SMT/THT Production Control

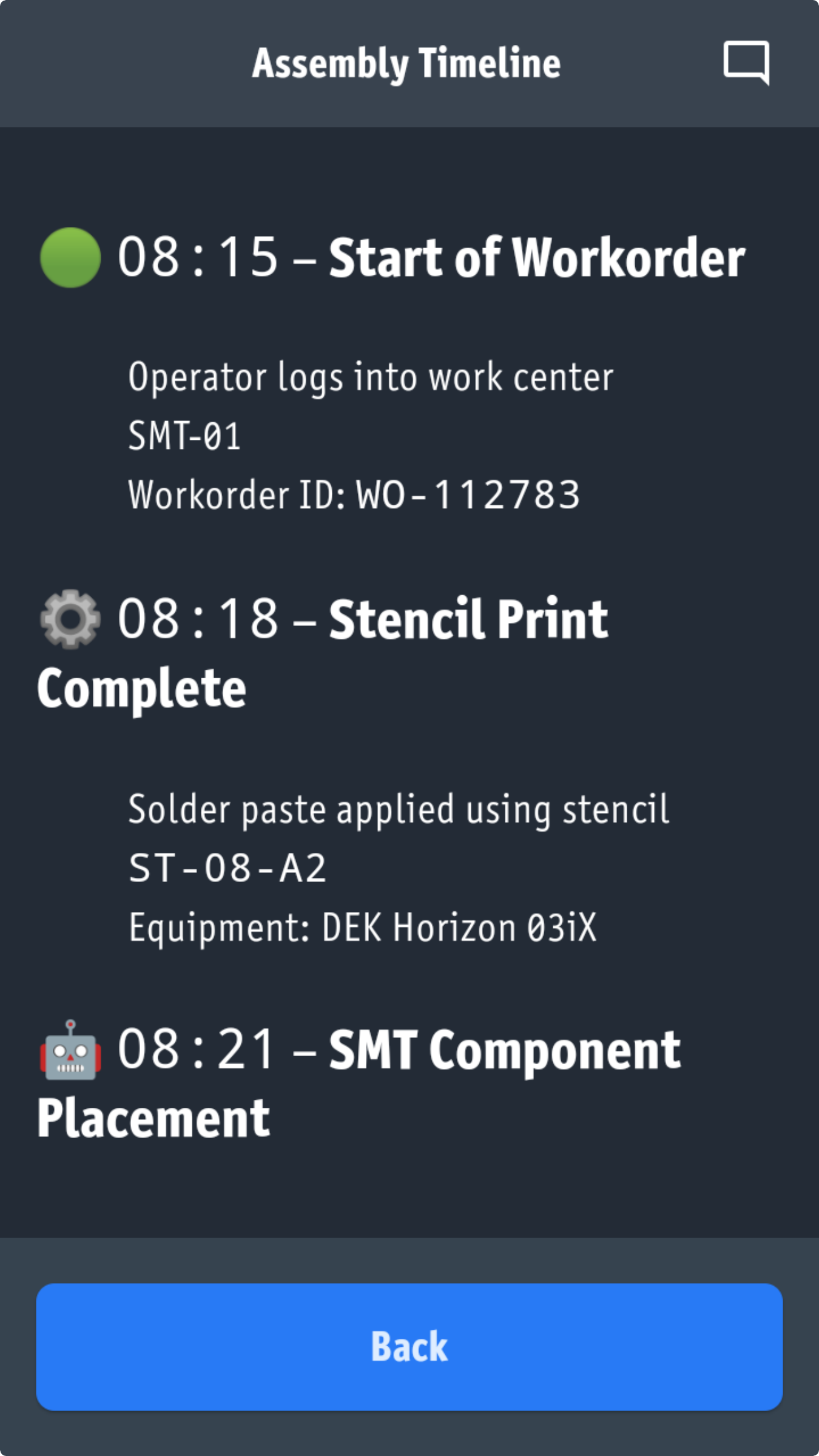

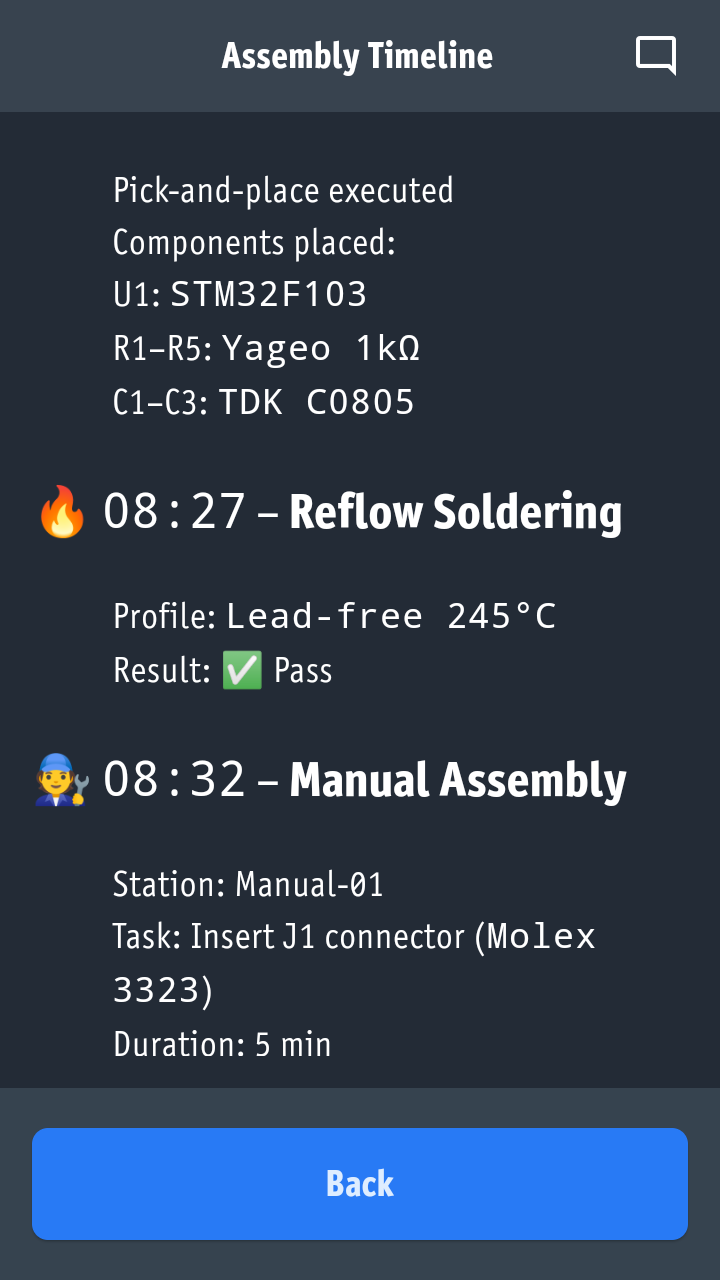

