Digital Checklists: Precision and Compliance in Manufacturing

Transforming Traditional Checklists for Enhanced Manufacturing Precision

Checklists have long been essential in manufacturing for ensuring adherence to processes. With the advent of Connected Worker platforms, the transformation of these checklists into digital formats brings a plethora of benefits, elevating precision, and efficiency, and contributing significantly to operational excellence.

Digital Checklists: The Evolution from Paper to Digital Efficiency

- Improving Process Adherence: Paperless checklists streamline and standardize operations, significantly reducing the likelihood of errors and ensuring consistent task execution.

- Real-Time Task Monitoring: Digital checklists enable the tracking of tasks in real-time, offering instant updates on progress and completion.

- Customization and Adaptability: Unlike static paper checklists, digital versions can be customized to specific processes, making them highly adaptable to changing requirements.

- Efficient Data Collection: These checklists simplify data gathering, allowing for an in-depth analysis of operational performance and compliance.

Case Study in Quality Control

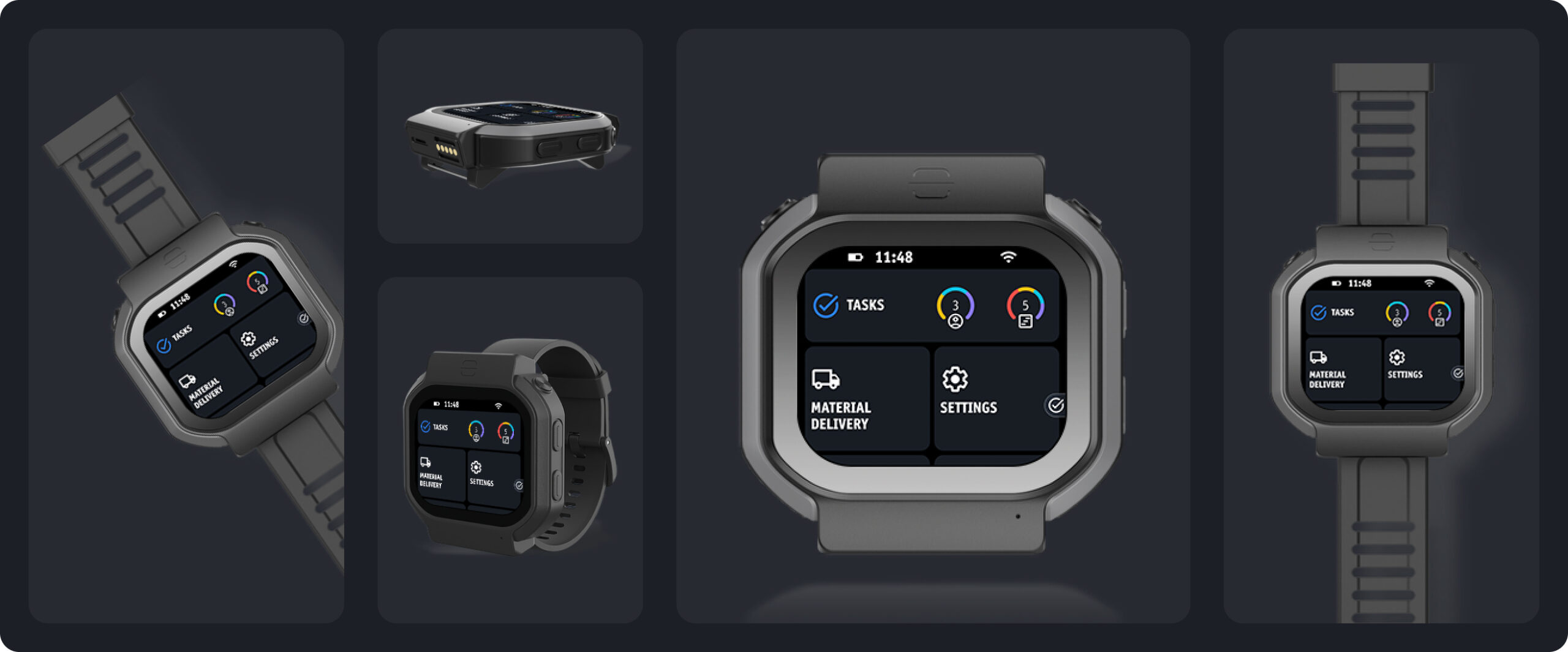

Consider a scenario in quality control within manufacturing. Using Connected Worker solutions, digital checklists become a critical tool. Employees access detailed checklists on mobile devices, ensuring each quality criterion is thoroughly checked and updated in real-time, thereby enhancing the overall quality assurance process.

Enhancing Digital Checklists with Connected Worker Features

- Customizable Templates: Tailor checklist templates to fit specific processes and evolving needs.

- Real-Time Updates: Ensure checklists are continually updated, providing immediate task completion visibility.

- Multimedia Integration: Include images or videos in checklists for clearer instructions and easier comprehension.

- Offline Accessibility: Allow checklist completion in areas with limited network connectivity.

- Automated Follow-Up Actions: Convert data inputs into automated workflows for efficient task coordination.

- AI Integration: Utilize AI to create, assess, and improve checklists continuously.

Transitioning from Paper to Digital Checklists: A Strategic Approach

- Identify Key Checkpoints: Start by pinpointing critical checkpoints in your processes where digital checklists can enhance quality and adherence.

- Design Comprehensive Checklists: Create clear, concise checklists that align with your organizational objectives.

- Seamless Workflow Integration: Ensure the Connected Worker platform integrates effortlessly with your existing systems.

- Focus on Employee Training: Emphasize the importance of digital checklists and provide comprehensive training to your team.

- Commit to Continuous Improvement: Regularly update your checklists based on feedback and evolving requirements, promoting a culture of continuous improvement.

By adopting these strategies, manufacturing facilities can leverage Connected Worker Solutions, Digital Work Instructions, and Electronic Work Instructions to achieve a higher standard of quality and efficiency.

This was just a teaser of what we have to show you. To learn everything about Connected Worker – read our in-depth white paper: