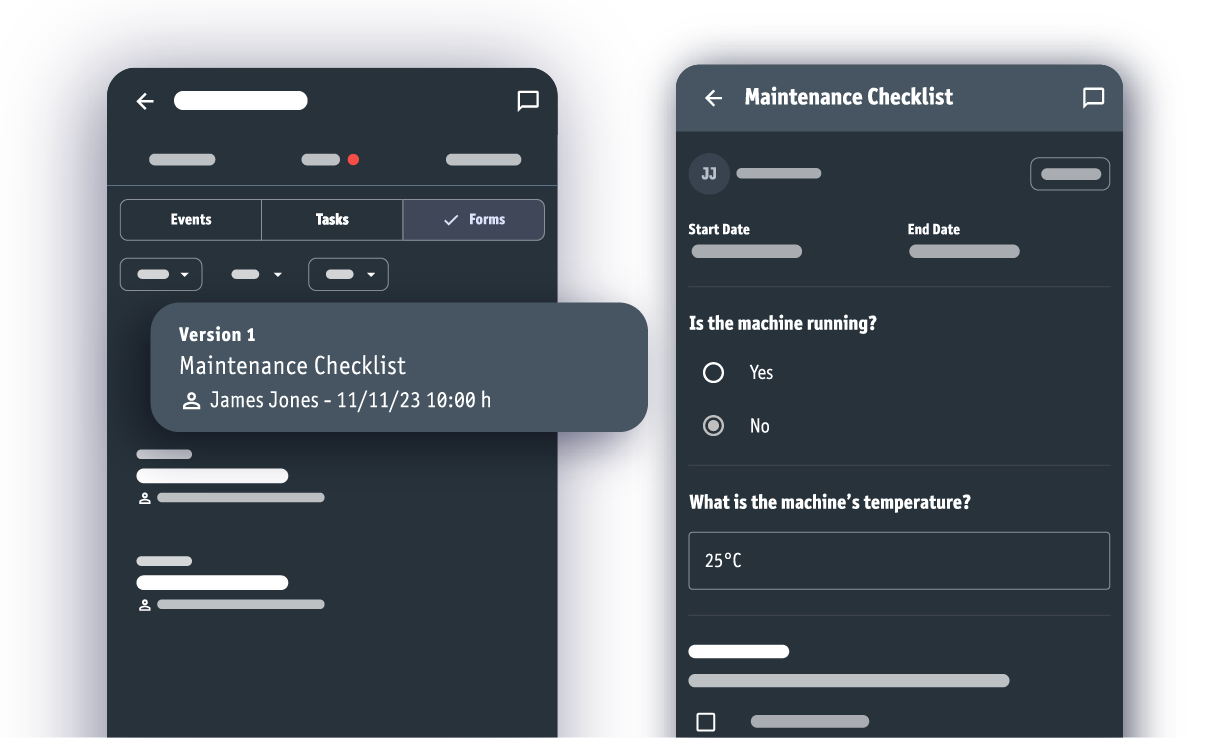

Automate the scheduling and execution of maintenance tasks, providing operators with detailed step-by-step instructions and critical machine information.

Maintenance tasks can be sent manually or automatically based on your business logic, ensuring proper documentation, reducing downtime, and increasing compliance rates.

Maintenance tasks can be sent manually or automatically based on your business logic, ensuring proper documentation, reducing downtime, and increasing compliance rates.

Unlock Efficiency Across Your Logistics Chain

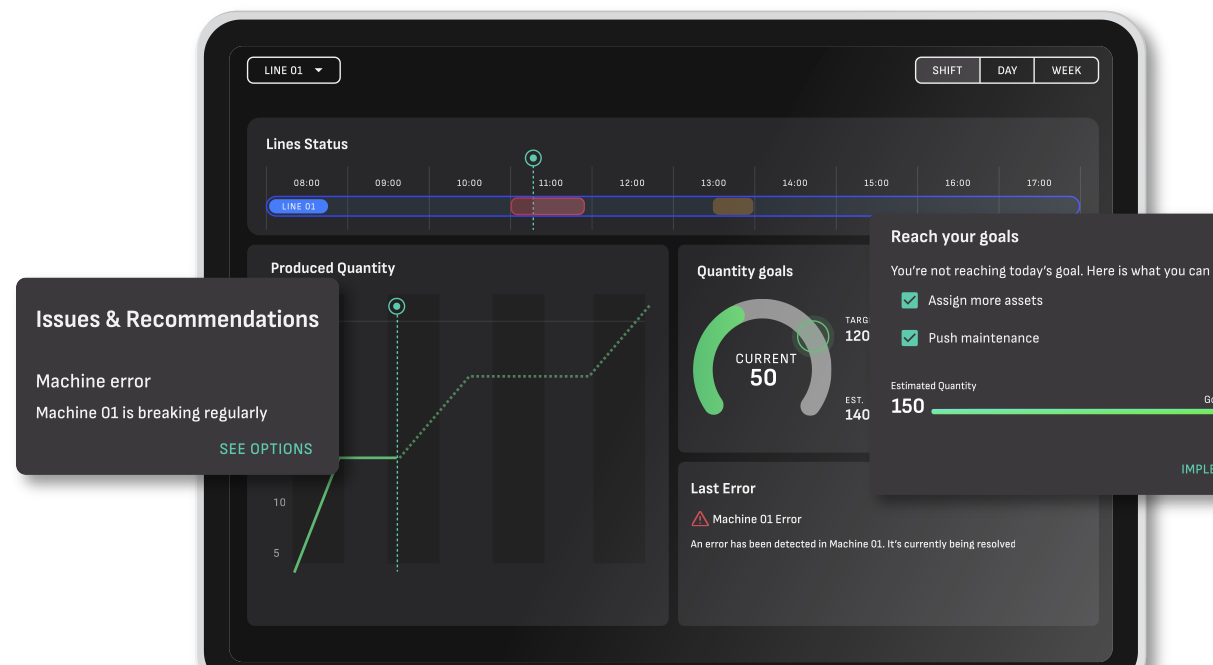

Improved Operational Performance

Streamlined workflows and faster decisions—keep production running smoothly, shift after shift.