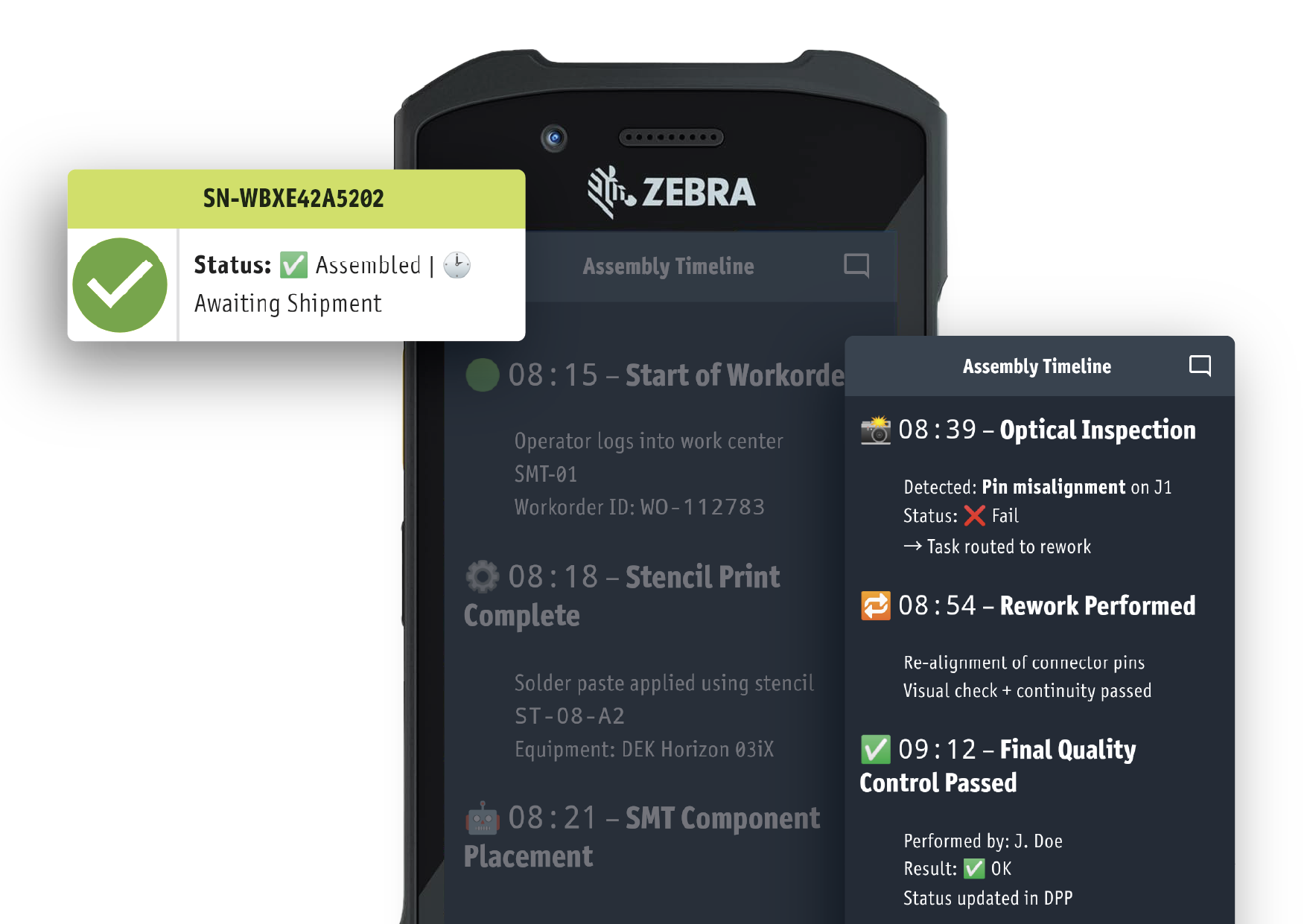

Give your frontline workers access to all required information during the SMT and THT production process. From placement to soldering, to quality control and rework.

