Andon, a term derived from the Japanese word for “lantern,” has illuminated the path to excellence in lean manufacturing for decades. Much more than a tool, it’s a philosophy predicated on achieving superior efficiency, quality, and problem-solving capabilities in the factory.

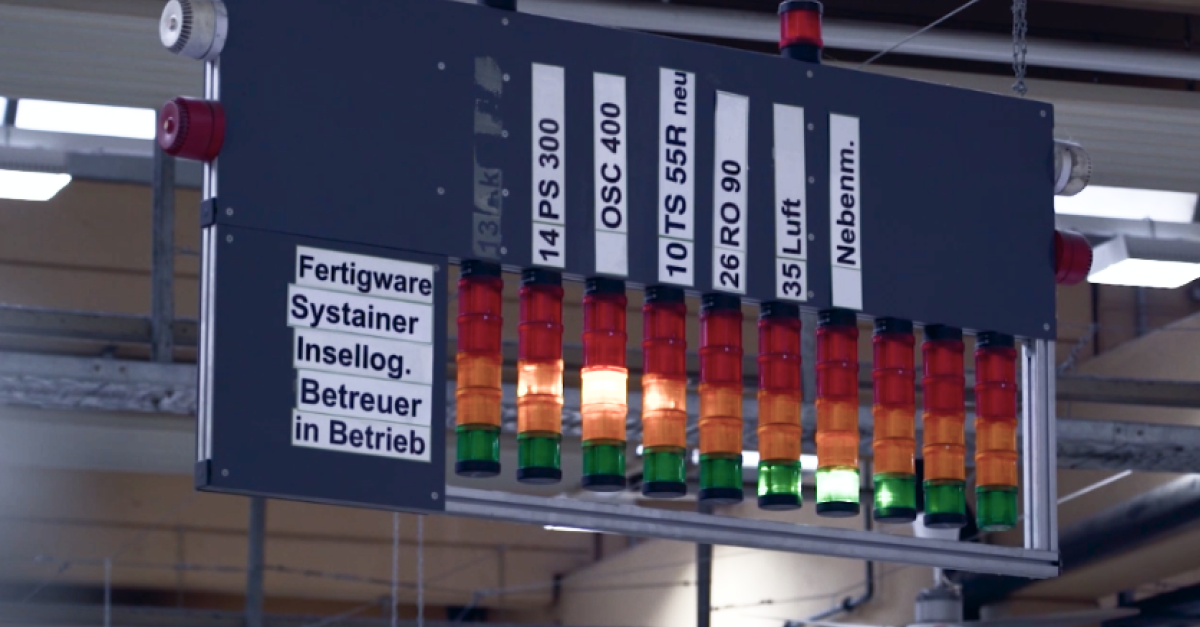

First introduced by Toyota as part of the Toyota Production System (TPS), Andon is a visual management tool that enables real-time communication of production status, issues, and performance. It involves the use of lights, displays, or signals to alert teams to deviations from the standard or to signal the need for assistance.

Andon’s Primary Objectives

- Facilitate quick problem identification and resolution.

- Promote transparency in the manufacturing process.

- Empower operators to stop production when quality or safety issues arise.

The state of Andon today

In today’s fast-paced manufacturing environment, the principles of Andon remain highly relevant. A digital Andon system provides real-time visibility into the production process, offering immediate feedback on equipment status, workflow bottlenecks, and quality control issues. It serves as the backbone of efficient, responsive, and agile factory operations. Transparency empowers both factory operators and management to make data-driven decisions swiftly, minimizing downtime and optimizing productivity.

One of the primary advantages of a digital Andon system is its role in fostering a culture of continuous improvement and employee engagement. It encourages team members to proactively identify and address issues, fostering a sense of ownership over the production process. Moreover, by collecting and analyzing data over time, factories can identify recurring problems and implement corrective measures and preventive actions to enhance overall efficiency and product quality.

The growing complexity of production processes (with more and more product variants) and increasing customer demands for quality make

Andon more critical than ever. At the end of the day, plant managers are relying on speedy responses to disruptions to keep the belts running, the product flowing and stay ahead of the growing competition.

In today’s global market, where customer demands are constantly changing and production processes are getting increasingly complex (with more and more product variants), plant managers are relying on speedy responses to disruptions to keep the belts running, the product flowing and stay ahead of the growing competition.

“The agility afforded by a digital Andon system allows factories to quickly adapt to fluctuations in demand, reconfigure production lines, and maintain high standards of quality.”

Manufacturers that embrace digital transformation reap the benefits from day one: improved throughput, reduced waiting times, increased productivity across teams and functions, and better material handling with real-time processes.

Traditional Andon methods are no longer fit for purpose

Traditionally, Andon systems in factories have relied on physical signal lights, buzzers, and manual communication. While these methods have served their purpose, they come with inherent limitations:

Delay in information flow

Traditional Andon systems introduce delays in conveying critical information, as they rely on someone manually activating the signal and face-to-face communication. This leaves room for human error and misinterpretation. What’s more, incidents are often not noticed on time because operators don’t easily recognize the yellow or red lights traditionally used as Andon visual cues.

Lack of data integration

In an era where manufacturing operations are driven by data-driven decision-making, automation, and real-time connectivity, older Andon systems lack the capability to integrate with other systems, such as an ERP or MES, machines, or smart devices. This makes it close to impossible (or extremely laborious) to gather and analyze data for continuous improvement.

Limited accessibility

In today’s globalized and interconnected manufacturing landscape, factory managers and personnel often need to access and monitor production processes and line statuses from various locations – sometimes even across different time zones. With traditional Andon systems, information is typically confined to the factory floor, making it very difficult to collaborate and monitor remotely. A system that relies on physical presence can be impractical when dealing with geographically dis