SMT/THT Quality Control

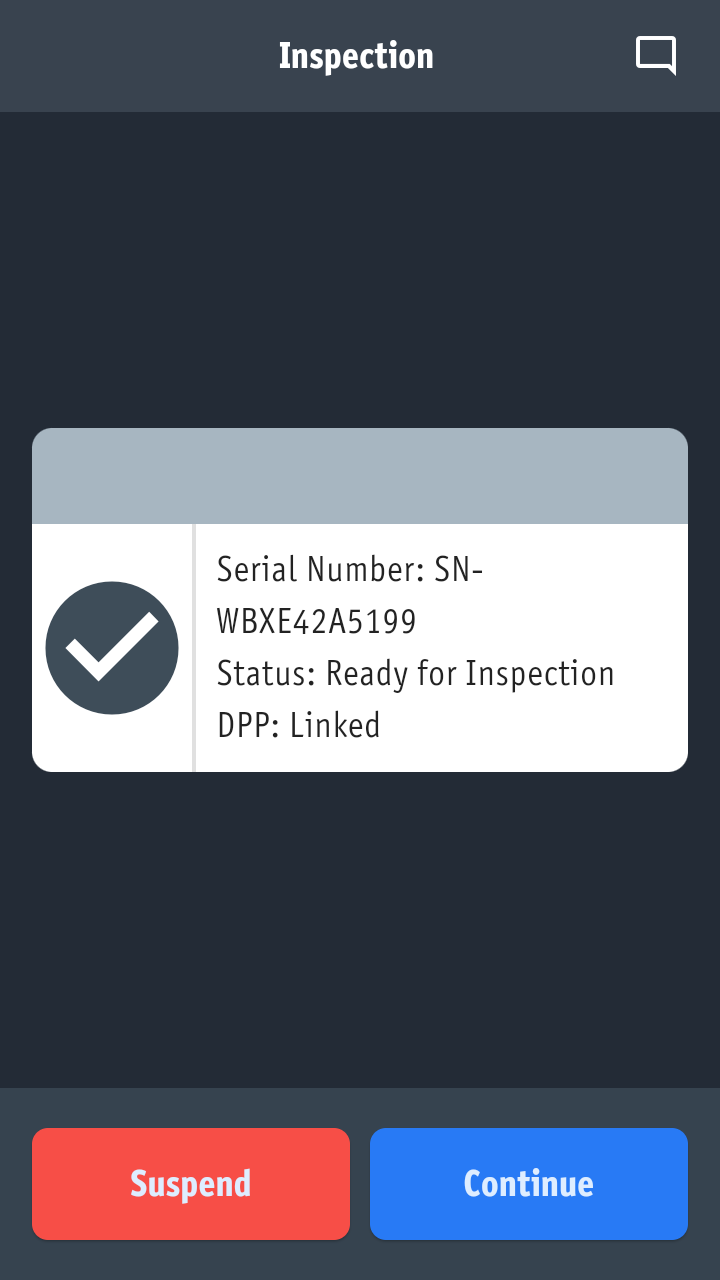

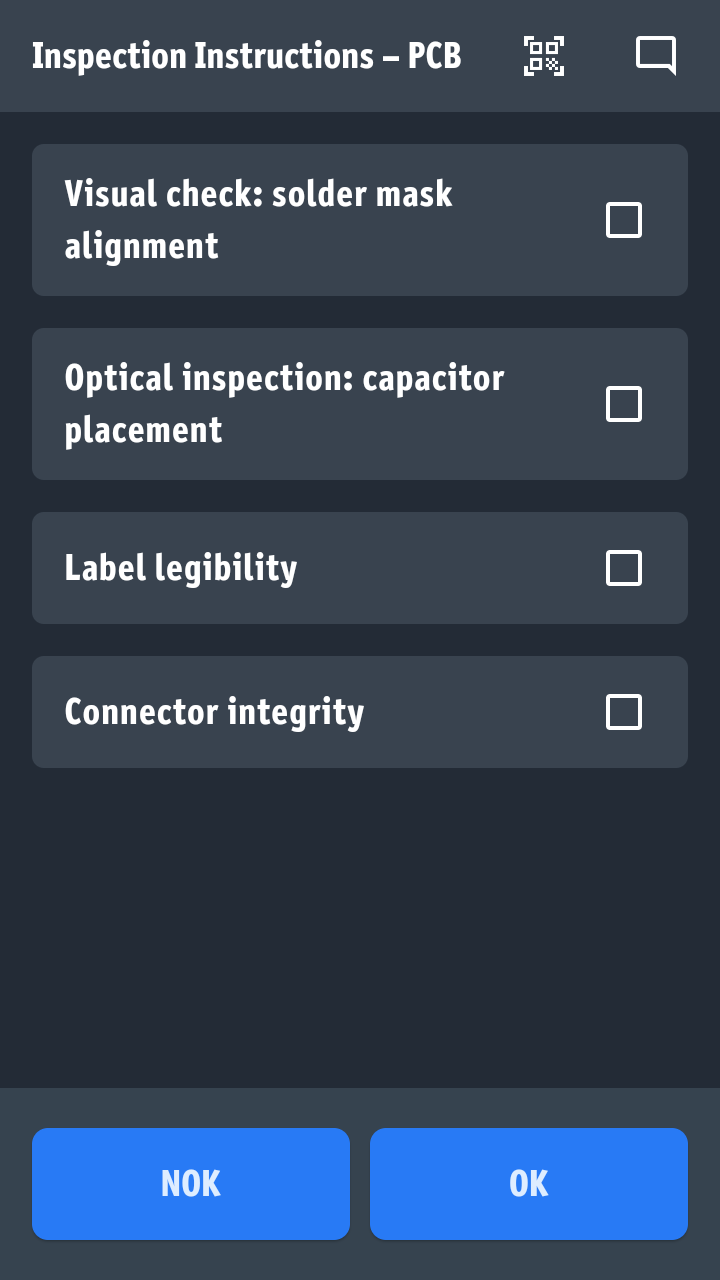

