Just-in-time digital workflows to increase throughput in the automotive industry.

Trusted by the world’s best companies

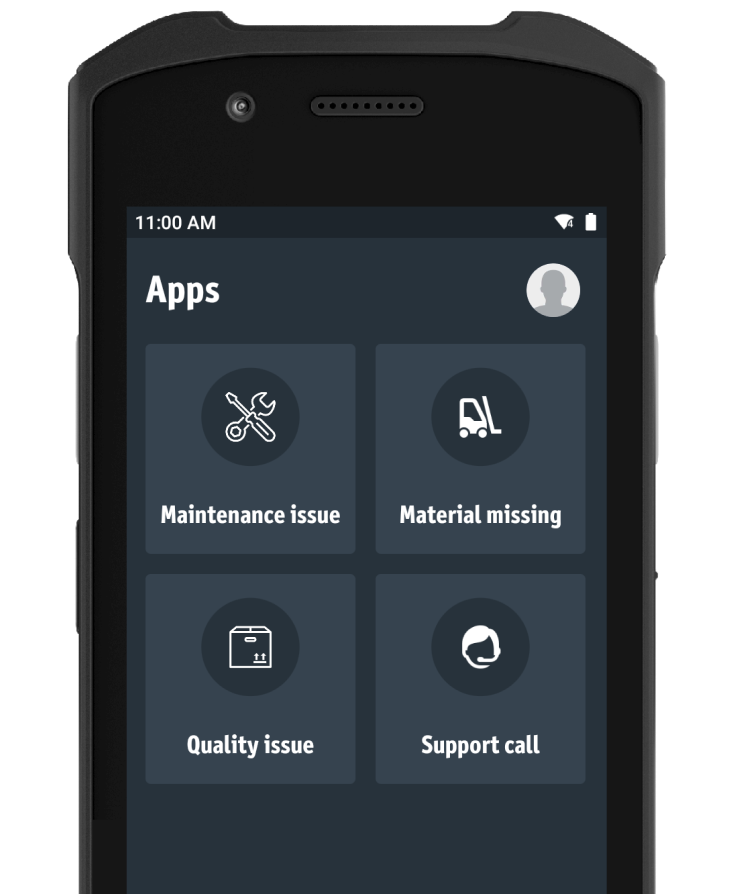

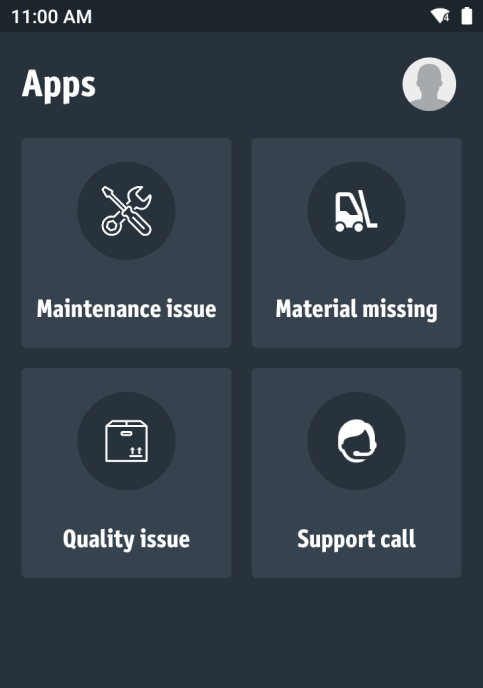

Connected Worker Apps for vehicle production

From tackling material shortages to managing high product variants, our Connected Frontline Worker apps boost efficiency and ensure just-in-time digital workflows that drive improved throughput.

Explore our Connected Worker apps for the automotive industry

Andon

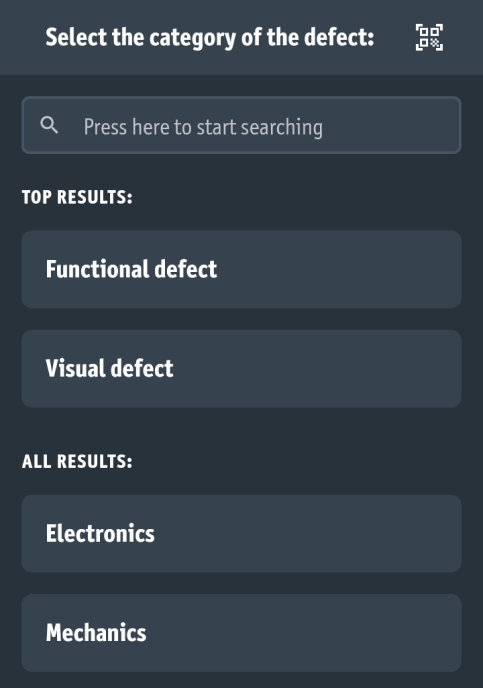

Non-conformities

Digital checklists

Drive operational excellence: continuous

Machine alarm

Rework

Real-time coordination of rework processes to increase throughput

Reworking faulty items costs a large amount of resources. Establishing lean processes in this area is particularly difficult because rework tasks change frequently and rely primarily on manual labor. To establish lean and flexible processes, your workforce needs to be connected in real-time. We provide mobile interfaces to existing systems, thereby reducing reaction times and accelerating decision making.

Preventing belt stops

When your frontline workers are connected to a realtime information pool, the Workerbase system can predict disruptions before they occur. This allows you to take preventive action and reduce stops of your final assembly line to a minimum.

Platform functions designed for the automotive industry

Task automation

Workerbase automatically orchestrates tasks based on real-time data. Workflows are triggered without manual intervention when the previous phase is completed.

Task assignment

Workerbase automatically assigns tasks to the right person in case of process disruptions, e.g. missing material at the assembly line. Critical tasks receive attention when needed.

Alerts

Workerbase automatically alerts staff when action is needed, e.g. if a vehicle needs rework, the platform informs the driver that car movement is needed.

Escalation levels

Workerbase automatically moves a task to the next escalation level if it’s not picked up and needs urgent action.

Delegation

Workerbase automatically assigns a task to someone more suited. All delegation rules can be adjusted to meet custom needs.

Team coordination

Our digital workflows facilitate efficient team processes, e.g. best practise sharing, Andon support calls, One-point lessons

Identify areas for continuous improvements

React in real-time to quality issues