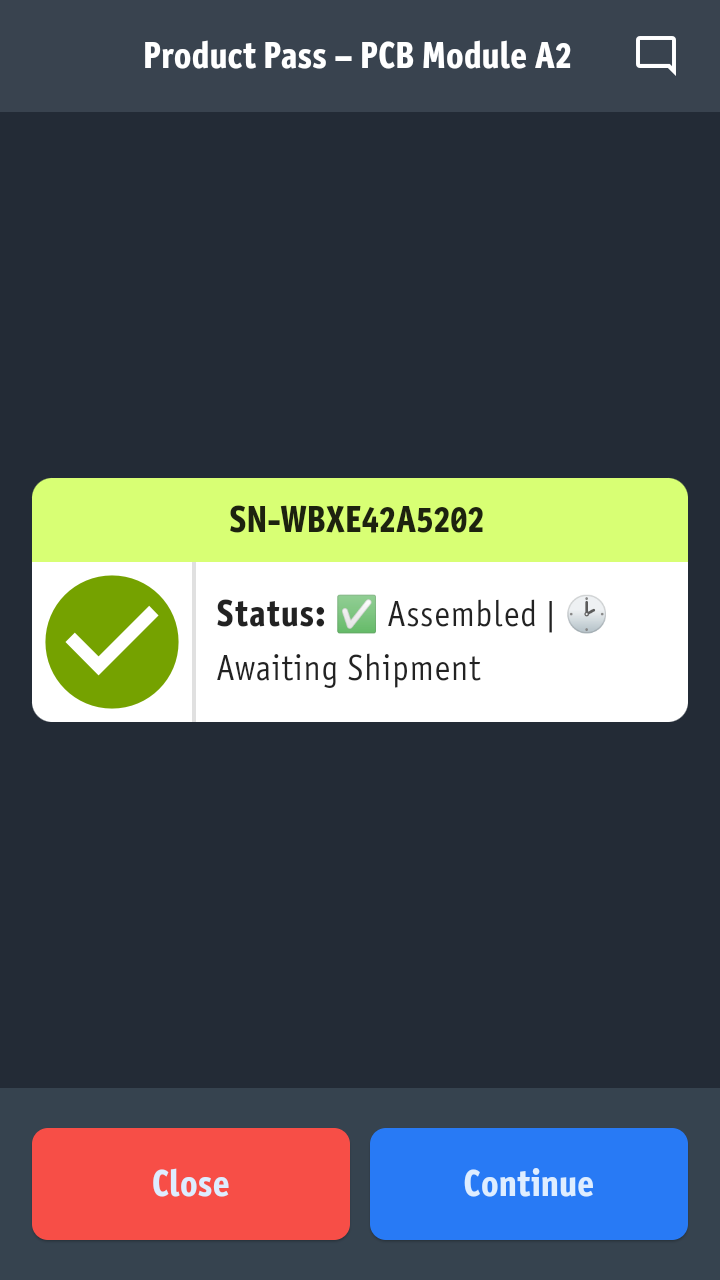

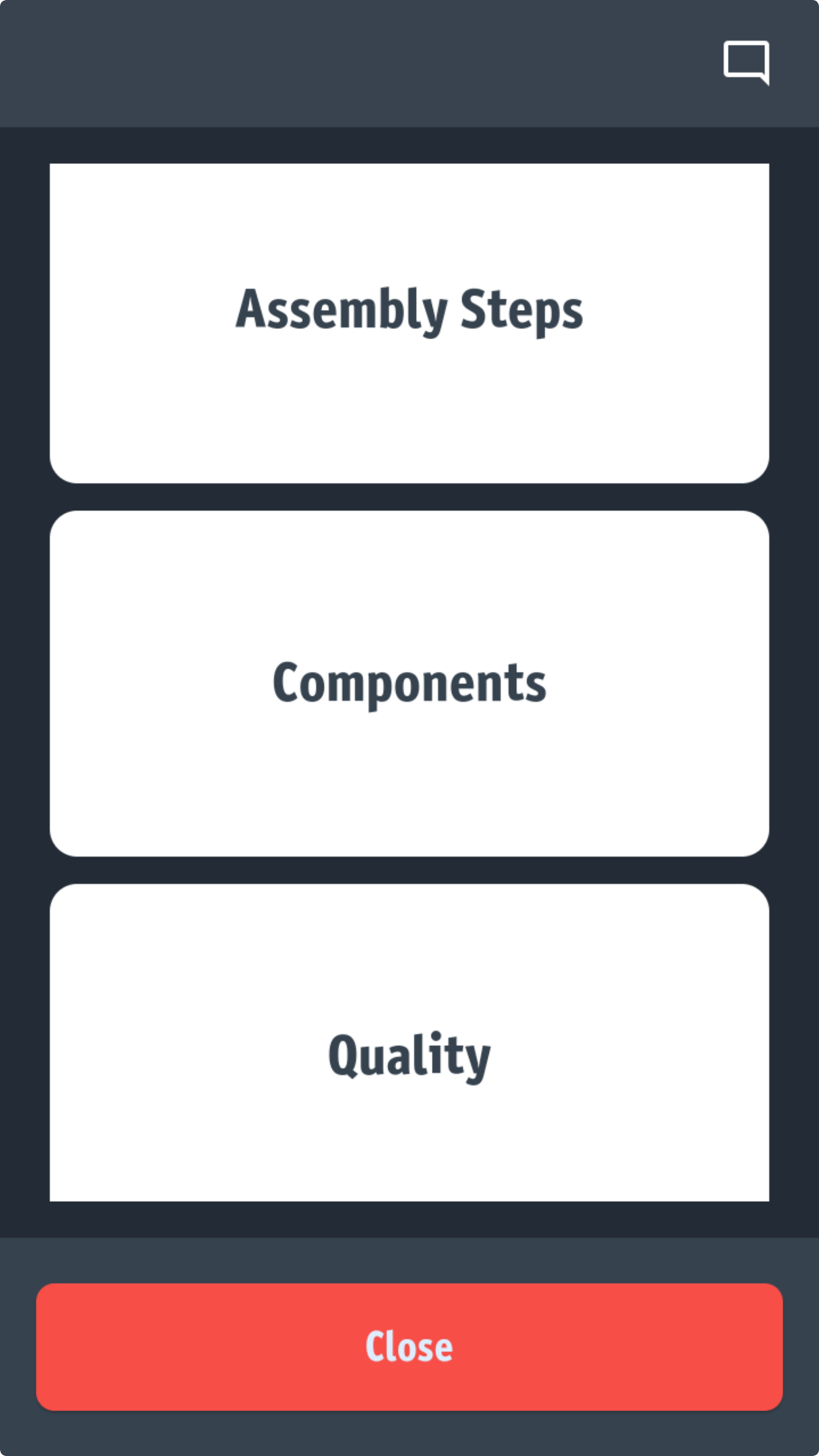

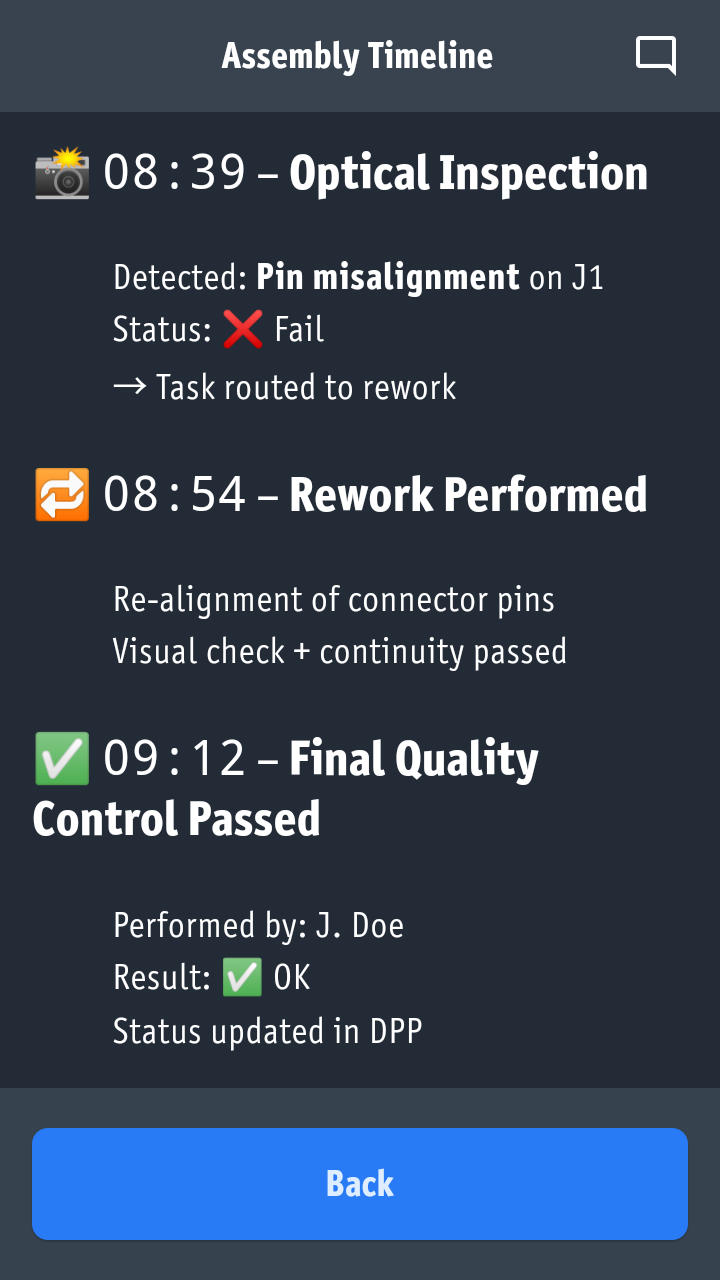

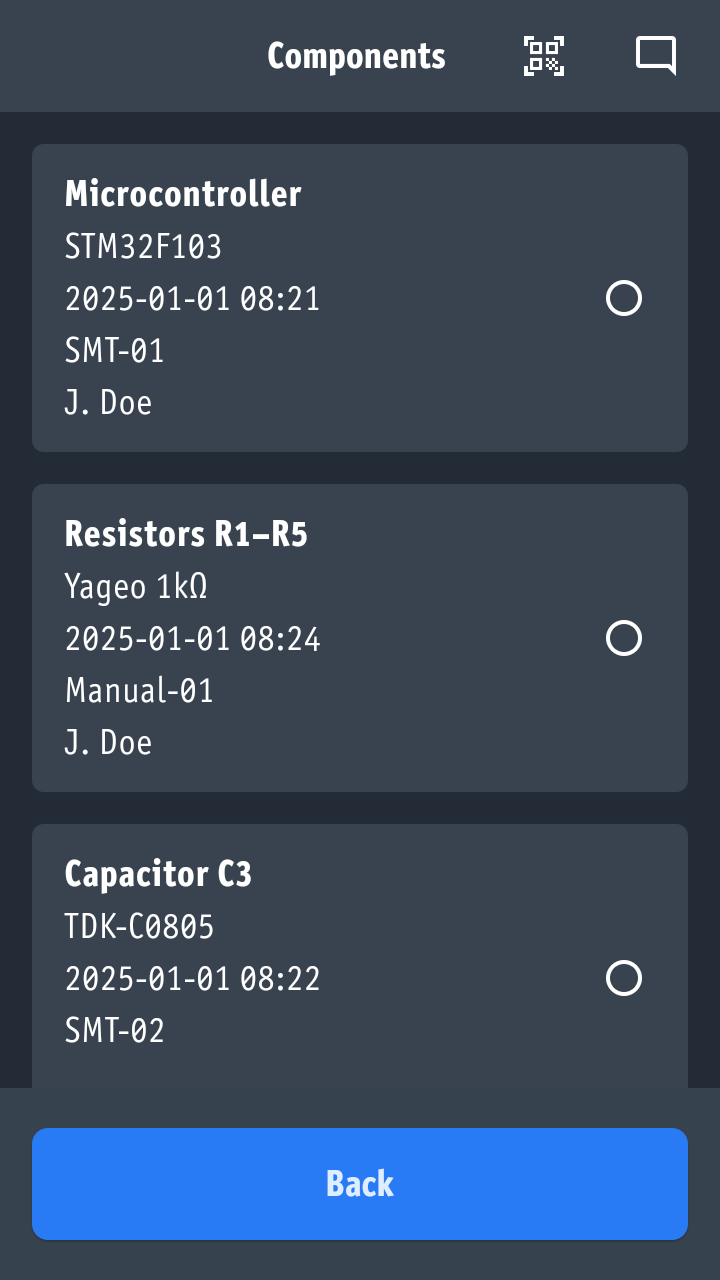