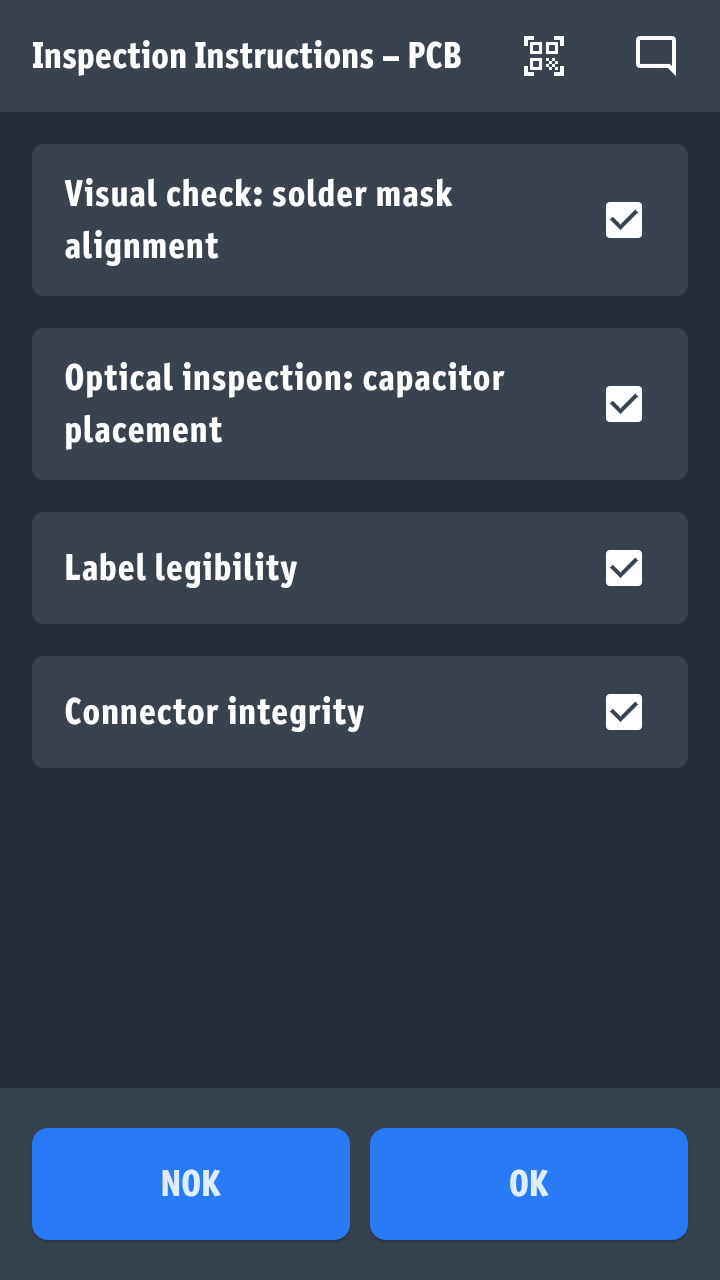

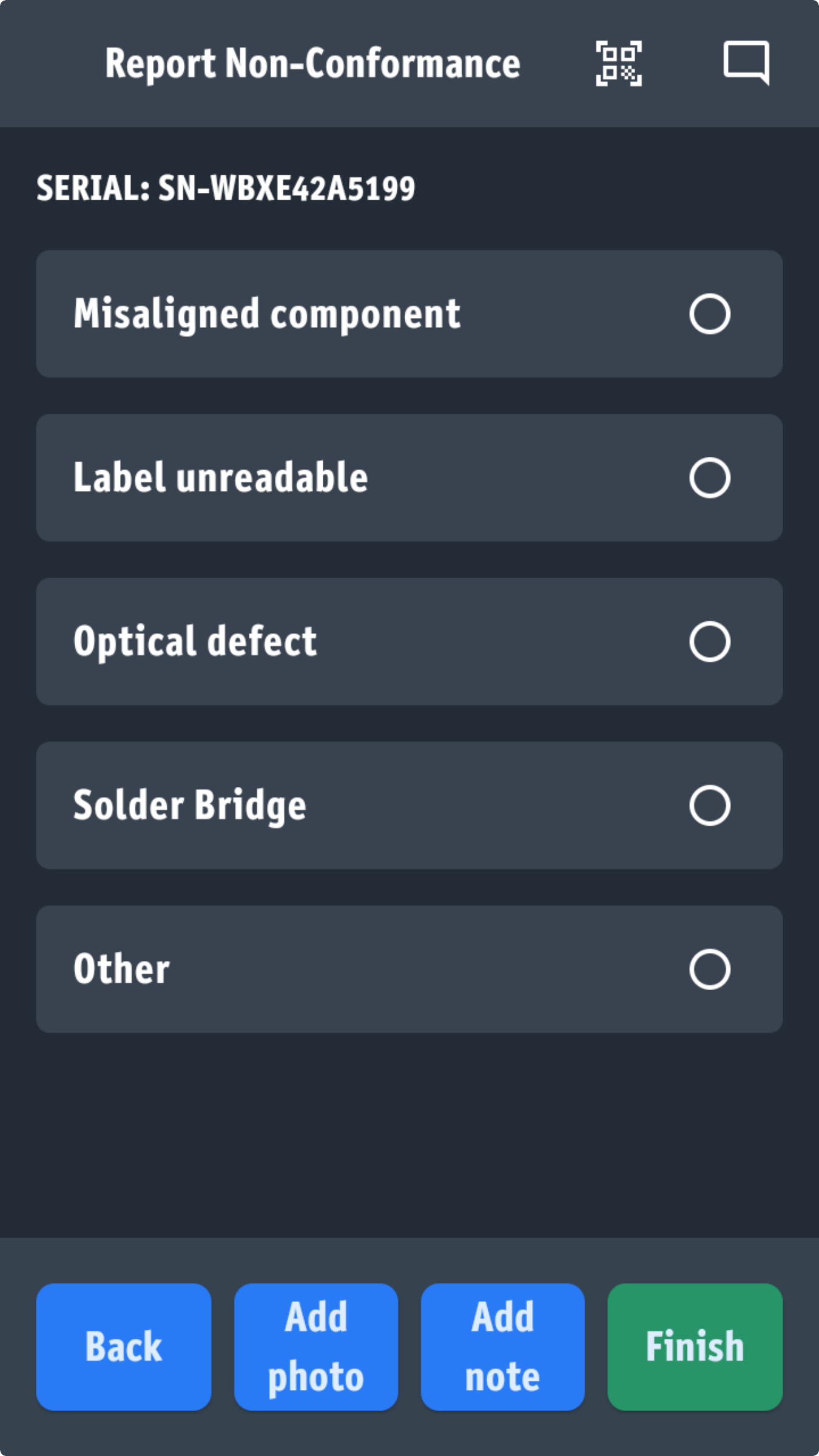

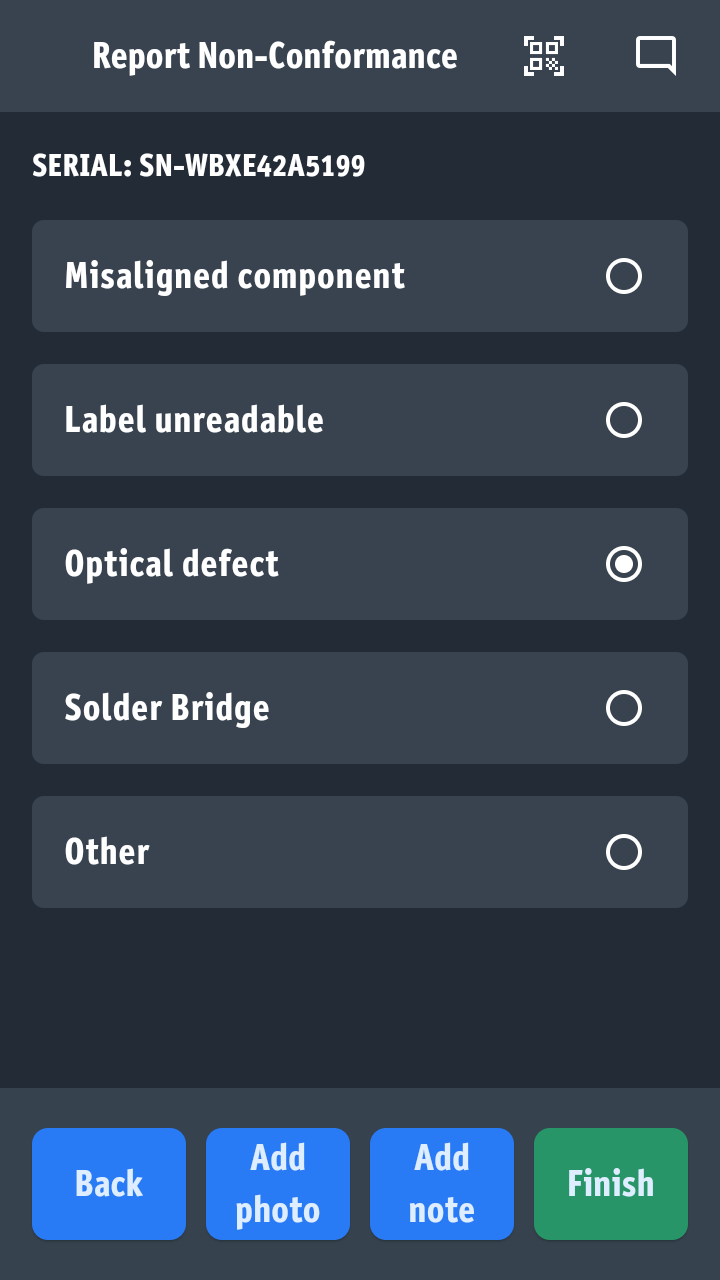

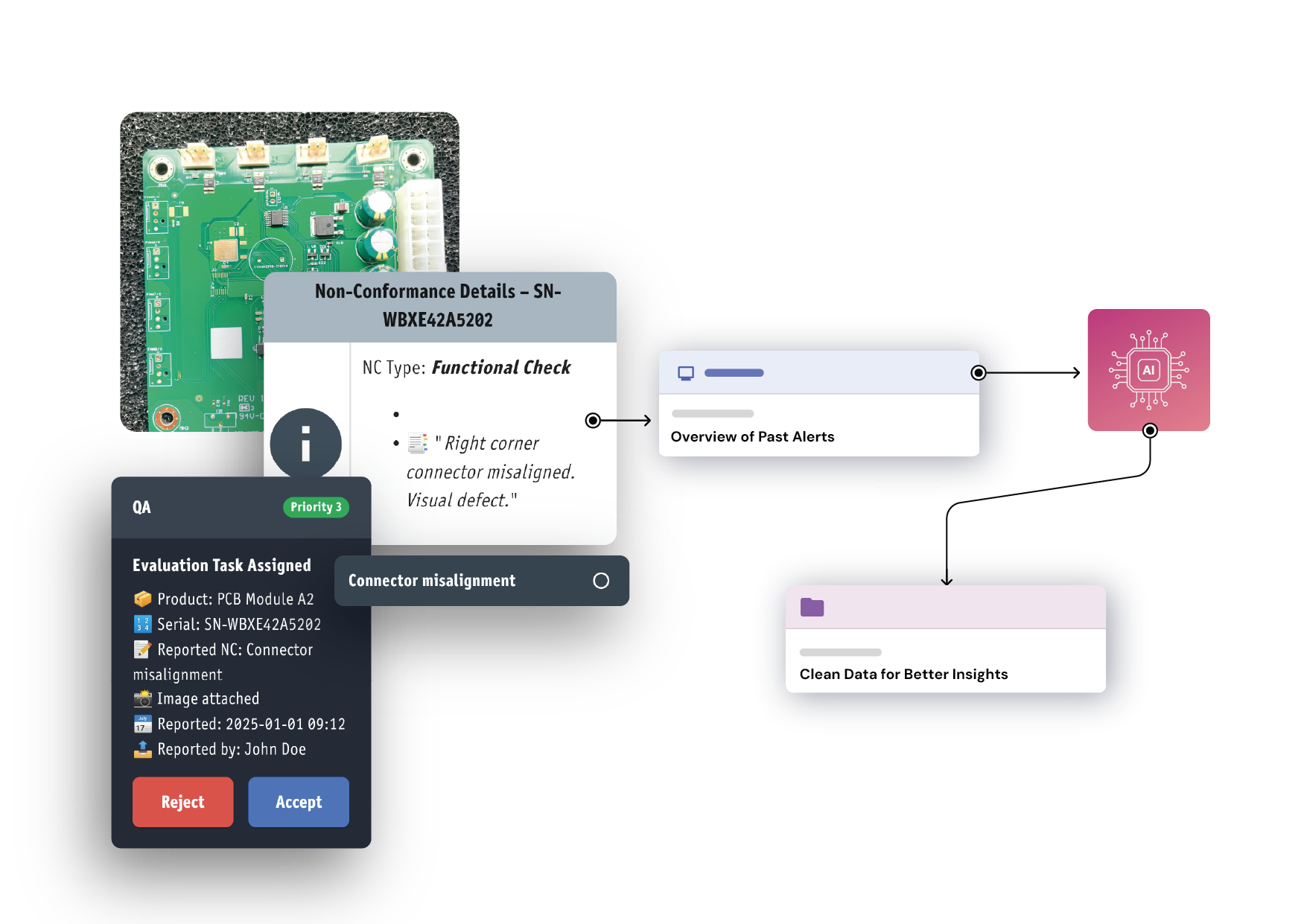

