SMT Changeover

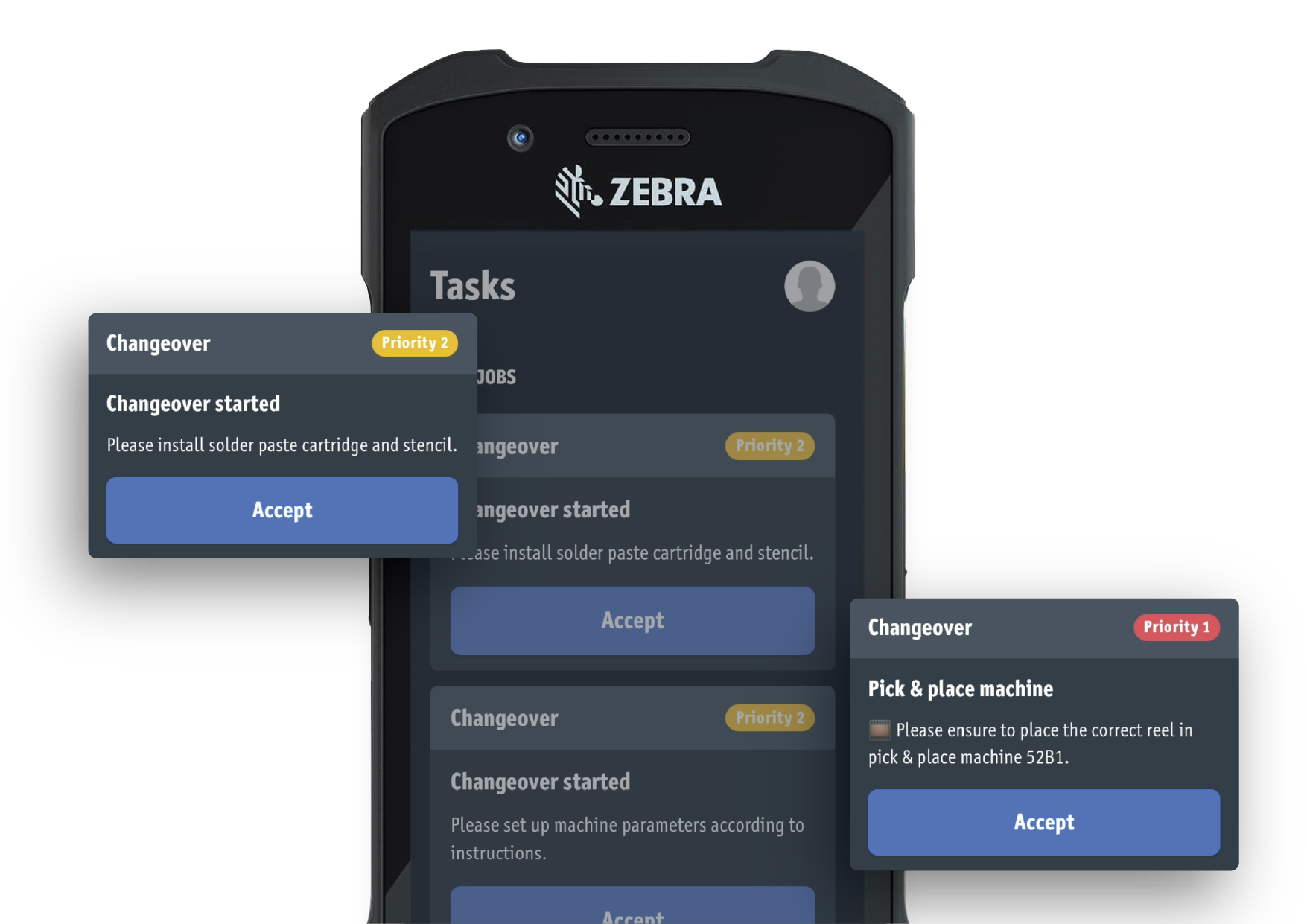

When changeover processes for SMT lines run at high efficiency, all steps of changing the line are efficiently coordinated and distributed to the correct experts at the right moment in time.

Workerbase ensures efficient changeovers and additionally eliminates unnecessary waiting times because of missing components or mix up of changeover sequences. Moisture sensitive components are delivered just in time in order to maximize their floor lifetime.

Workerbase ensures efficient changeovers and additionally eliminates unnecessary waiting times because of missing components or mix up of changeover sequences. Moisture sensitive components are delivered just in time in order to maximize their floor lifetime.

Boost Efficiency With Faster Changeovers, Fewer Errors, Longer Component Life

Faster Changeovers

Reduction of changeover times by up to 20%

Error-Free Placement

Prevention of placement errors

Extend MSL Lifespan

Prolongment of MSL component lifetimes

Run SMT changeover processes with no delays

Existing Processes

- Planned Changeover times not met because of unforeseen issues.

- Delay in changeover because of missing or wrong reels

- Floor lifetime of moisture sensitive components exceeded because of changeover delays

With Workerbase

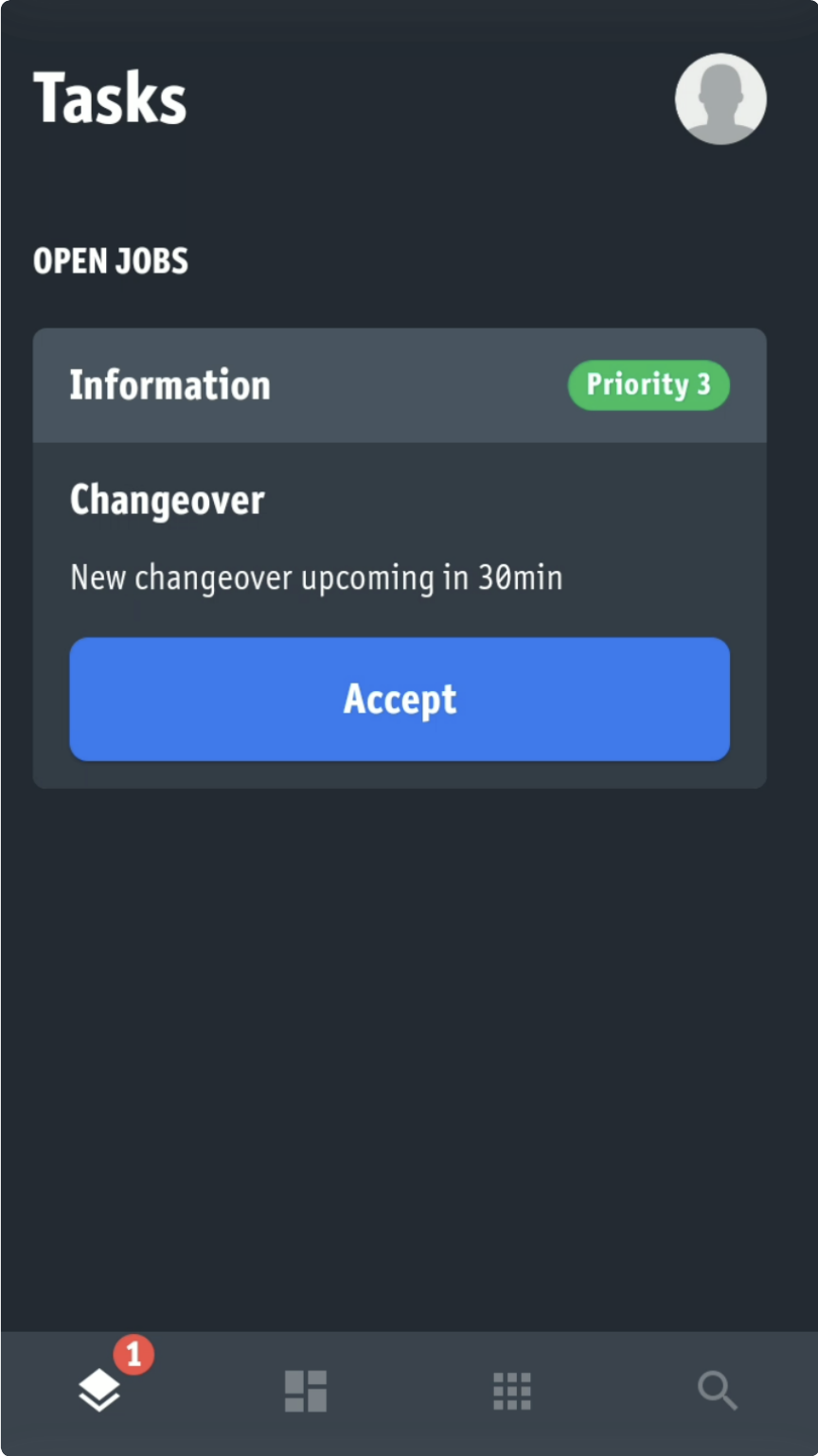

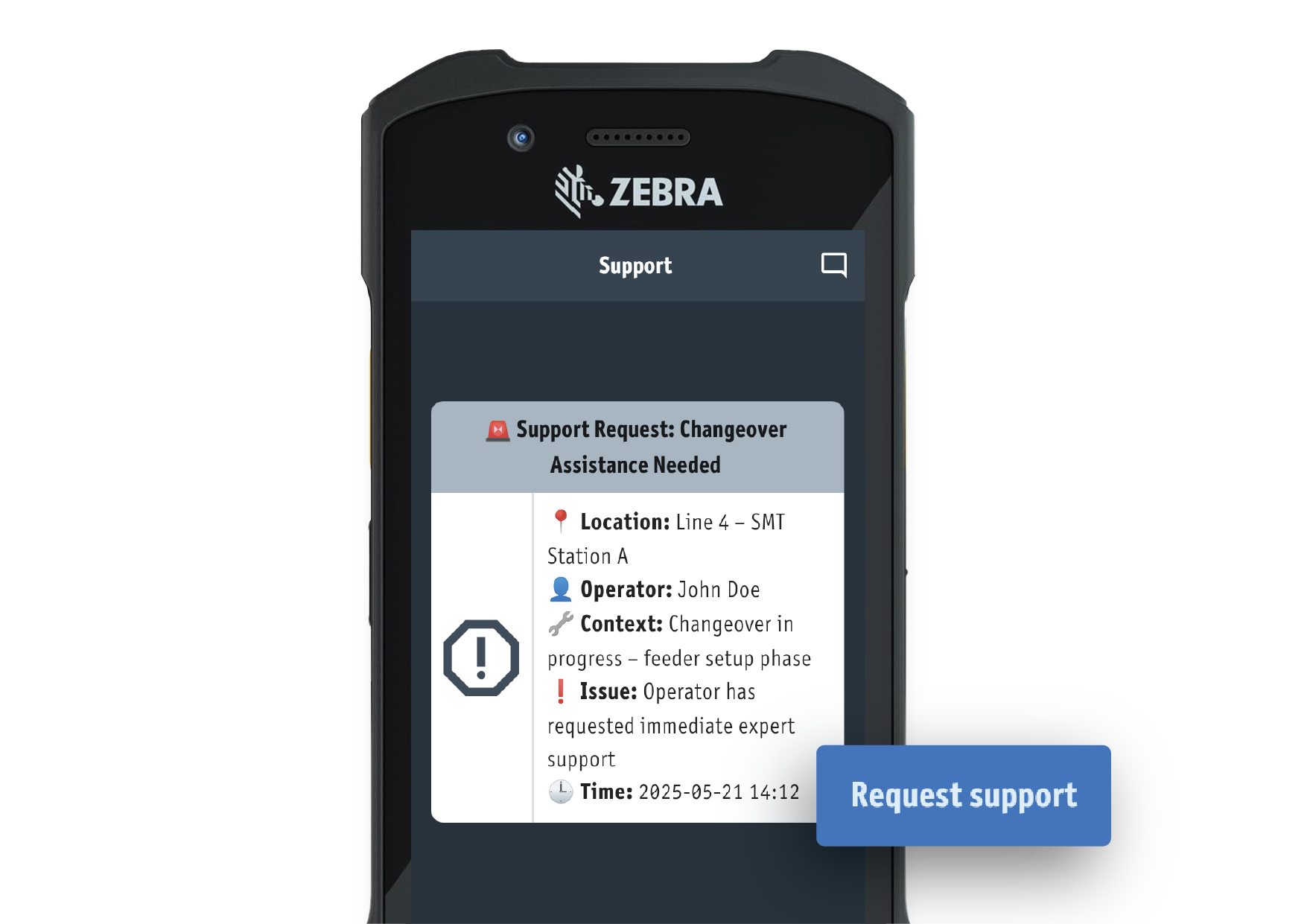

- Optimal flow of changeover process with no delays due to real-time coordination

- Prevention of delivery of wrong components with digital changeover instructions

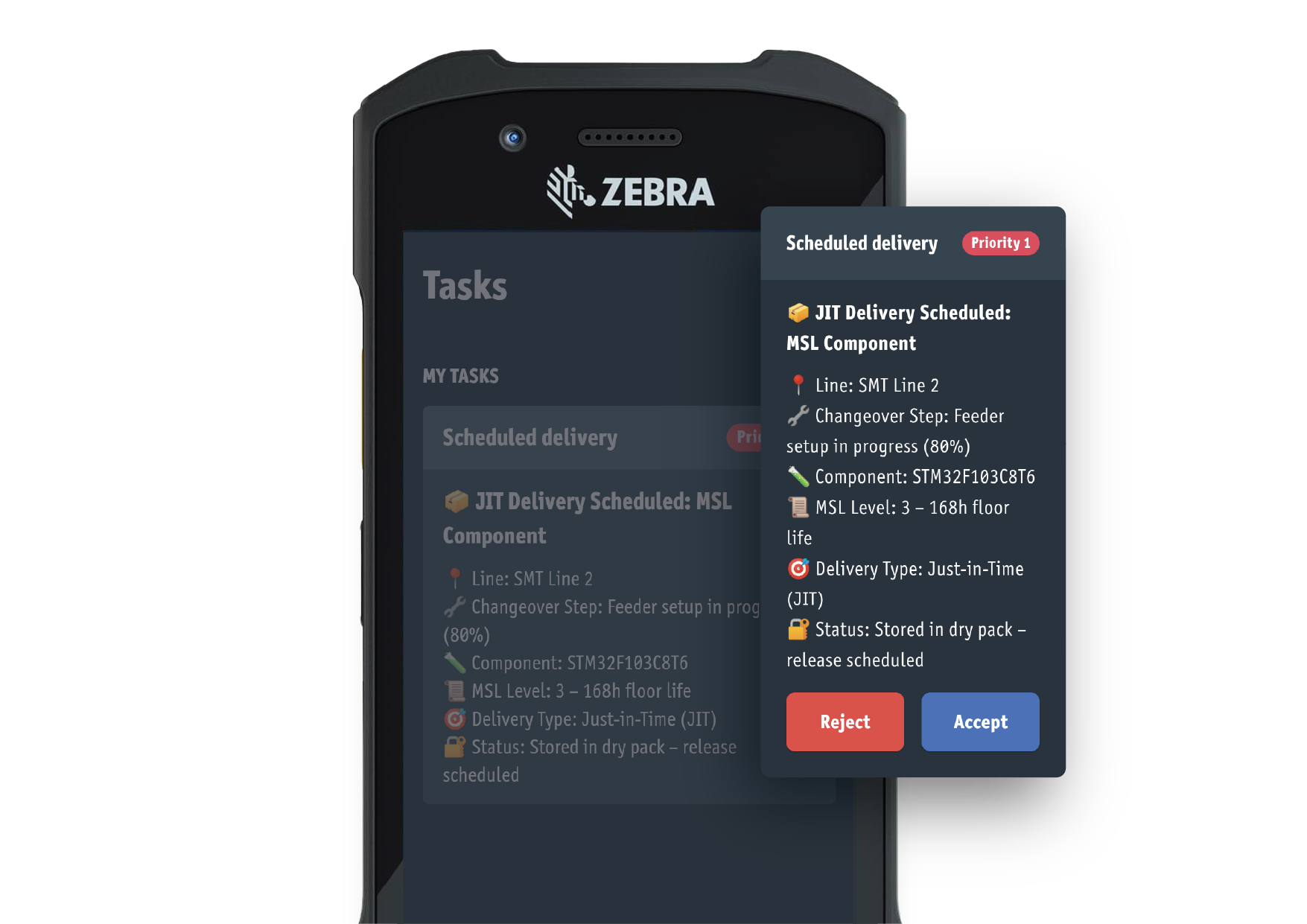

- Just in time delivery of MSL components according to real-time changeover progress

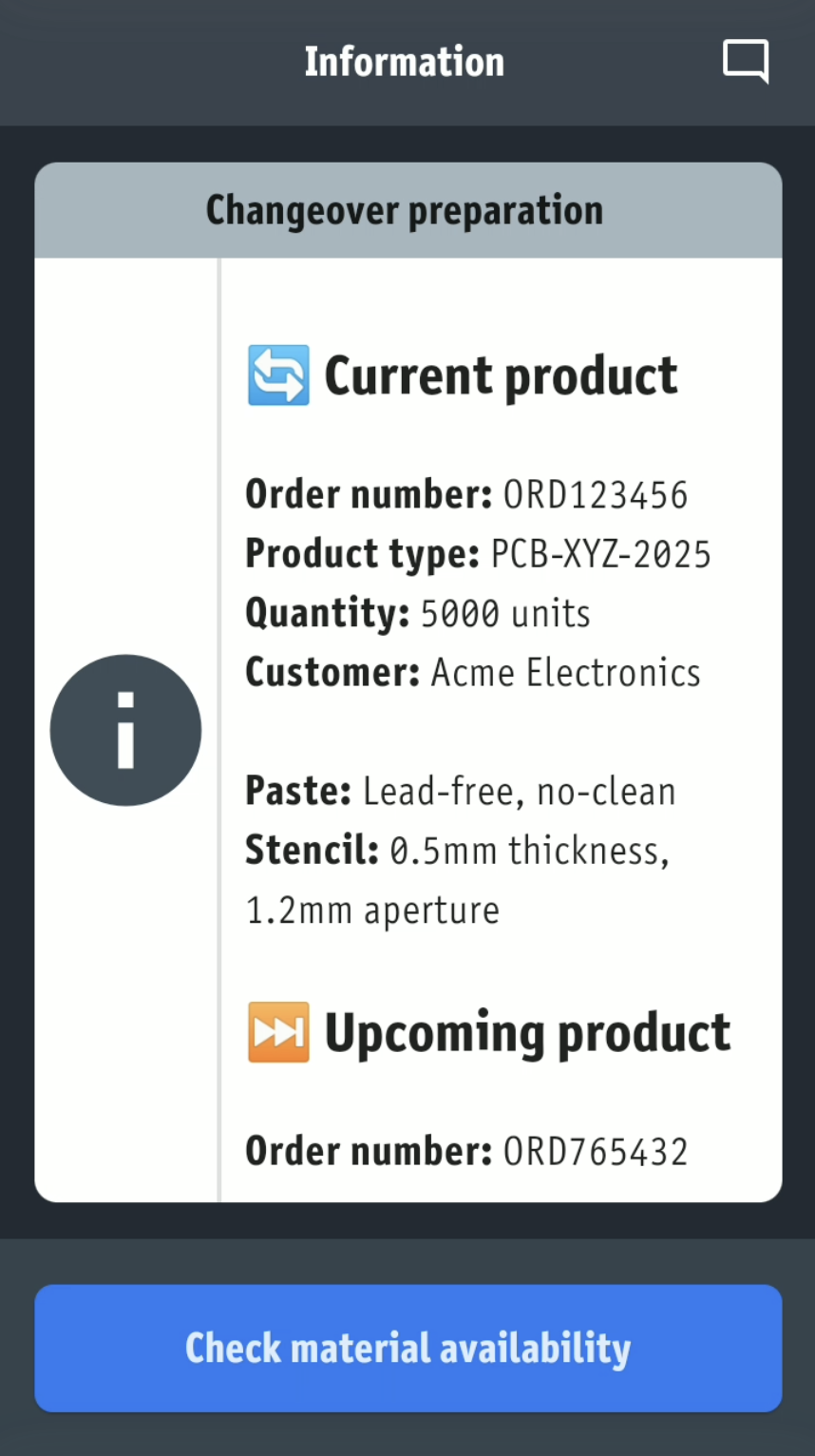

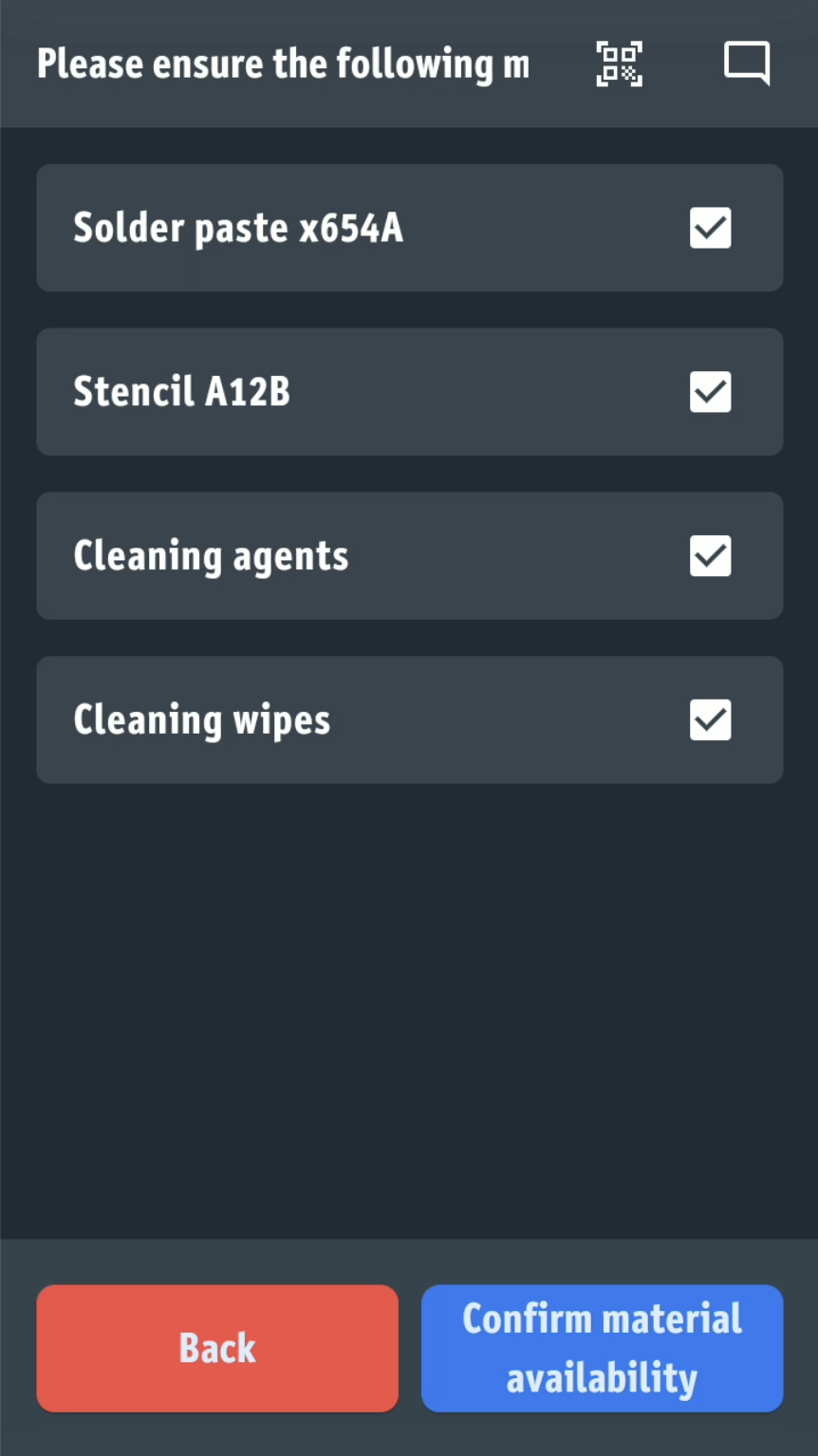

Digital work instructions to reduce mistakes

Digital work instructions for each step ensure that work is performed correctly. Digital checklists and barcode scans are introduced at critical process steps. Work instructions can be recorded as videos and will be automatically converted into step by step instructions using the Workerbase AI.

Discover Why Industry Leaders Use Workerbase

We’d love to walk you through how our platform can solve your specific manufacturing and production challenges and deliver measurable results.

We’d also be happy to share more insights on how our platform tackles challenges such as:

- Information access and task related support for frontline workers

- Inflexible and siloed IT infrastructure, such as existing MES or ERPs

- Achieving data maturity from your entire manufacturing ecosystem