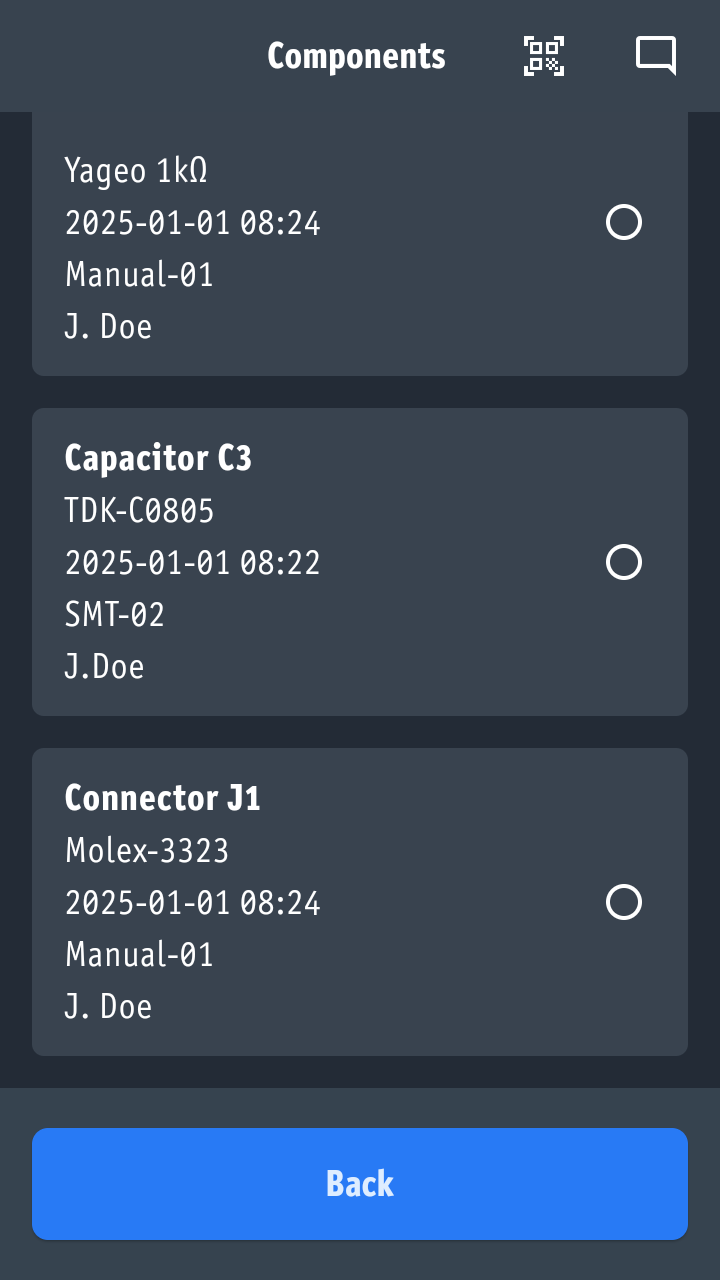

Access product specs and design documents and drill down into every component’s details from the BOM list, sorted by placement type. Mark items with defects and get full transparency on parts planned, parts produced and yield rates.

Access product specs and design documents and drill down into every component’s details from the BOM list, sorted by placement type. Mark items with defects and get full transparency on parts planned, parts produced and yield rates.