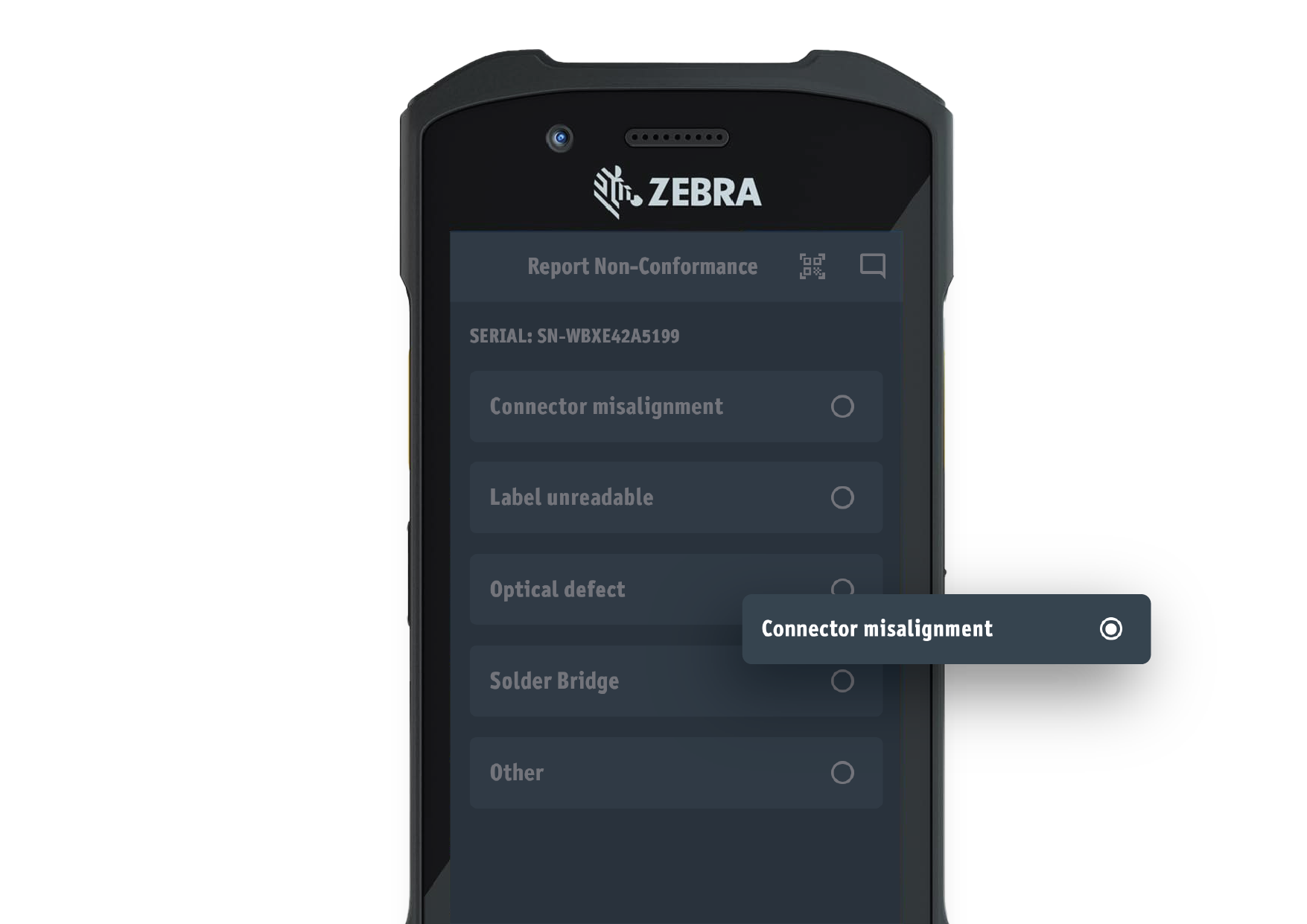

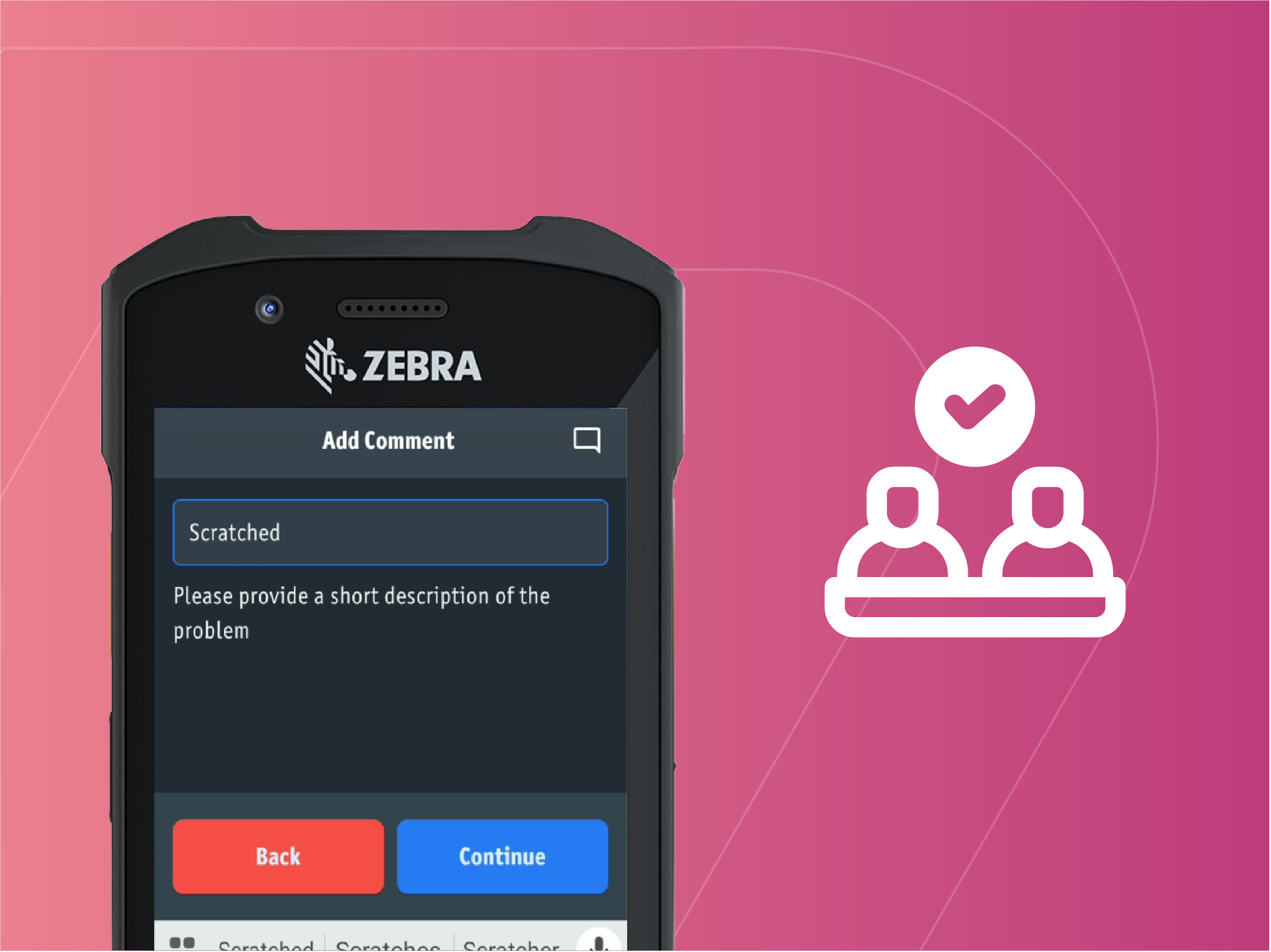

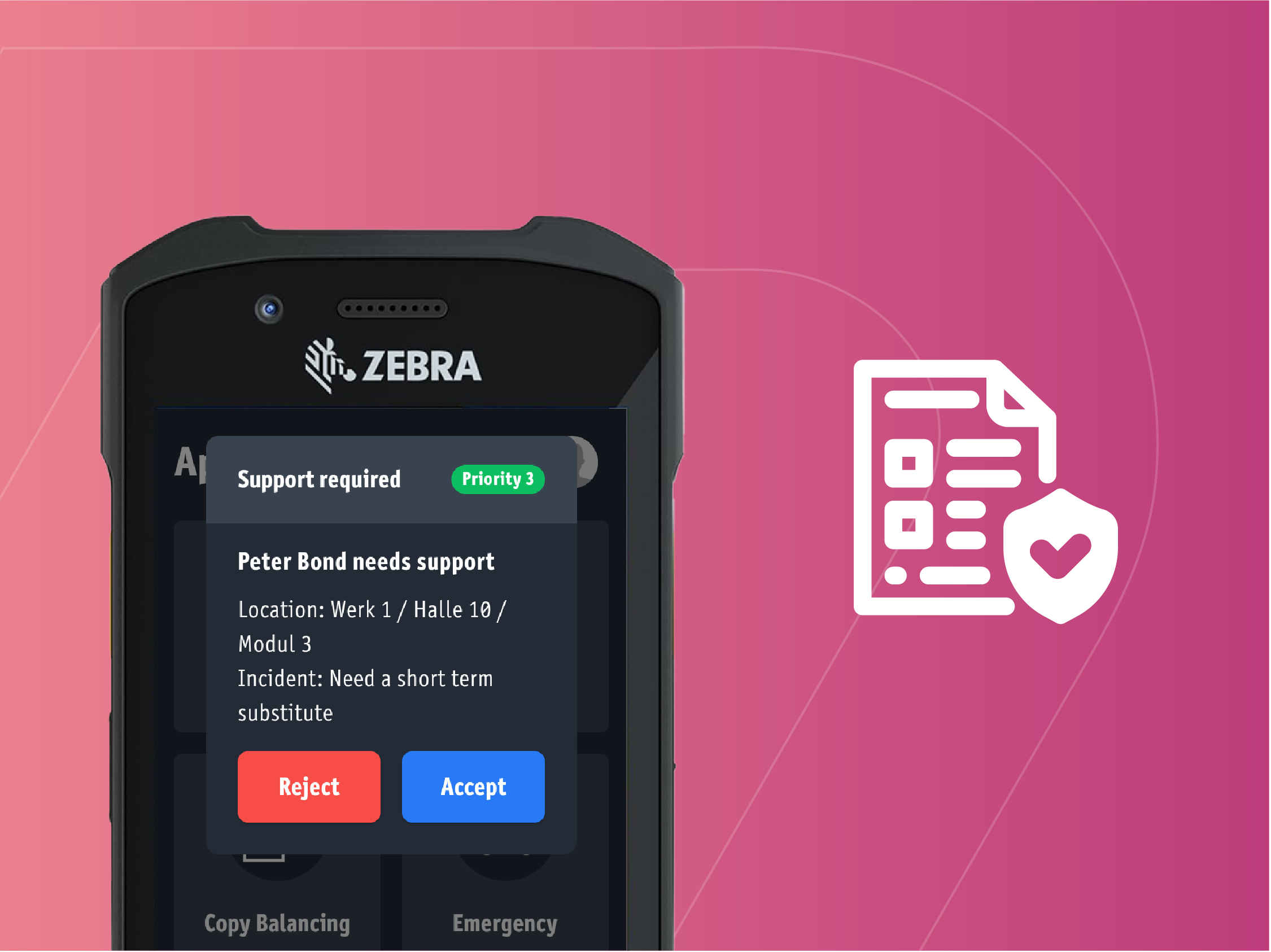

Workerbase allows you to run a powerful multi-step quality control process for your electronics production. Non conformances can be easily recorded by using the mobile app or from integration with (automated) optical inspection systems.

