Increase operational efficiency, reduce bottlenecks and maximize output

You’re in good company!

Connected Worker Apps for Discrete Manufacturing

From minimizing downtime to optimizing changeovers, our Connected Worker apps empower your team with digital workflows that drive efficiency and eliminate operational disruptions.

Explore our Connected Worker apps for Discrete Manufacturing

Work Instructions

Changeover Management

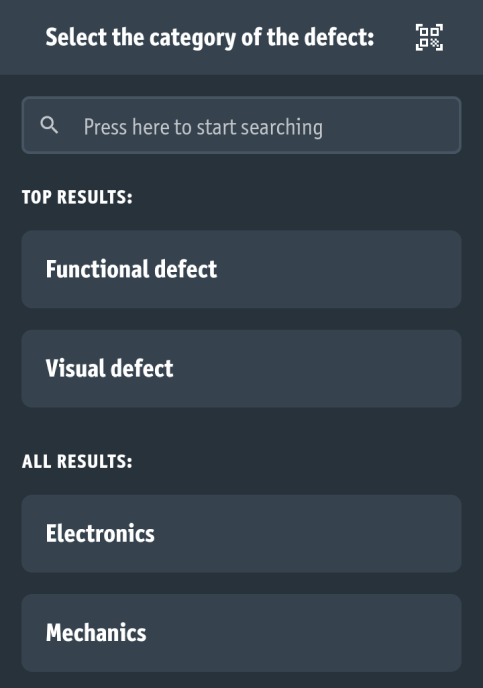

Quality Control

Machine Operation

Maintenance Assistance

Team Collaboration

Your factory. Without disruptions.

Increase throughput

Reduce quality costs

Improve productivity

Simplify complex assembly tasks

Discrete manufacturing often involves complex assembly processes that require precision and coordination. Workerbase’s digital workflows ensure accuracy and streamline assembly tasks, reducing errors and enhancing productivity in complex manufacturing environments.

Thrive in a dynamic market

The dynamic nature of the discrete manufacturing industry requires agility. Workerbase’s platform allows you to adjust production processes real-time, ensuring your organization can rapidly respond to changing market demands without compromising efficiency.

Platform functions for Discrete Manufacturing

Task automation

Automate routine tasks to boost efficiency and minimize manual effort in discrete manufacturing operations.

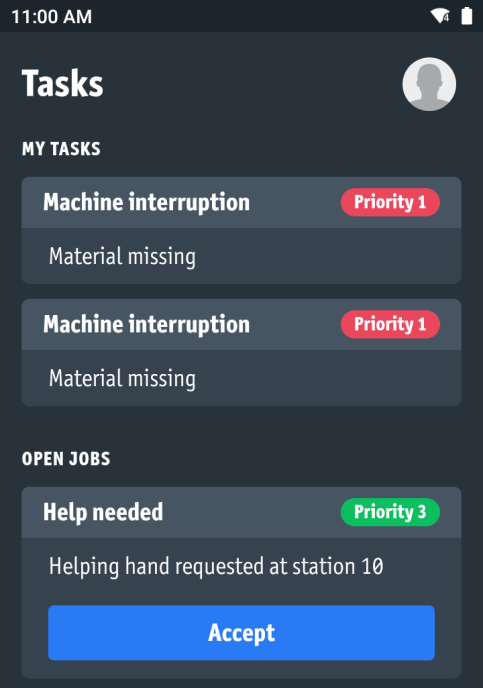

Task assignment

Automatically assign tasks based on skill levels and workload distribution to optimize resource utilization.

Alerts

Receive real-time alerts about unplanned machine downtimes for prompt response and issue resolution, preventing disruptions in discrete manufacturing.

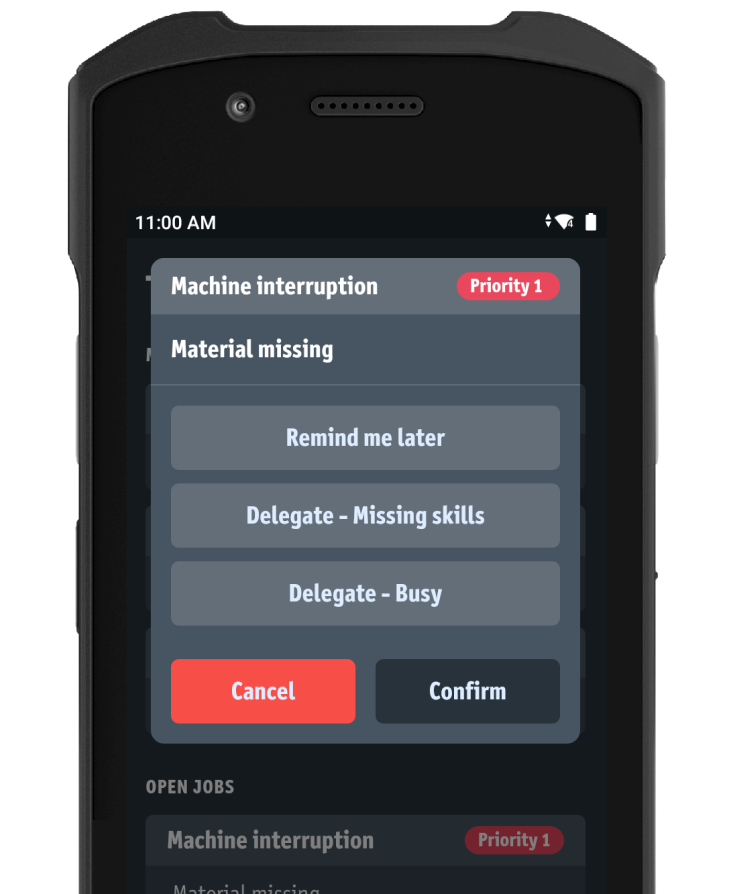

Escalation

Define escalation paths for urgent matters to ensure rapid resolution through the appropriate channels.

Delegation

Seamlessly delegate tasks to maintain continuity during shift changes or absences in discrete manufacturing.

Team coordination

Facilitate real-time communication and collaboration among team members to optimize teamwork in discrete manufacturing.

Enhance team performance

Get in touch with us

Ready to dive into Workerbase’s Connected Worker platform? Receive a personalized demo tailored to your challenges. Schedule a call now!

- Connect workers with industrial grade smart devices

- Integrate your ERP and MES systems for a holistic view

- Track progress and visualize work as it happens