1.

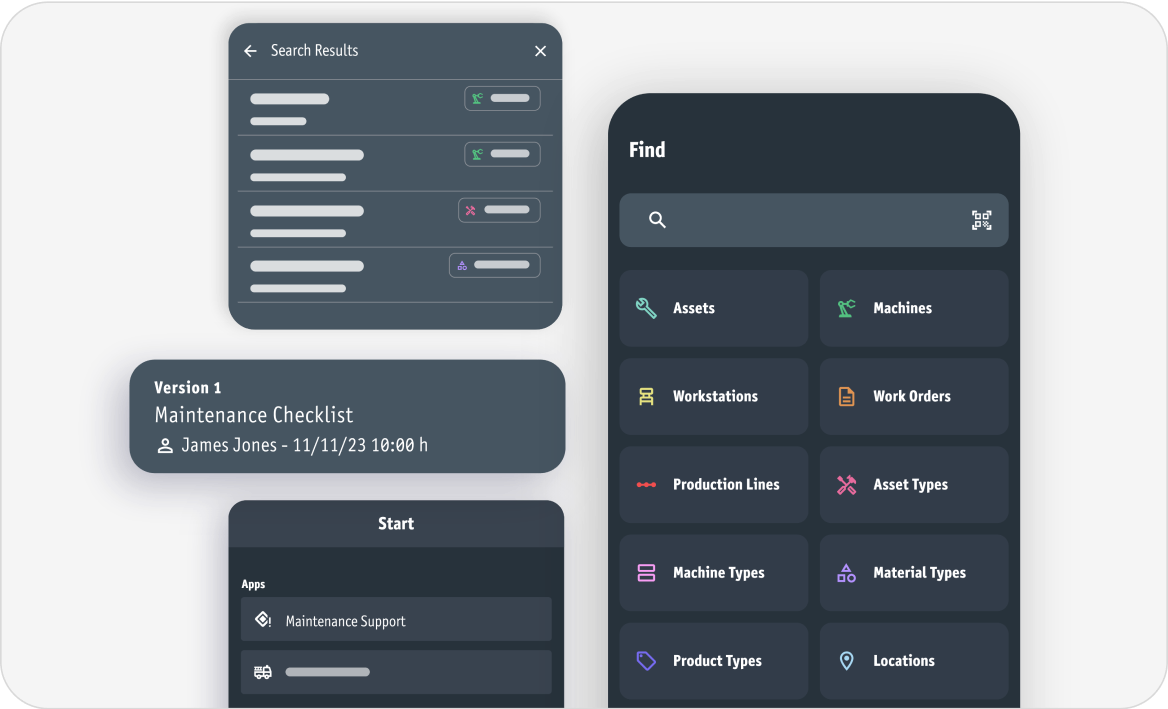

Connect Your Entire Manufacturing Ecosystem

- Connect your systems with over 100 integrations supported

- Gain access all of your systems on one central interface

- No lengthy migration or transition needed

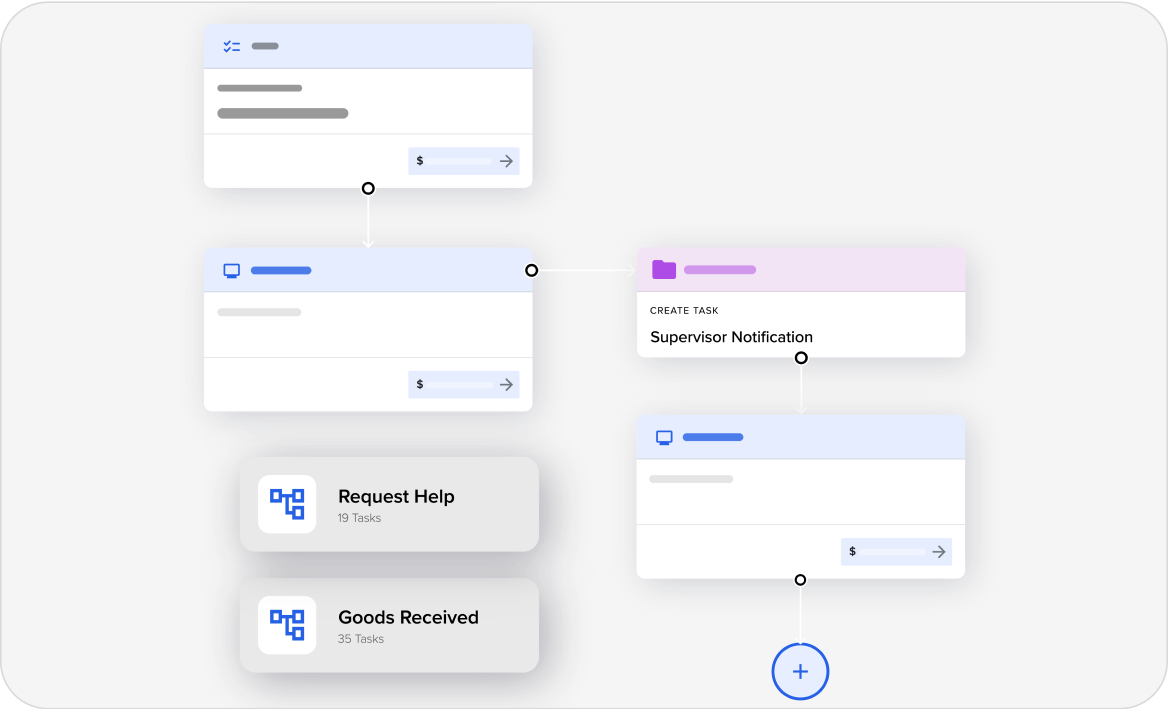

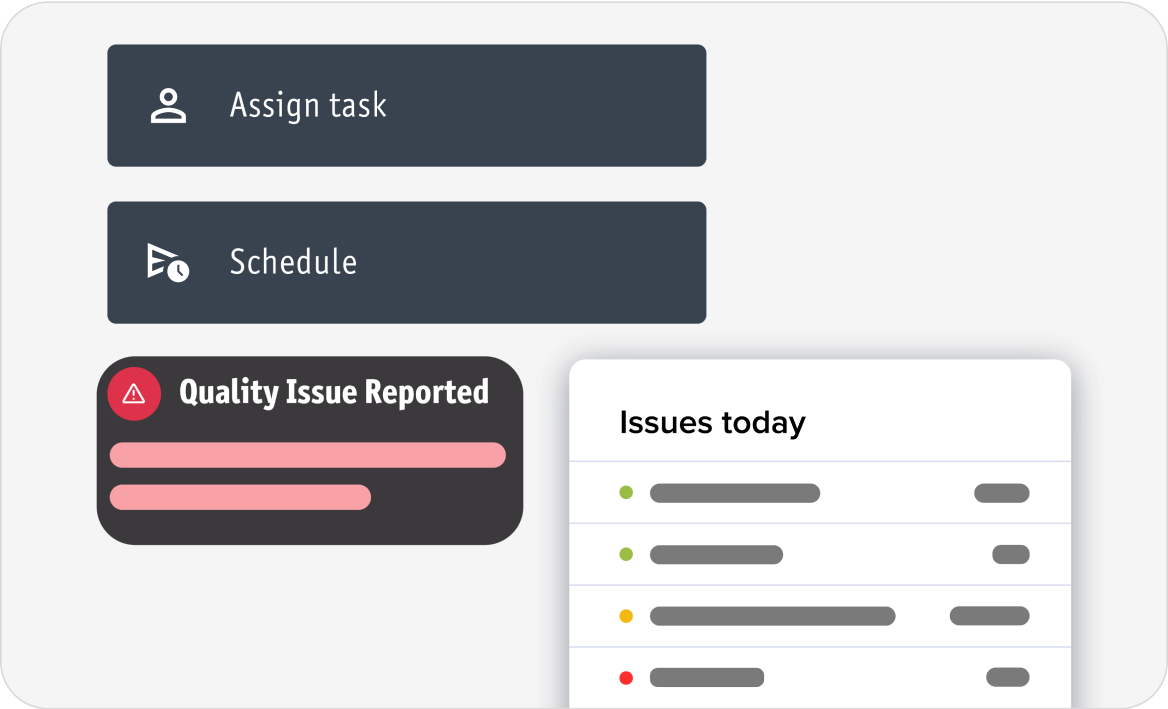

2.

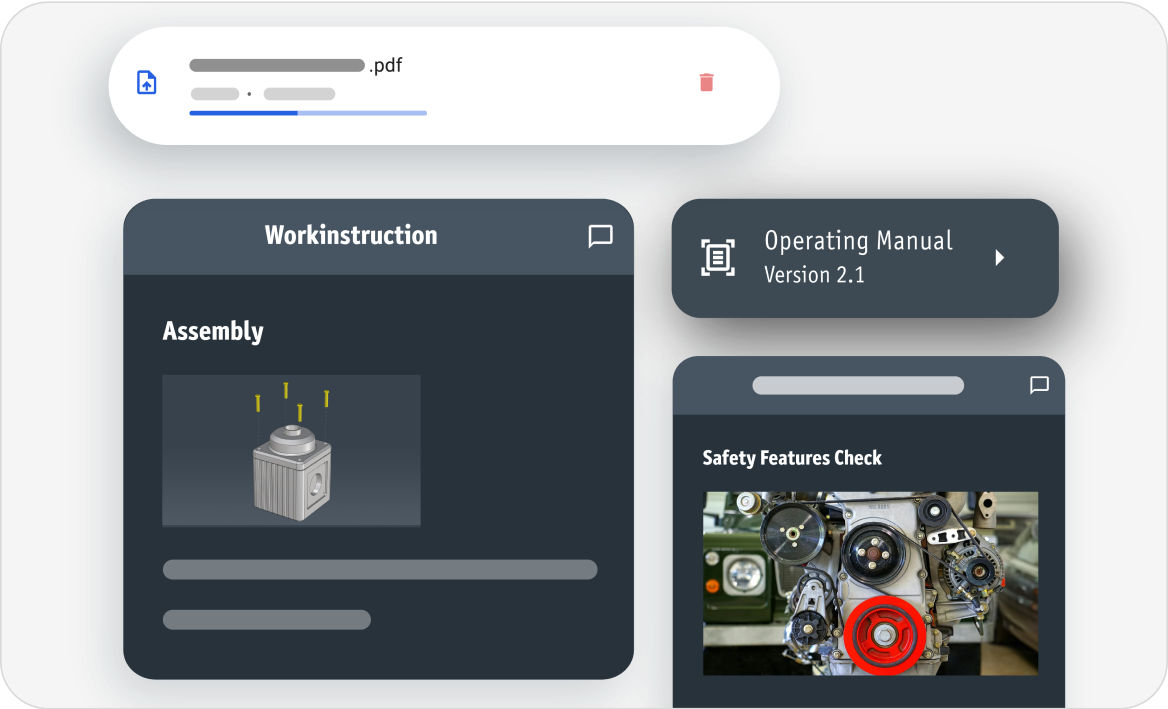

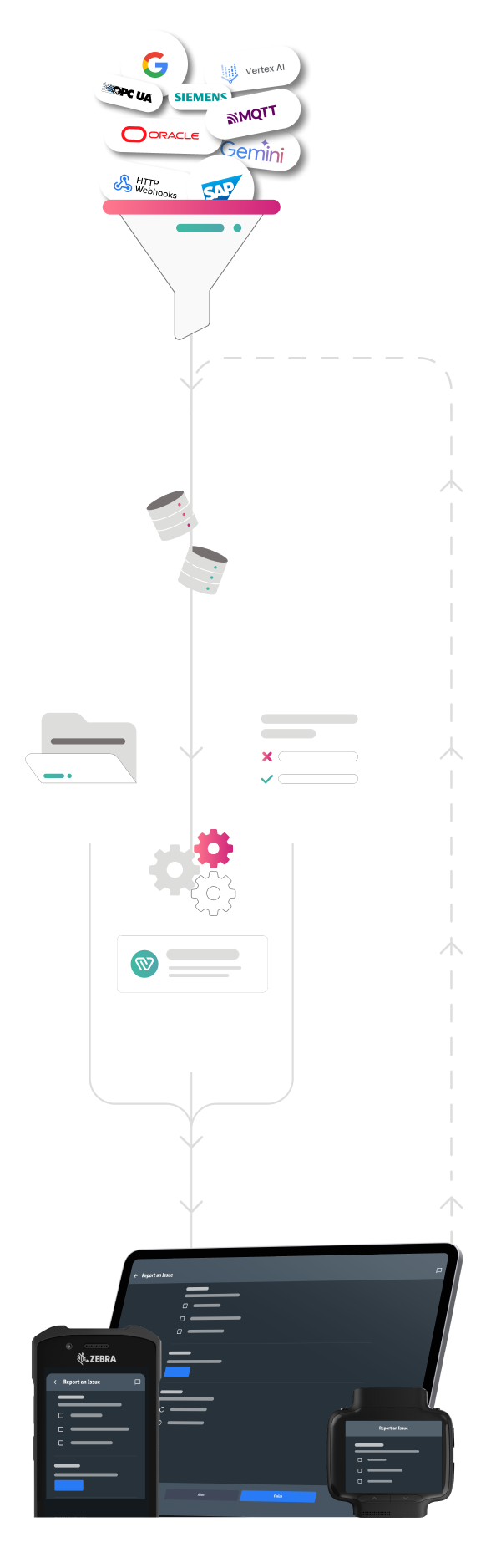

Build Workflows and Apps to Digitize Operations

- Automate the flow of tasks and data based real time events

- Access over 25 apps built to for common challenges

- Shorten IT development cycles for new solutions

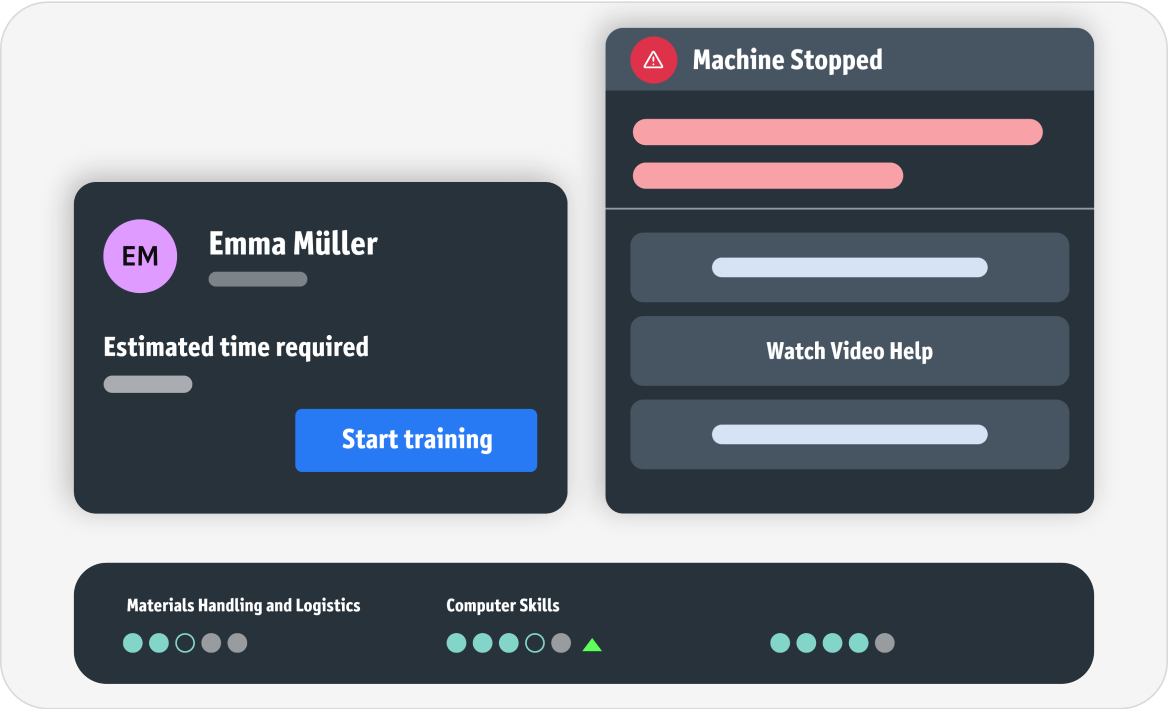

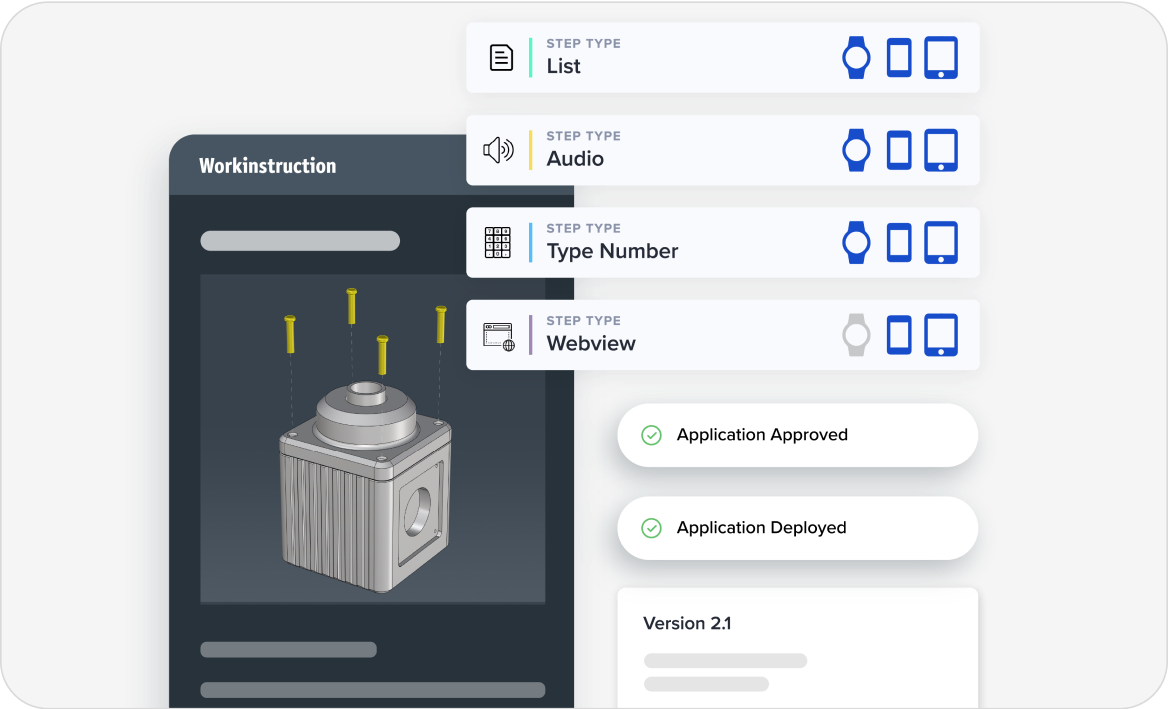

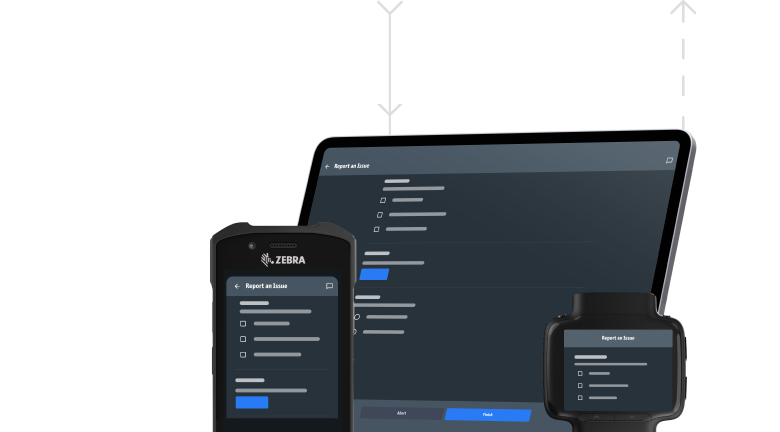

3.

