Machine Info

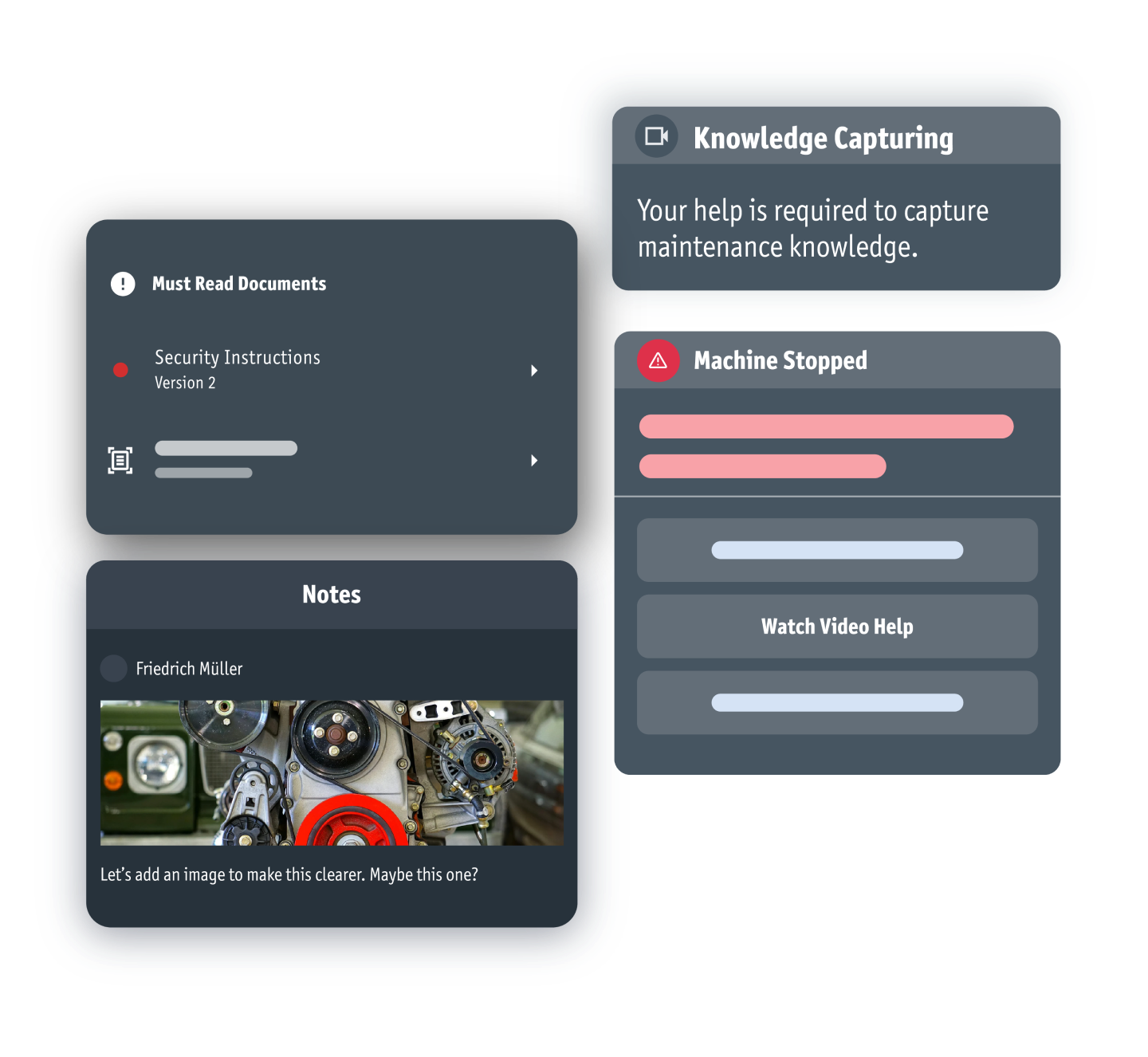

Provide your frontline workers access to all relevant machine data, like real time status, documentation and historical data. Assign tasks to workers and run regular procedures like forms and checklists.

Providing information as and when needed, makes a significant impact

Increased Throughput

Give operators instant access to machine insights—fewer interruptions, faster reactions, and more output from every shift.