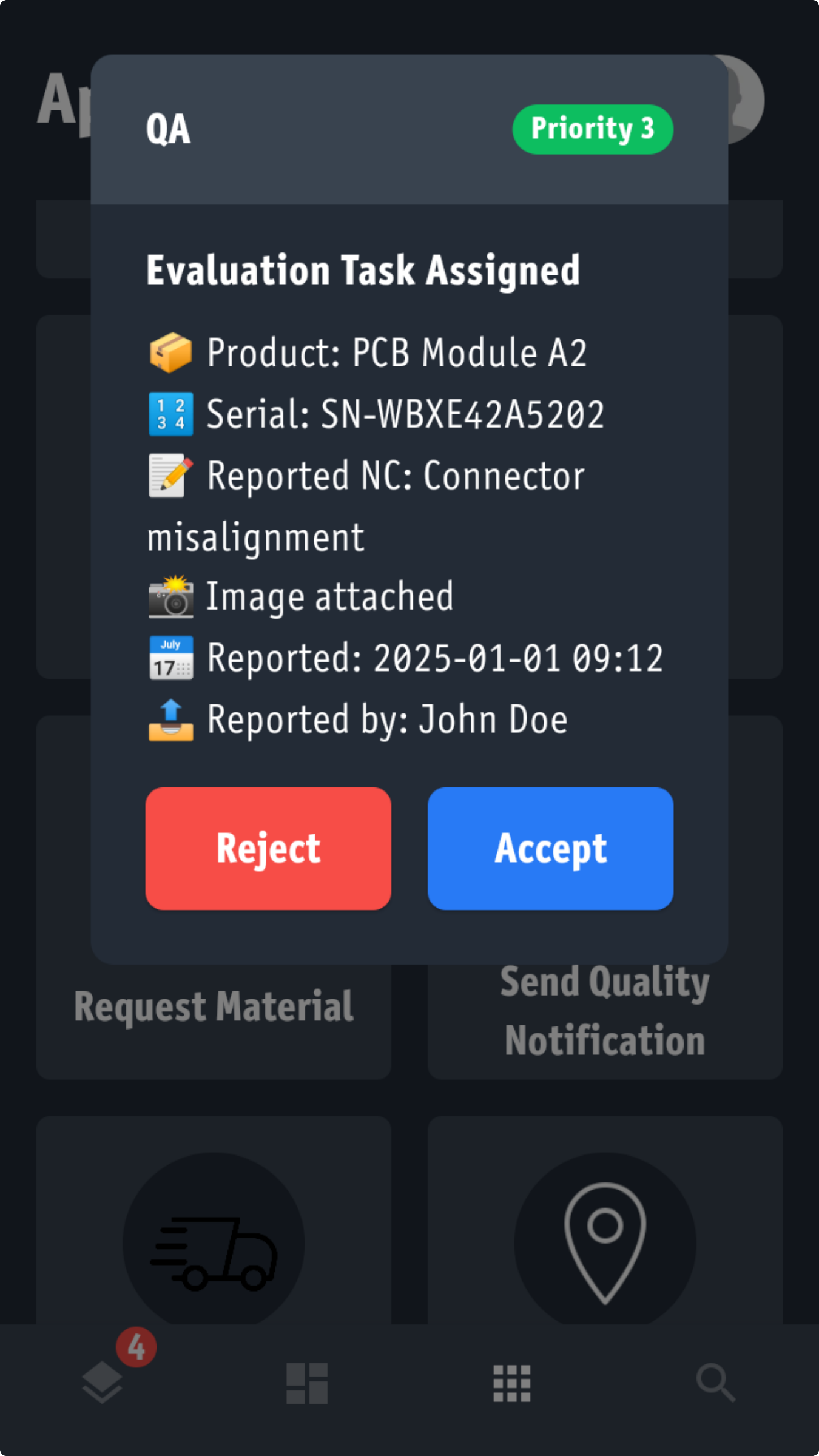

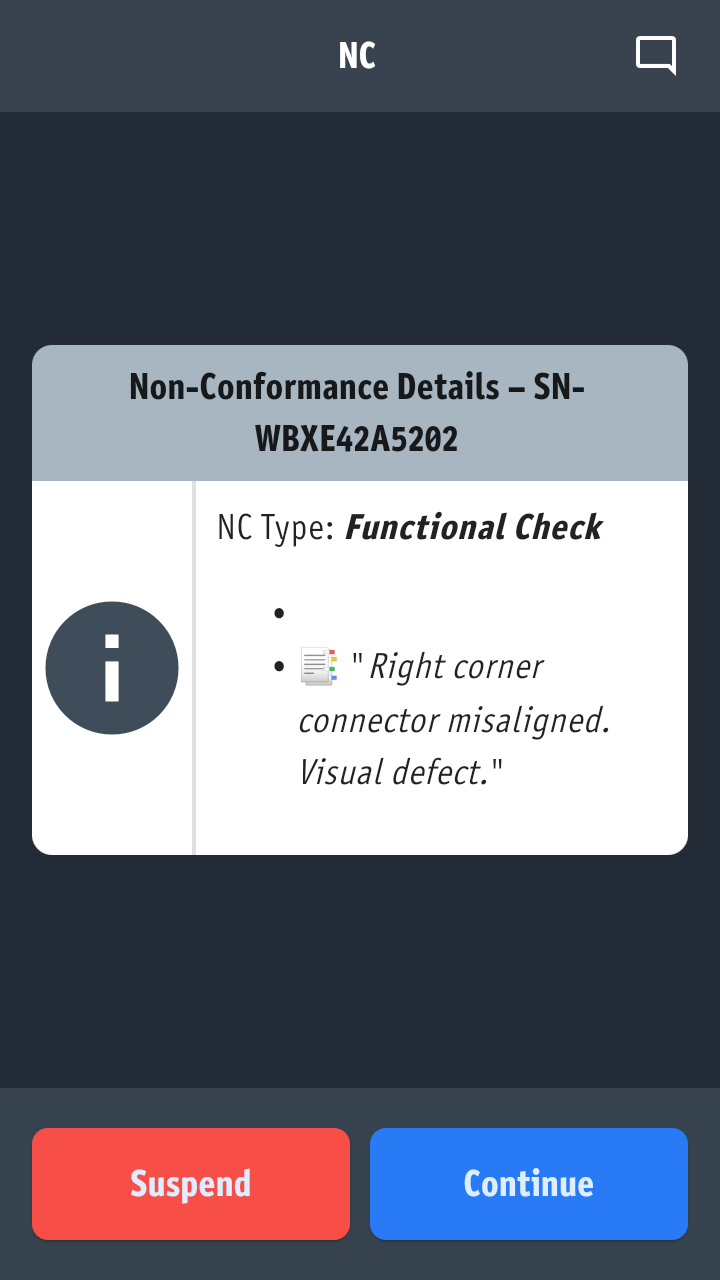

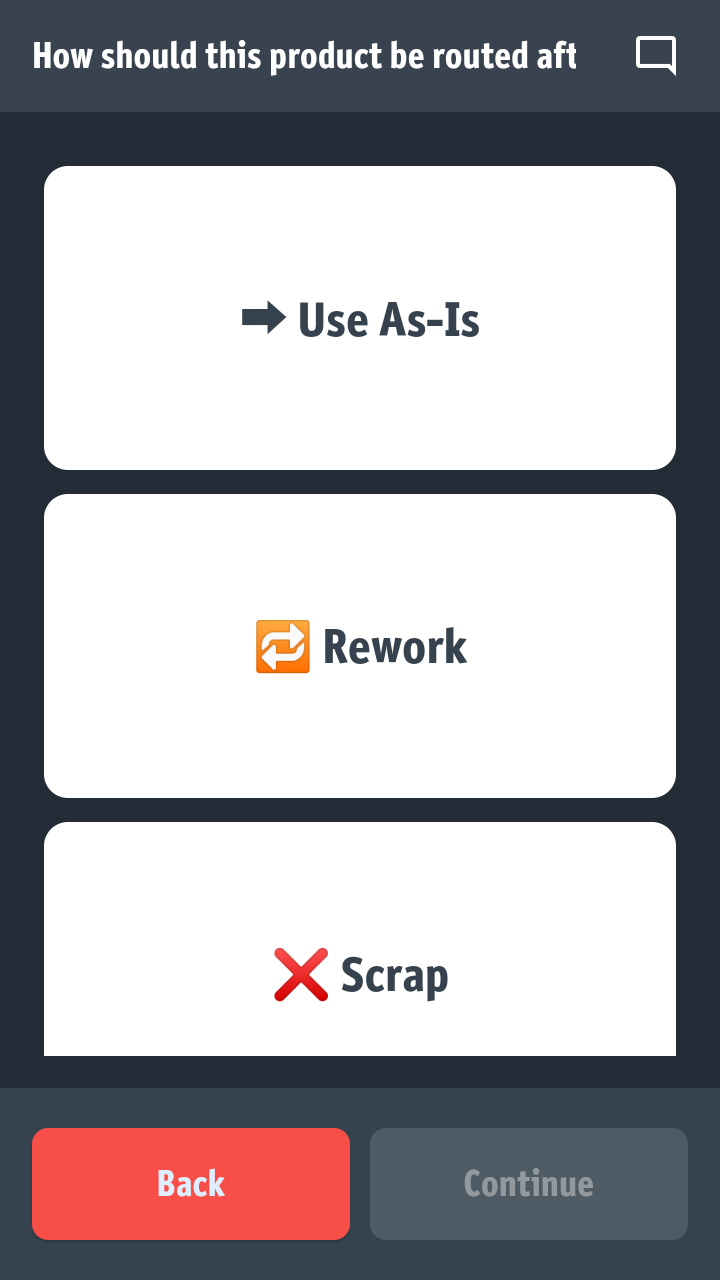

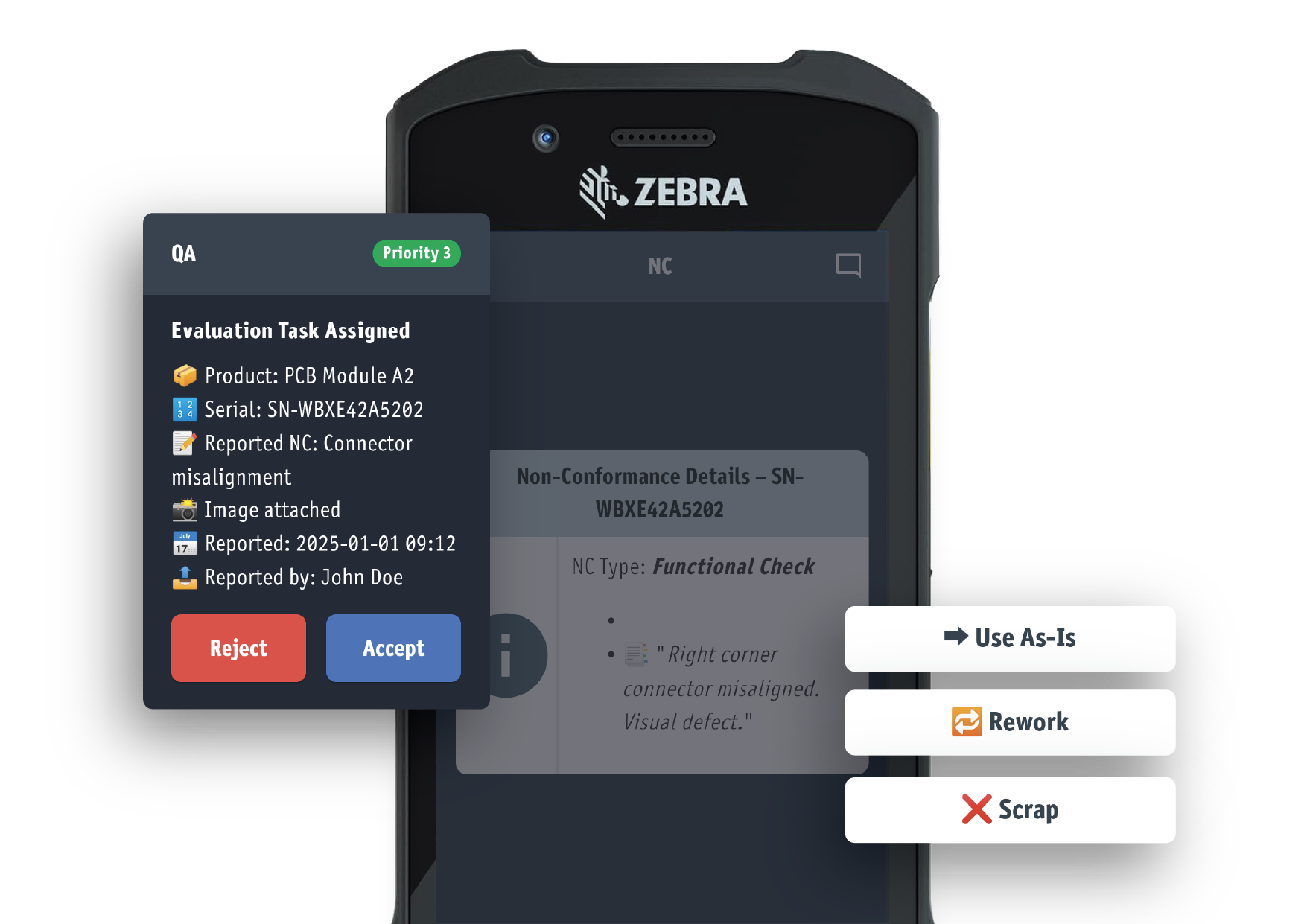

All incidents are forwarded to a quality manager to review and (re-)classify issues. If rework is required, digital instructions and tasks lists are provided at the rework stations. All data is traced for running root cause analysis.

All incidents are forwarded to a quality manager to review and (re-)classify issues. If rework is required, digital instructions and tasks lists are provided at the rework stations. All data is traced for running root cause analysis.

Streamlined Quality Processes for Maximum Yield and Faster Ship-Out

Higher Yields

Comprehensive quality process to reach highest yield rates

Fewer Errors

Easy root cause analysis using a unified documentation format

Faster Delivery

Faster ship-out using automated process coordination

A digital quality control process ensures higher yield rates

Existing Processes

- Quality deviations are recorded in isolated systems or on paper

- Difficult to track down root causes with information provided on paper and in different format and granularity

- Delays due to unclear handling processes of defect items

With Workerbase

- Integration with optical inspection systems ensures fast process flow and complete traceability

- AI assisted defect registration process ensures all deviations are recorded in the same and complete format

- Automated process control ensures all experts get involved at the right moment of the process

Discover Why Industry Leaders Use Workerbase

We’d love to walk you through how our platform can solve your specific manufacturing and production challenges and deliver measurable results.

We’d also be happy to share more insights on how our platform tackles challenges such as:

- Information access and task related support for frontline workers

- Inflexible and siloed IT infrastructure, such as existing MES or ERPs

- Achieving data maturity from your entire manufacturing ecosystem