If you want to improve the effectiveness of your 5S audits and eliminate the hassle of paper checklists, this guide shows you exactly how to create a digital 5S checklist using Workerbase.

A 5S audit is only as strong as the process behind it. With Workerbase, you can digitize your 5S audit workflow—making it faster, easier, and more impactful across teams and shifts.

Looking for a primer on what 5S is and why it matters in lean manufacturing? Read our blog post on the fundamentals of 5S.

Benefits of a digital 5S checklist

Paper-based audits often result in:

- Incomplete or missing data

- Difficult-to-track corrective actions

- Manual effort to analyze trends or compare locations

With a digital 5S checklist in Workerbase, you get:

- Structured, high-quality audit data

- Immediate task creation for follow-ups

- Mobile access on the shop floor

- Photo documentation and timestamped entries

- Centralized records and KPI tracking

Step-by-step: Creating a digital 5S audit checklist in Workerbase

You can configure and launch your digital 5S checklist in minutes. Here’s how:

1. Define your audit structure

Start by outlining your audit format. Most 5S checklists follow the five common pillars:

- Sort – Eliminate clutter and unused items

- Set in order – Organize tools, parts, and documents

- Shine – Maintain cleanliness in the area

- Standardize – Apply consistent labeling and processes

- Sustain – Reinforce and audit the practices regularly

Each of these pillars becomes a section in your checklist.

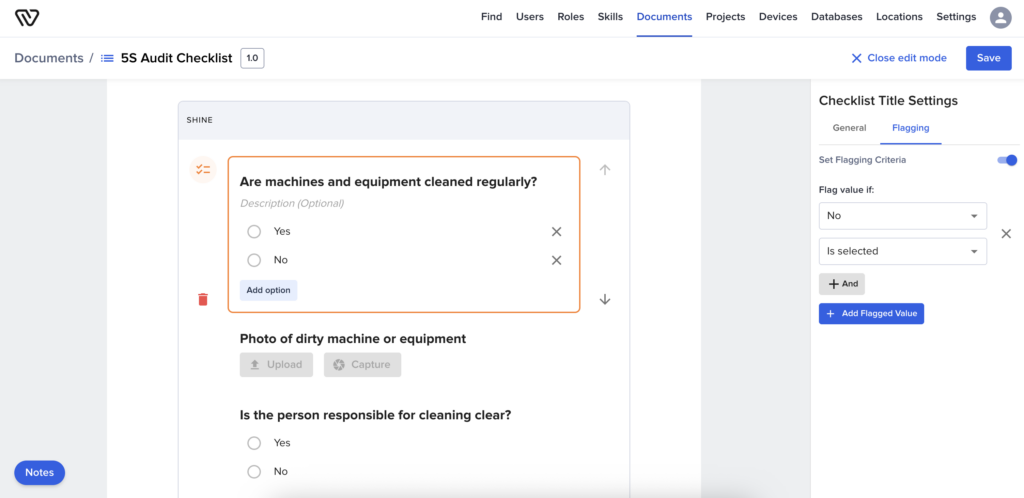

2. Create your digital form using Workerbase checklists

Workerbase’s forms and checklists feature is built for shop floor simplicity. You can simply create a form and add the fields you need. Additionally, you can choose from flexible input types such as:

- Text fields – for open-ended responses

- Dropdowns or multiple choice – for standardized scoring or issue categorization

- Yes/No toggles – ideal for binary checks

- Photo capture – attach visual evidence of area conditions

Grouping these fields under each 5S pillar, allowing teams to work through the audit in a structured, intuitive way.

Furthermore, Workerbase forms are optimized for mobile devices such as tablets and smartphones, so operators can use them directly on the shop floor.

3. Schedule or trigger the 5S audit

You decide how the checklist should be used:

- Scheduled audits: Daily, weekly, or monthly tasks auto-assigned to roles or teams

- Event-triggered: Initiated when a shift starts or a downtime event occurs

- Ad-hoc: Manually started for example by supervisors or QA managers

This flexibility ensures audits happen consistently without needing reminders or paper logs.

4. Assign follow-up tasks and ensure accountability

If an auditor identifies an issue—say, a dirty workbench or unlabeled part storage—they can log it immediately. Workerbase supports:

- Instant follow-up task creation

- Escalation paths based on severity or area

- Photo and comment attachments for context

Each entry becomes trackable, ensuring no item is forgotten or closed prematurely.

5. Analyze audit results and spot trends

Every completed checklist feeds data into Workerbase’s backend. You can:

- Track compliance rates by team or station

- Analyze recurring problem areas by 5S category

- Generate reports for regulatory or customer audits

- Compare performance across shifts or locations

All of this without chasing down binders or spreadsheets.

Sample questions to use in your 5S audit checklist

Here are some exemplary questions you can use for your digital 5S checklist:

Sort

- Are unnecessary items removed from the area?

- Is outdated inventory clearly marked and removed?

Set in Order

- Are all tools stored in their designated locations?

- Are storage areas clearly labeled and accessible?

- Are all machines regularly wiped clean?

- Are markers used to indicate storage areas and walkways?

Shine

- Is the floor clean and free of spills or debris?

- Are machines and equipment cleaned regularly?

- Is the person responsible for cleaning clear?

Standardize

- Are visual controls (labels, color codes, etc.) consistent?

- Are standard operating procedures visible and actively used?

- Was a 5S audit completed for this area last month?

Sustain

- Are previous audit findings reviewed and addressed?

- Are team members aware of their 5S responsibilities?

- Are audit findings properly communicated to the team?

By digitizing these questions with text, yes/no, and photo input fields, you ensure clarity and accountability—without the ambiguity of handwriting or forgotten paper forms.