Modern Work Instructions, Enabled Through Connected Worker

Transforming Traditional Work Instructions

A critical advancement in Connected Worker platforms is the modernization of standard work instructions. Traditionally, these instructions have been confined to paper or isolated digital systems. Now, they are evolving into a dynamic, interactive, and real-time accessible format through digital work instruction technology.

Enhancing Productivity and Quality with Digital Work Instructions

This shift from static to dynamic, digital work instructions offers numerous benefits. Key among these is the significant boost in productivity and the reduction of errors on the shop floor. Workers gain access to the most current, step-by-step instructions, enabling more efficient task completion, minimized downtime, and enhanced production processes. Unlike paper manuals or PDFs, digital formats can be updated quickly, ensuring that workers always have the latest information, thereby improving output quality.

Case Study: Improving Assembly Line Efficiency

Imagine an assembly line where efficiency is paramount. Here, Connected Worker solutions play a vital role by providing workers with immediate access to digital work instructions, complete with visual aids and multimedia elements. The result is a more efficient assembly process, fewer errors, and the ability to swiftly adapt to production changes, leading to higher-quality end products.

Key Features of Digital Work Instructions

When selecting Connected Worker Solutions for optimizing work instructions, consider these essential features:

- User-friendly interfaces for easy comprehension.

- Multimedia integration for enhanced visual guidance.

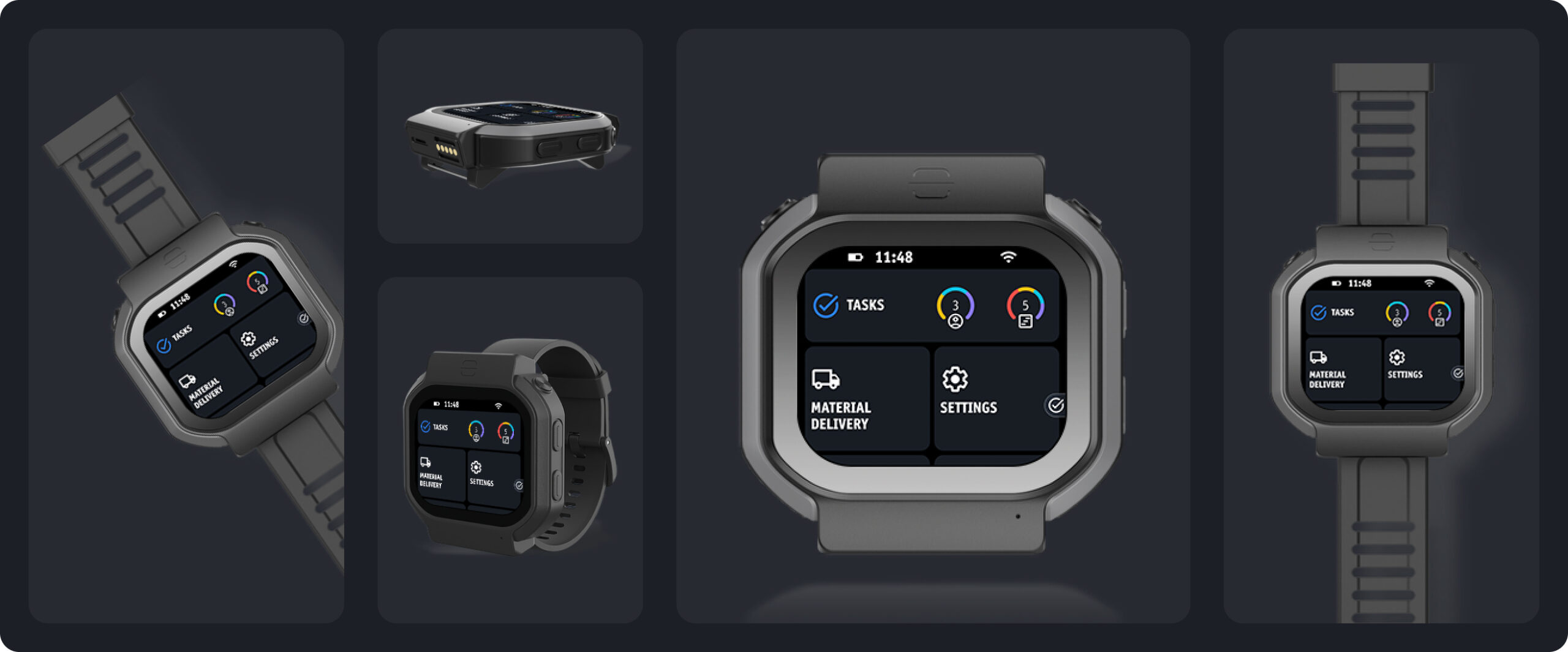

- Compatibility with various smart devices.

- Feedback loops for continuous instruction improvement.

- Automated follow-up workflows based on data input.

- Integration with AI systems for a blend of human and artificial intelligence.

- Customizable templates that fit various manufacturing processes.

Strategic Steps Toward Implementing Digital Work Instructions

- Process Mapping: Start by mapping current processes to identify where digital work instructions can be most beneficial. Look for bottlenecks or frequent changes in operations.

- Compatibility Assessment: Ensure the new digital system is compatible with existing systems for a smooth transition.

- Technical Roadmap Development: Create a detailed implementation plan, considering data security, user access, and scalability.

- Digital Transformation Integration: Align the digitalization of work instructions with the organization’s broader digital transformation strategy.

- Fostering User Adoption: The success of implementation relies on user adoption. Engage end-users from the beginning and offer training and incentives to build a digital-first culture among the workforce.

This was just a teaser, of what we have to show you. To learn everything about Connected Worker – read our in-depth white paper: