How To Boost Andon Efficiency

Digitizing Andon Systems Made Simple

Workerbase’s Connected Worker platform presents a revolutionary approach for manufacturers aiming to modernize their Andon systems. This platform equips shop floor workers with advanced wearable tech and mobile apps, creating a harmonious blend with the manufacturing setting.

Streamlining the Shift to Advanced Andon Systems with Workerbase

Here’s how Workerbase simplifies the transition to a state-of-the-art Andon system:

Instant Data Access for Real-Time Action

- Workerbase enables your team to access vital performance metrics instantly. This feature ensures quick issue identification and resolution, boosting operational efficiency.

Smart, Automated Alerts

- With automatic alerts, Workerbase instantly informs the right people when specific thresholds are crossed, helping to address issues promptly and reduce operational interruptions.

Intelligent Task Routing

- The platform’s smart task escalation and delegation are based on location, skillset, and availability, ensuring that the right person handles each issue efficiently.

Seamless Remote Collaboration

- Workerbase promotes effective remote collaboration, allowing on-site personnel to receive immediate assistance from experts and supervisors, fostering a continuous improvement culture.

In-Depth Data Analytics

- Acting as a unified interface for your IT ecosystem, Workerbase consolidates data from diverse sources, enabling insightful analytics and data-driven decision-making to improve production and product quality.

The Workerbase platform is highly customizable, offering cloud or on-premise setups. It’s quick to deploy and supports various operating systems, ensuring it’s always with you, wherever you work.

Download the whitepaper to learn how you can transform your Andon with Workerbase!

A Glimpse into a Workerbase-Driven Digital Workflow

Here’s a typical digital workflow in a Workerbase-powered environment:

- Operators send requests to specific groups, like quality control or logistics, with customizable buttons.

- The system alerts the designated group, with re-alerts until someone accepts the task.

- Task execution is guided by step-by-step digital instructions.

- Management monitors production KPIs on a data dashboard for ongoing improvements.

Embracing the Future of Digital Andon in 2024

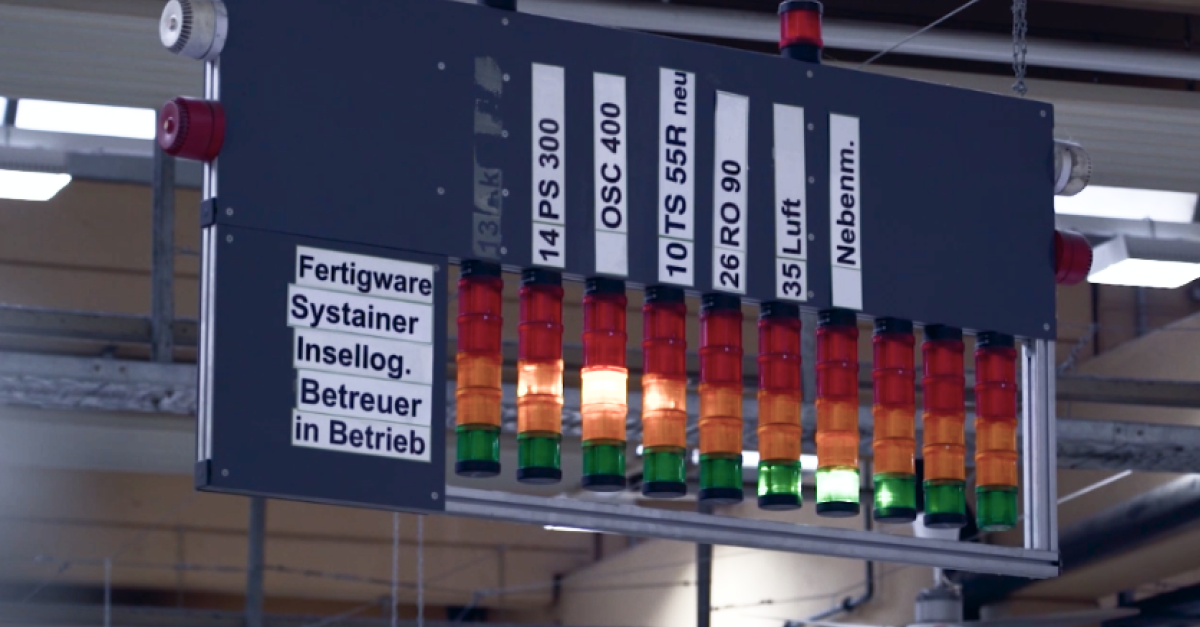

Originally a Toyota innovation, Andon has evolved significantly. Today, it’s not just a visual tool but a comprehensive system that flags problems promptly, ensuring production quality and safety.

In the current dynamic manufacturing landscape, transitioning to a digital Andon system is vital for staying competitive. Traditional methods, hindered by delayed information and limited data integration, are outdated. Modern factories require swift adaptation to changes and a data-driven approach, making digital Andon systems essential.

Digital Andon systems offer real-time visibility, system integration, and analytics, crucial for immediate decision-making and proactive issue resolution.

Workerbase: At the Forefront of Andon Modernization

Workerbase’s Connected Worker platform is at the forefront of this transformation. It empowers workers with wearable and mobile technologies, integrating flawlessly into the manufacturing process. Offering real-time monitoring, automated alerts, intelligent task management, remote collaboration, and analytics, it’s a comprehensive solution for manufacturers upgrading their Andon systems.