Enhanced Compliance

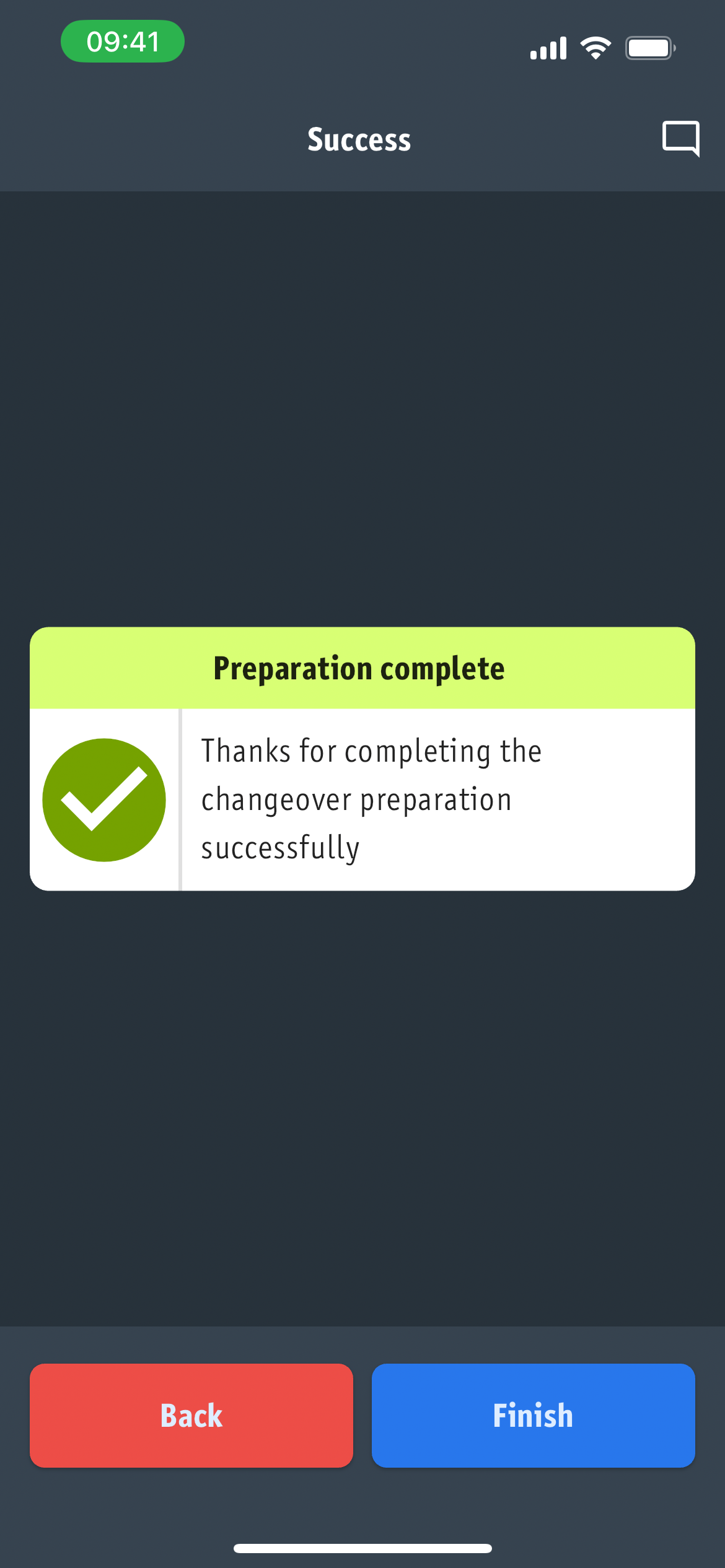

Track every step, prove every action. Gain full visibility across processes to meet compliance requirements with confidence and ease.

Reduced MTTR

Accelerate issue resolution with real-time alerts, clear responsibilities, and instant access to the right information—so machines get back up faster.

Why use the Machine Maintenance App?

Existing Processes

- Operators waste valuable time searching for logistics personnel or making phone calls to request a transport

- Traditional intralogistics processes rely on paper-based documentation, leading to lost information

- “Look and see” activities to identify transport needs consume valuable time and create inconsistent material flow

With Workerbase

- Operators can request transports directly from their workstation without interrupting their work

- Transport requests are centrally tracked, prioritized, and efficiently assigned to available logistics personnel

- Logisticians receive real-time notifications with complete transport details on their digital kanban board

Easy steps to implement Machine Maintenance

Discover Why Industry Leaders Use Workerbase

We’d love to walk you through how our platform can solve your specific manufacturing and production challenges and deliver measurable results.

We’d also be happy to share more insights on how our platform tackles challenges such as:

- Information access and task related support for frontline workers

- Inflexible and siloed IT infrastructure, such as existing MES or ERPs

- Achieving data maturity from your entire manufacturing ecosystem