If you’re managing production operations, you know the challenges: connecting machines, systems and workers in real-time isn’t easy. That’s why we’re excited to announce our partnership with HiveMQ, combining their powerful MQTT platform with our Connected Worker solution to help you reduce machine downtimes, boost worker productivity and drive quality improvements through better use of your manufacturing data.

What this means for your production floor

Think about your current setup. You probably have valuable data trapped in different systems, machines running without real-time monitoring, and workers who could make better decisions if they had the right information at the right time. Our partnership with HiveMQ tackles these challenges head-on.

Three ways this partnership optimize your operations

1. Real-time data that actually works

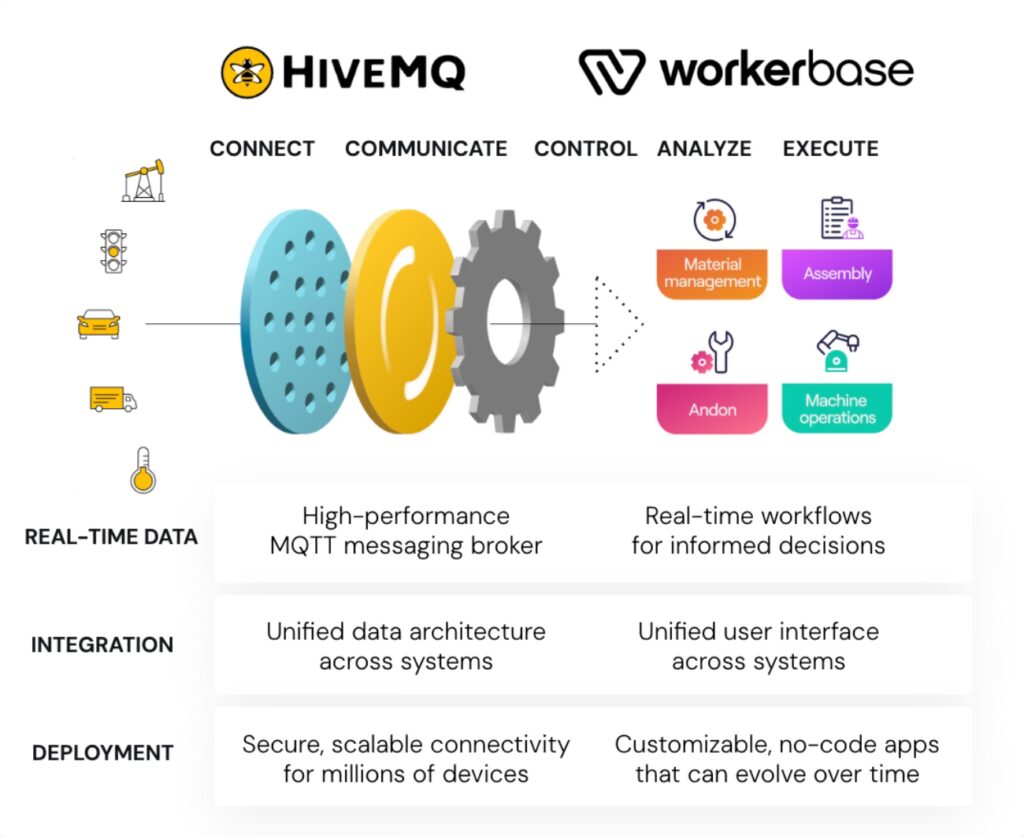

Traditional manufacturing setups often have delays of minutes before machine data reaches operators – like a machine alarm that doesn’t get to maintenance teams until it’s too late. HiveMQ’s high-performance MQTT messaging broker eliminates these delays by streaming machine data in real-time, while Workerbase’s intelligent workflows turn this data into actionable insights. Your team gets instant alerts and clear action steps on their mobile devices, whether they’re handling material management, Andon calls, or machine operations. The result? Our customers report reducing average response times by over 50% and preventing small issues from becoming costly line stops.

2. Integration: Connect everything without replacing anything

Keep your existing systems like ERP and MES while making them work better together. HiveMQ provides a unified data architecture while Workerbase delivers a unified user interface across all your systems. This means your machines, systems, and workers connect into one digital workflow – whether you’re working with older equipment or the latest IoT sensors. No more switching between different applications; your workers get all the information they need through one simple interface, while your machines and systems communicate seamlessly in the background.

3. Deployment: Scale without the headaches

Start by connecting all your machines to one universal standard with HiveMQ’s MQTT platform, ensuring secure connectivity for millions of devices. This data flows automatically into Workerbase’s no-code platform, where you can:

- Create intelligent workflows that route machine alarms to the right people in seconds, not minutes

- Analyze patterns in your machine data to identify and eliminate recurring issues before they cause downtime

- Automatically trigger preventive maintenance based on real machine behavior, not just fixed schedules

- Modify and expand your applications as your needs change, without technical limitations or complex coding

See it in action: Machine alarms that make sense

Here’s a practical example: One of our customers used to struggle with delayed responses to machine downtimes. Now, their setup works like this:

- Machine data flows continuously through HiveMQ’s MQTT platform

- Workerbase processes this data in real-time

- When an issue occurs, the right worker immediately gets an alert on their mobile device

- The alert includes exactly what they need: the problem description, location, and recommended actions

- Supervisors can track response times and resolution patterns to prevent future issues

Ready to transform your production floor?

This partnership brings together HiveMQ’s expertise in reliable data movement with Workerbase’s proven track record in making that data actionable for workers. The result? A practical solution that helps you reduce downtime, improve quality, and make better decisions faster.

Want to see how this could work in your facility? Let’s talk. Book a demo below to see these capabilities in action and discuss how we can address your specific needs.