Staying ahead of the competition requires more than just efficient production lines. It demands a comprehensive understanding of every step in the production process, from raw materials to finished products. This article delves into the transformative world of traceability software, exploring how these digital tools are reshaping manufacturing processes, enhancing quality control, and providing unprecedented visibility across the product value chain. Whether you’re a seasoned industry professional or new to the concept, this in-depth guide will equip you with the knowledge to leverage traceability solutions for improved transparency, compliance (such as the digital product passport), and customer satisfaction in your manufacturing operations.

Understanding traceability in manufacturing

Traceability in manufacturing refers to the ability to track and document the journey of a product from its inception to its final destination. This comprehensive approach encompasses every stage of the production process, including the sourcing of raw materials, various manufacturing steps, quality control checks, and ultimate delivery to the end customer. The concept of traceability has evolved significantly over the years, transitioning from manual record-keeping to sophisticated digital systems like that offer real-time insights and data-driven decision-making capabilities.

The evolution of traceability software & systems

Historically, traceability in manufacturing relied heavily on paper-based systems and manual data entry. This approach was not only time-consuming but also prone to errors and inefficiencies. As technology advanced, basic computerized systems emerged, offering improved data storage and retrieval capabilities. However, these early digital solutions often operated in silos, lacking the integration necessary for a holistic view of the production process.

The advent of modern traceability software marks a significant leap forward in manufacturing intelligence. These advanced systems leverage cutting-edge technologies such as the Internet of Things (IoT) to create a seamless, interconnected network of data points throughout the production lifecycle. This evolution has transformed traceability from a reactive tool for problem-solving into a proactive strategy for continuous improvement and innovation.

Key components of effective traceability software

An effective traceability system in manufacturing comprises several crucial components:

- Data collection: Automated sensors and digital forms or checklists gather real-time data at various points in the production process.

- Data storage: Secure, scalable databases store vast amounts of production and supply chain information.

- Data analysis: Advanced analytics tools process collected data to generate actionable insights.

- Reporting and visualization: User-friendly interfaces present complex data in easily understandable formats.

- Integration capabilities: Seamless connection with existing enterprise systems ensures a unified flow of information.

These components work in concert to create a comprehensive traceability ecosystem that spans the entire manufacturing operation, from supplier management to customer delivery.

The impact of traceability on manufacturing operations

Implementing robust traceability software can have far-reaching effects on manufacturing operations:

- Better compliance: Detailed record-keeping simplifies adherence to industry regulations and standards.

- Enhanced quality control: Real-time monitoring allows for immediate identification and resolution of quality issues.

- Improved efficiency: Data-driven insights help optimize production processes and reduce waste.

- Increased customer trust: Transparency in the production process builds confidence in product quality and safety.

- Faster problem resolution: When issues arise, traceability data enables quick root cause analysis and targeted solutions.

The role of digital tools in implementing traceability

Digital tools play a pivotal role in implementing effective traceability systems within manufacturing environments. These advanced technologies transform raw data into valuable insights, enabling manufacturers to make informed decisions and maintain a competitive edge in the industry.

IoT sensors and data collection devices

The foundation of any robust traceability system lies in its ability to gather accurate, real-time data from various points in the production process. IoT sensors and data collection devices serve as the eyes and ears of the traceability network, continuously monitoring and recording crucial information such as:

- Temperature and humidity levels in storage areas

- Machine performance metrics

- Production line speeds and throughput

- Quality control measurements

- Material flow and inventory levels

Advanced analytics and machine learning

The true power of traceability software lies in its ability to transform raw data into actionable insights. Advanced analytics and machine learning algorithms play a crucial role in this process by:

- Identifying patterns and trends in production data

- Predicting potential quality issues before they occur

- Optimizing production schedules based on historical performance

- Detecting anomalies that may indicate equipment failure or process inefficiencies

These intelligent systems continuously learn and adapt, becoming more accurate and valuable over time as they process increasing amounts of data.