Decreased MTTR

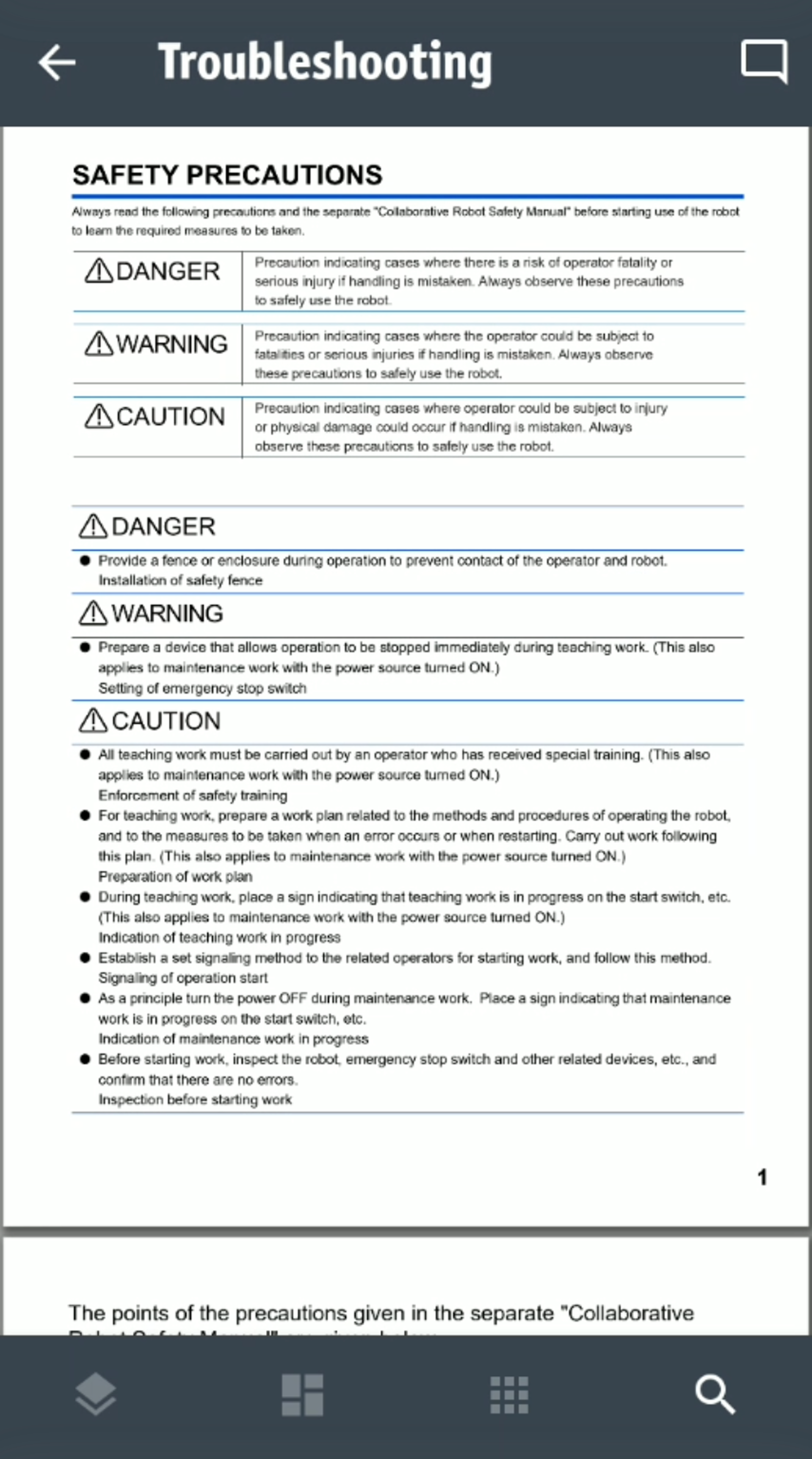

Accelerate issue resolution with real-time alerts, clear responsibilities, and instant access to the right information—so machines get back up faster.

Increased Compliance Rate

Standardize machine-related procedures and make the right documentation accessible—ensuring every action is done by the book, every time.

Why use the Machine Info App?

How our Machine Info App streamlines your manufacturing operations

Existing Processes

- Lack of accurate and real-time machine data leading to unplanned downtimes

- Time consuming to search or update machine related documents

- Lack of centralized system or single source of truth

With Workerbase

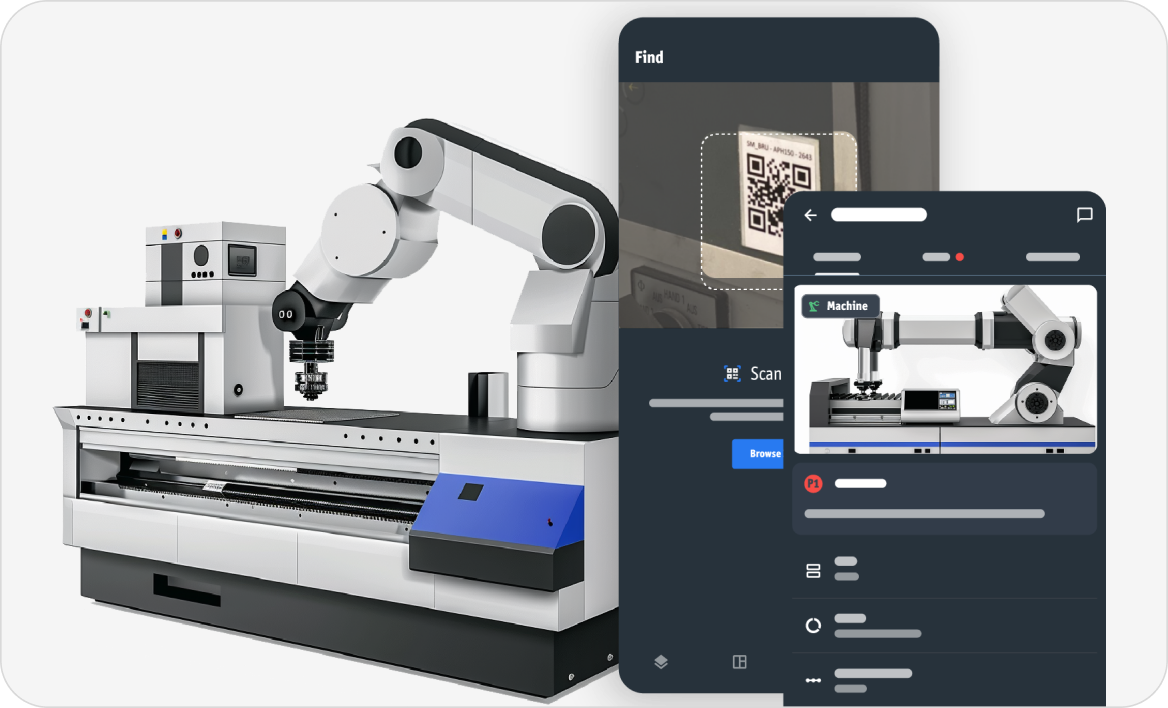

- Latest machine data available with the scan of a QR code

- All documents digitally attached to the machine and available where needed

- Digital twin of the machine with all latest information and documents attached

Easy steps to implement machine info

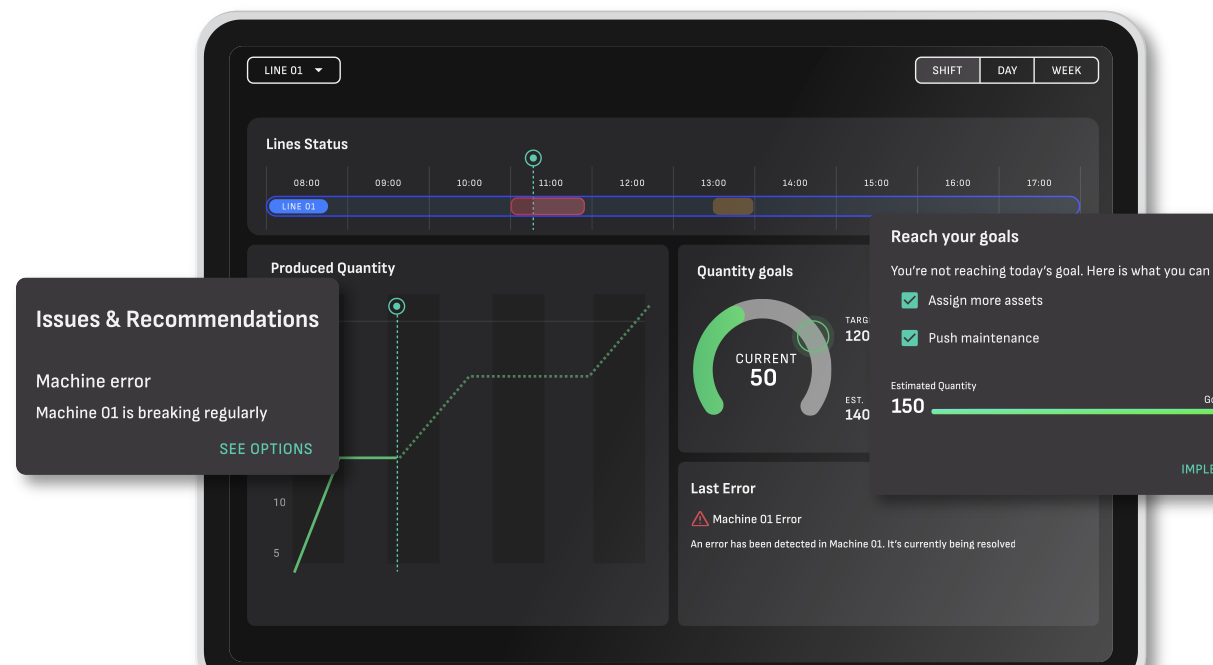

Configure and customize your display

Select which information to display in the app—error codes, machine IDs, sensor values, and more.

Allow workers to add best practice documents right from the field. Optionally enable our AI Troubleshooting Agent and provide your workers with recommendations based on historical data.

Discover Why Industry Leaders Use Workerbase

We’d love to walk you through how our platform can solve your specific manufacturing and production challenges and deliver measurable results.

We’d also be happy to share more insights on how our platform tackles challenges such as:

- Information access and task related support for frontline workers

- Inflexible and siloed IT infrastructure, such as existing MES or ERPs

- Achieving data maturity from your entire manufacturing ecosystem