Optimizing production workflows with the Zebra WS50

Optimizing production processes is key to achieving efficiency and minimizing waste in manufacturing. One critical concept in this pursuit of lean manufacturing is centerlining.

Centerlining is a systematic approach used to ensure that a manufacturing process consistently operates at its optimal or “centered” state. This means that the process reliably produces products (or components) that meet quality standards and specifications with as little variation as possible. In other words, centerlining aims to eliminate variability in a process to achieve consistent, high-quality output.

The importance of centerlining for lean manufacturing operations

A centerlined process is pivotal to lean manufacturing, as only then does every element operate at its best – reducing defects, improving productivity, and lowering overall production costs. It’s the difference between a well-oiled machine and one that’s prone to breakdowns.

Quantifying and improving centerlining

Process capability is a key performance indicator (KPI) used to measure how well a process is centered. It’s often quantified using the Six Sigma framework, which represents a level of quality where only 3.4 defects per million opportunities are allowed. In a centerlined process, the process capability index (Cpk) is high, indicating that the process operates with minimal variation around the target or mean value. The Six Sigma framework therefore aims to improve process capability by 1) reducing variation; and 2) ensuring that a process operates within defined limits.

The Six Sigma methodology involves Define, Measure, Analyze, Improve, and Control (DMAIC) phases. By systematically addressing factors causing variation, manufacturers can bring their processes closer to the optimal center, achieving higher process capability.

Centerlining for the factory of the future

Traditionally, centerlining in factories involved manual data collection, relying on operators’ experience to make adjustments. This method is time-consuming, subject to human error, and lacks real-time insights. Additionally, it can’t effectively capture subtle variations that affect processes.

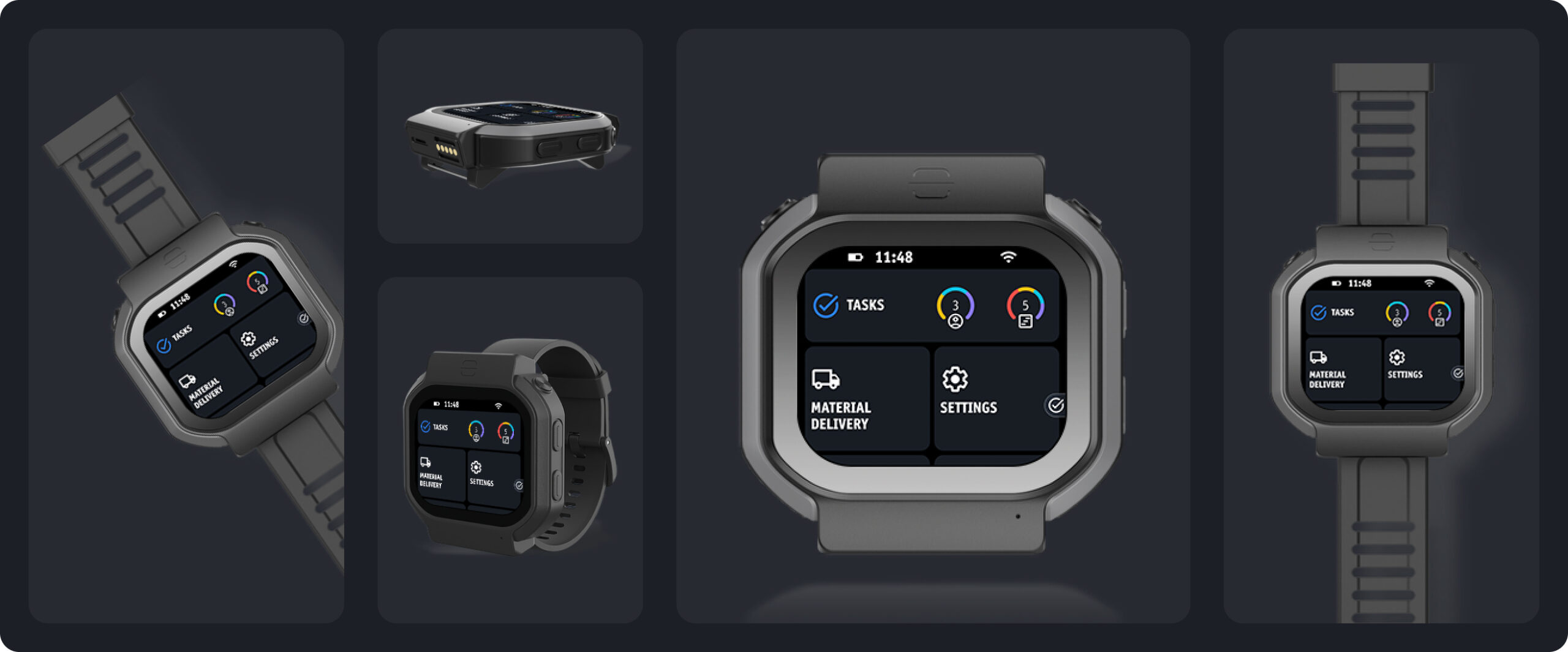

Digital tools are revolutionizing the concept of centerlining by providing real-time data collection, analysis, and visualization. Workerbase’s Connected Worker platform, for example, empowers workers with wearable devices and mobile applications that connect them to data and processes, facilitating centerlining in several ways:

• Real-time monitoring:

Operators can monitor critical process parameters in real time, and are empowered to make immediate adjustments to keep the process centered.

• Data analytics:

A Connected Worker platform collects and analyzes data, identifying patterns and trends that can lead to process variations. It helps in proactively addressing issues before they affect product quality and feeds the continuous improvement loop.

• Remote expert support:

Frontline operators are able to connect with experts remotely, and get the instant support they need to ensure that any deviations from the centered state can be quickly resolved. Without having to waste time walking around the factory trying to find a supervisor, or on the phone trying to reach someone who doesn’t pick up.

Examples: Here’s how Workerbase can help improve centerlining

• Automotive:

In an automotive assembly line, Workerbase’s platform ensures that torque values for critical components are consistently centered. Workers receive real-time feedback on torque values, reducing the likelihood of under or over-tightening bolts.

• Machinery:

In the heavy equipment manufacturing sector, Workerbase’s platform is instrumental in achieving and preserving optimal centering. Real-time monitoring ensures the alignment of components and the calibration of essential parts. This capability allows operators to make immediate adjustments, ensuring that each piece of heavy equipment is manufactured precisely to specifications, reducing the likelihood of post-production issues and enhancing overall machinery performance.

• Electronics:

Let’s take the example of circuit board assembly. Operators can monitor critical parameters such as soldering temperatures, component placements, and soldering times real-time. Any deviations from the centered state trigger immediate alerts, displayed on their smartwatch, allowing operators to make swift adjustments. This ensures that each circuit board is assembled with pinpoint accuracy, reducing defects and guaranteeing the reliability and functionality of the ensuing electronic devices.

Centerlining is even more important – and easier than ever – in the digital factory

Imagine trying to hit a bullseye on a target with darts. Centerlining is akin to adjusting your aim so that every dart consistently hits the center of the bullseye. When your aim is centered, you waste fewer darts, and you achieve better results with minimal effort.

As manufacturing evolves, centerlining is moving into the digital age, ensuring that processes remain centered and efficient in an ever-changing world of production. Tools like Workerbase’s Connected Worker platform take centerlining to the next level by providing real-time monitoring, data analytics, and connecting workers to expert support.

Have we piqued your interest?