User friendly interfaces and visualization tools

Even the most sophisticated traceability system is only as effective as its user interface. Modern traceability software incorporates intuitive interfaces and visualizations that make it easy for operators, managers, and executives to:

- Monitor real-time production metrics

- Generate custom reports on key performance indicators

- Drill down into specific areas of concern

- Share insights across departments and with stakeholders

By presenting complex data in easily digestible formats, these interfaces empower decision-makers at all levels of the organization to take prompt, informed action.

Implementing traceability software in discrete manufacturing

Discrete manufacturing, which involves the production of distinct items such as electronics, automobiles, or furniture, presents unique challenges and opportunities for traceability implementation. The complex nature of these products, often comprising numerous components from various suppliers, requires a sophisticated approach to tracking and documentation. This has resulted in new digital developments like like digital product passports that have become standard practice over time.

Mapping the production process

The first step in implementing traceability software in discrete manufacturing is to create a comprehensive map of the production process. This involves:

- Identifying key stages in the manufacturing workflow

- Determining critical control points for data collection

- Mapping the flow of materials and components through the facility

- Identifying potential bottlenecks or areas of concern

This detailed mapping serves as the foundation for designing a traceability system that captures all relevant information without disrupting the production flow.

Integrating with existing systems

Most discrete manufacturers already have various systems in place, such as Enterprise Resource Planning (ERP) software, Manufacturing Execution Systems (MES), and Quality Management Systems (QMS). Effective traceability software must seamlessly integrate with these existing platforms to ensure:

- Consistent data flow across all systems

- Elimination of data silos and information gaps

- Reduced manual data entry and potential for errors

- A unified view of the entire manufacturing operation

Implementing digital product passports

A digital product passport is an innovative application of traceability software in discrete manufacturing. This electronic record accompanies a product throughout its lifecycle, containing detailed information about:

- Raw materials used in production

- Manufacturing processes and quality checks performed

- Compliance certifications and test results

- Maintenance and repair history

- End-of-life recycling instructions

Digital product passports not only enhance traceability but also support sustainability initiatives by providing valuable information for recycling and responsible disposal of products at the end of their useful life.

Selecting the right traceability software for your manufacturing operation

Choosing the appropriate traceability software is a critical decision that can significantly impact the success of your implementation. Several key factors should be considered to ensure the selected solution aligns with your specific manufacturing needs and objectives.

Assessing your traceability requirements

Before evaluating specific software options, it’s essential to conduct a thorough assessment of your traceability requirements:

- Identify the specific processes and products that require traceability

- Determine the level of granularity needed in your traceability data

- Consider any industry-specific regulations or standards that must be met

- Evaluate your current IT infrastructure and integration requirements

- Assess the scalability needs of your operation

This assessment will provide a clear framework for evaluating potential traceability solutions and ensure that the selected software can meet your current and future needs.

Key features to look for in traceability software

When evaluating traceability software options, consider the following key features:

- Real-time data collection and processing capabilities

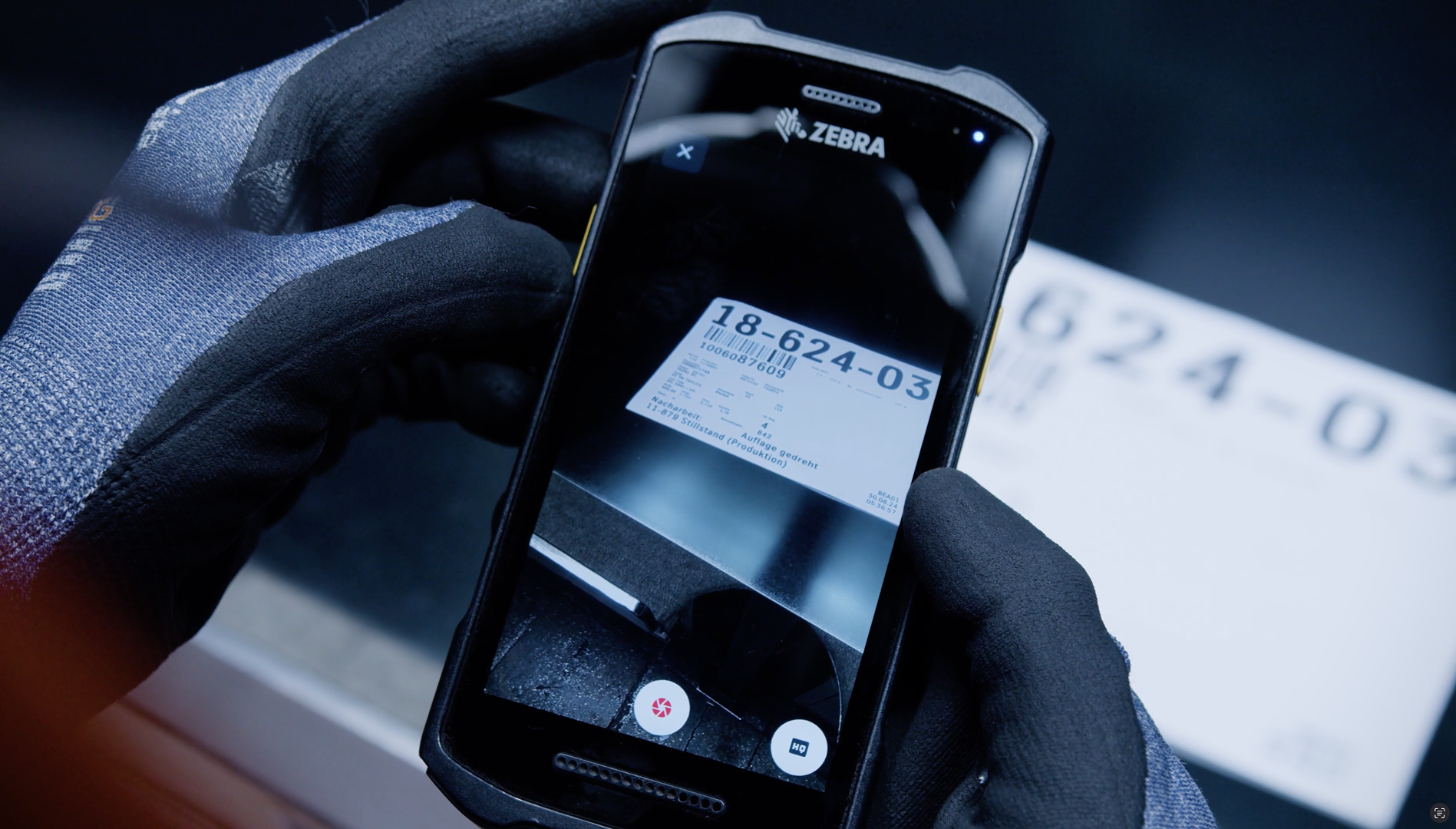

- Flexible data input options (barcode scanners, RFID, manual entry, etc.)

- Robust reporting and analytics tools

- User-friendly interfaces for operators and managers

- Integration capabilities with existing ERP, MES, and quality systems

- Scalability to accommodate business growth

- Mobile access for on-the-go monitoring and decision-making

- Customization options to fit your specific processes and workflows

Prioritize these features based on your specific requirements to guide your selection process.

Conclusion: The future of manufacturing traceability

As we’ve explored throughout this article, traceability software has become an indispensable tool for modern manufacturers, offering unprecedented visibility, control, and efficiency across the production process. From enhancing quality control and regulatory compliance to optimizing operations and building customer trust, the benefits of robust traceability systems are clear and far-reaching.

Manufacturers who embrace these innovations and integrate them into their operations will be well-positioned to thrive in an increasingly competitive and regulated global marketplace.

However, successful implementation of traceability software requires more than just technological prowess. It demands a strategic approach, careful planning, and a commitment to ongoing optimization and improvement. By following the best practices and strategies outlined in this article, manufacturers can maximize the value of their traceability investments and lay the foundation for long-term success in the digital age of manufacturing.

As the manufacturing landscape continues to evolve, one thing is certain: traceability will remain a critical factor in driving efficiency, quality, and trust in the production process. Those who master the art and science of traceability will be well-equipped to meet the challenges and opportunities of tomorrow’s manufacturing environment.