Accurate Sampling & Error-Free Production With Better SMT/THT Production Control

Prevent Errors

Prevent human error during the production process

Guarantee Consistent Quality

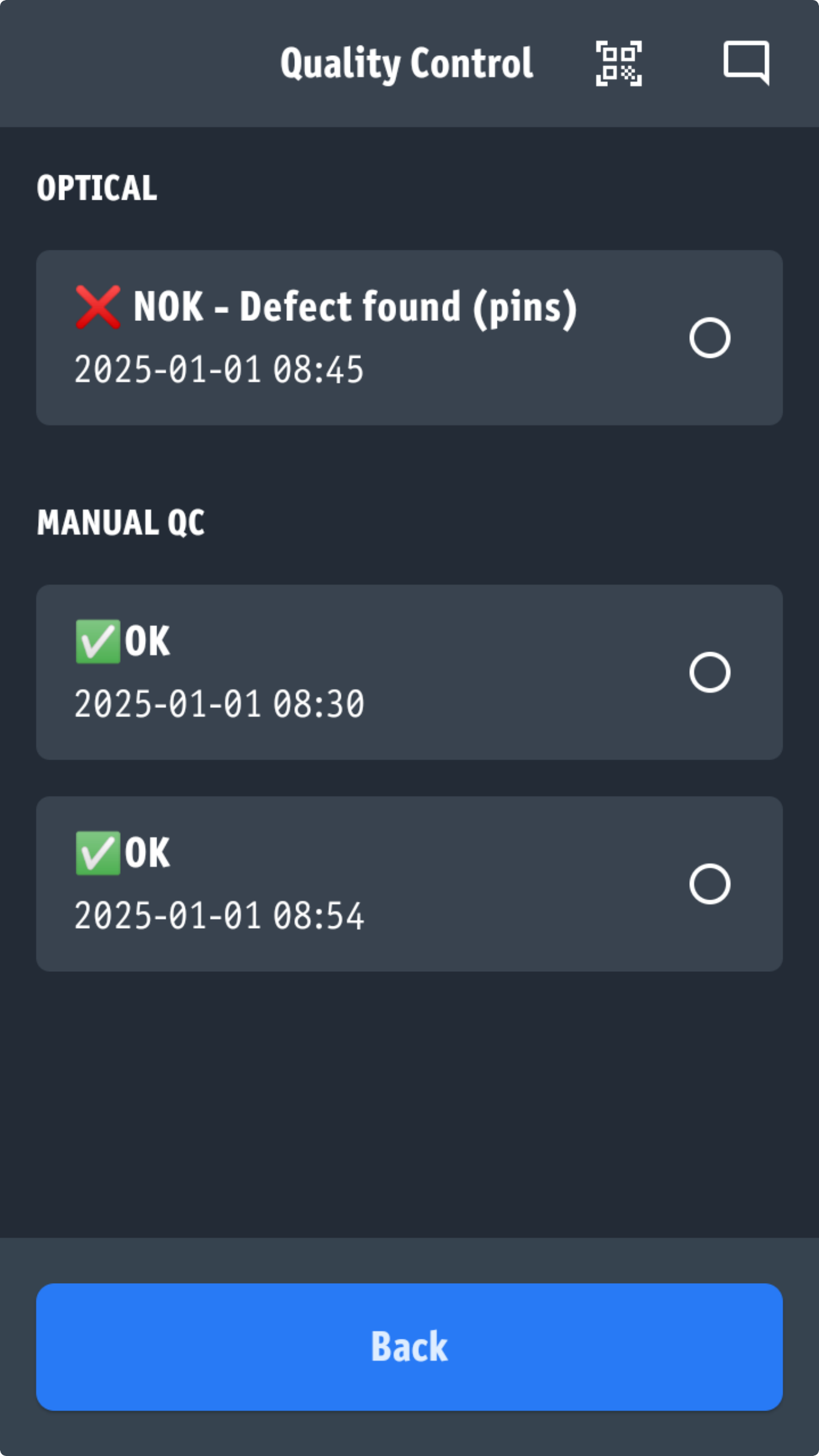

Ensure quality samples are taken at the correct intervals

Digital production control prevents human error

Existing Processes

- Frontline workers searching for information in paper binders, spec sheets and disparate systems

- Components mixed up because of small variances

- Handling instructions and floor lifetime not transparent

- Slow detection of mistakes because samples for quality assurance are taken randomly

With Workerbase

- All information in one system allows you to drill down into all aspects. All component specs available with 1 click

- Alerting of workers on components easily mixed up. All reel information stored with actual pictures to prevent mistakes

- Floor lifetime tracking of moisture sensitive components with alarms on expiry times

- Samples are taken at predefined intervals (fixed or increasing) ensuring no issues go undetected for too long

Discover Why Industry Leaders Use Workerbase

We’d love to walk you through how our platform can solve your specific manufacturing and production challenges and deliver measurable results.

We’d also be happy to share more insights on how our platform tackles challenges such as:

- Information access and task related support for frontline workers

- Inflexible and siloed IT infrastructure, such as existing MES or ERPs

- Achieving data maturity from your entire manufacturing ecosystem