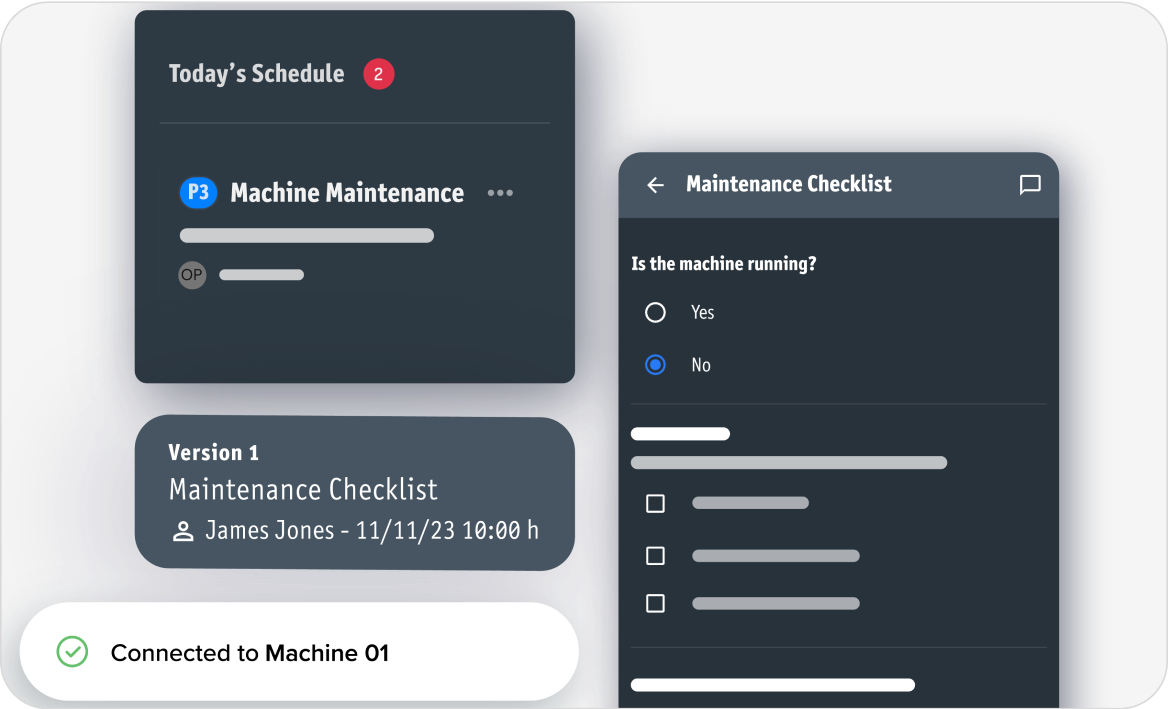

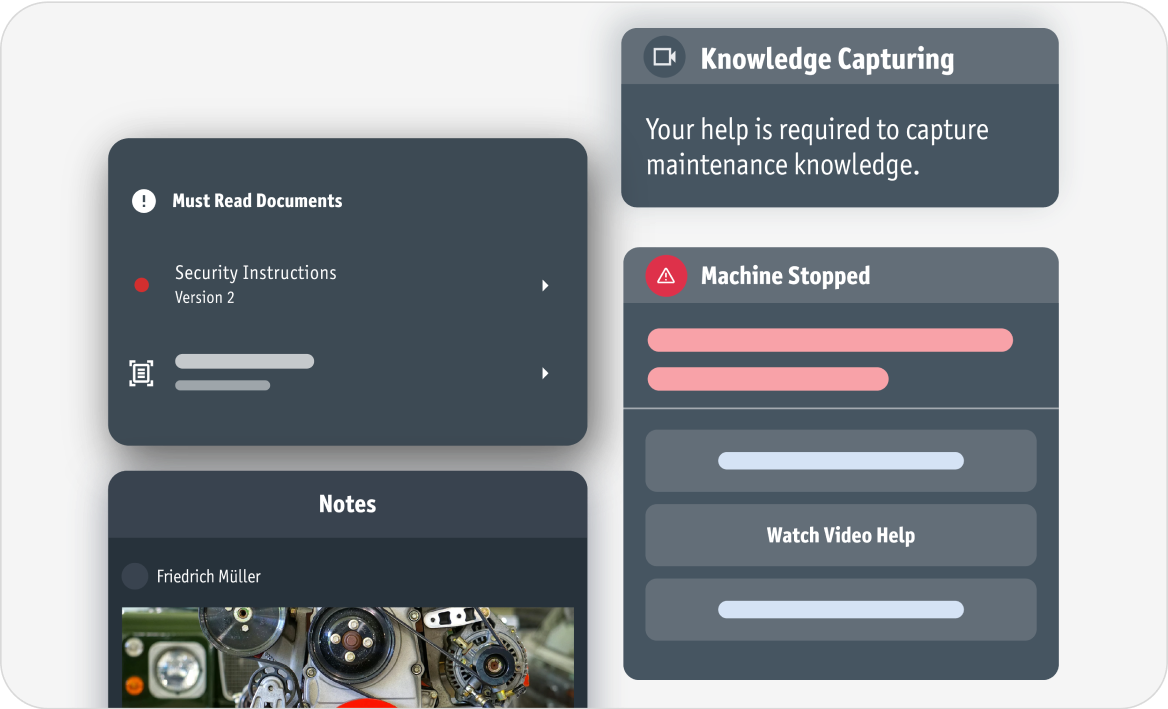

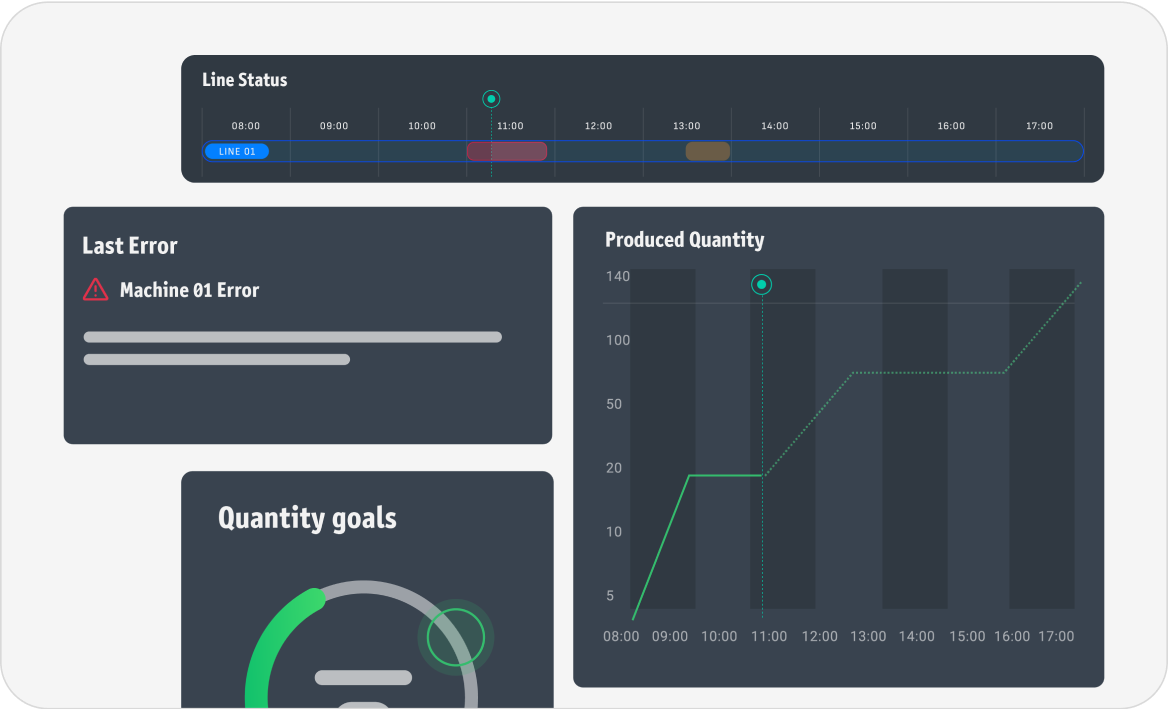

Empower Workers and Continuously Improve

- Provide frontline workers access to apps on any device

- Improve visibility and tracablility on all operations

- Easily iterate, deploy and scale what you build

You’re in good company!