Lean manufacturing in the digital age

Traditional lean manufacturing practices are often reliant paper forms and manual processes that slow everything down. Digital lean processes eliminate these bottlenecks, making continuous improvement faster and easier to scale.

Lean manufacturing focuses on reducing waste and delivering more value to customers. It targets eight common types of waste—like overproduction, delays, extra movement, and unused employee skills.

Tools such as 5S, value stream mapping, Kanban, Kaizen and Gemba help tackle these issues, but paper-based implementation limits how well these tools can scale and sustain over time.

Digital lean manufacturing transforms proven methods into smart, connected processes.

- 5S audits track corrective actions automatically.

- Kanban systems trigger replenishment instantly.

- Kaizen improvements get implemented faster with better measurement.

- Value stream mapping becomes dynamic and real-time rather than static snapshots

Digital tools don’t change lean principles. They make them work better by removing manual bottlenecks and providing real-time data for smarter decisions.

Why choose Workerbase for lean manufacturing?

Core lean concepts enhanced by digital systems

Standardized work and continuous improvement

- Static standard work instructions become outdated quickly and don’t adapt to different skill levels.

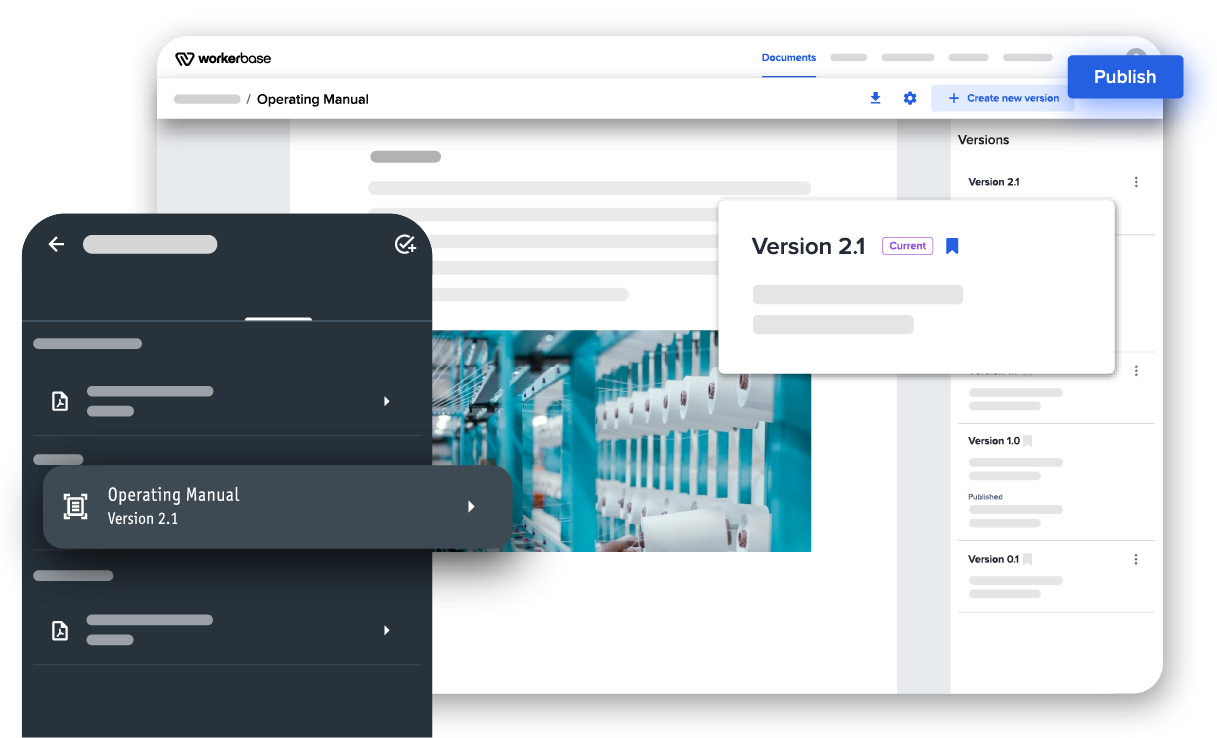

- Digital work instructions adjust automatically, providing detailed guidance for new operators and streamlined interfaces for experienced workers.

- They help ensure tasks are executed First Time Right, reducing defects and rework.

Problem solving and root cause analysis

- Traditional problem-solving happens after production is already affected.

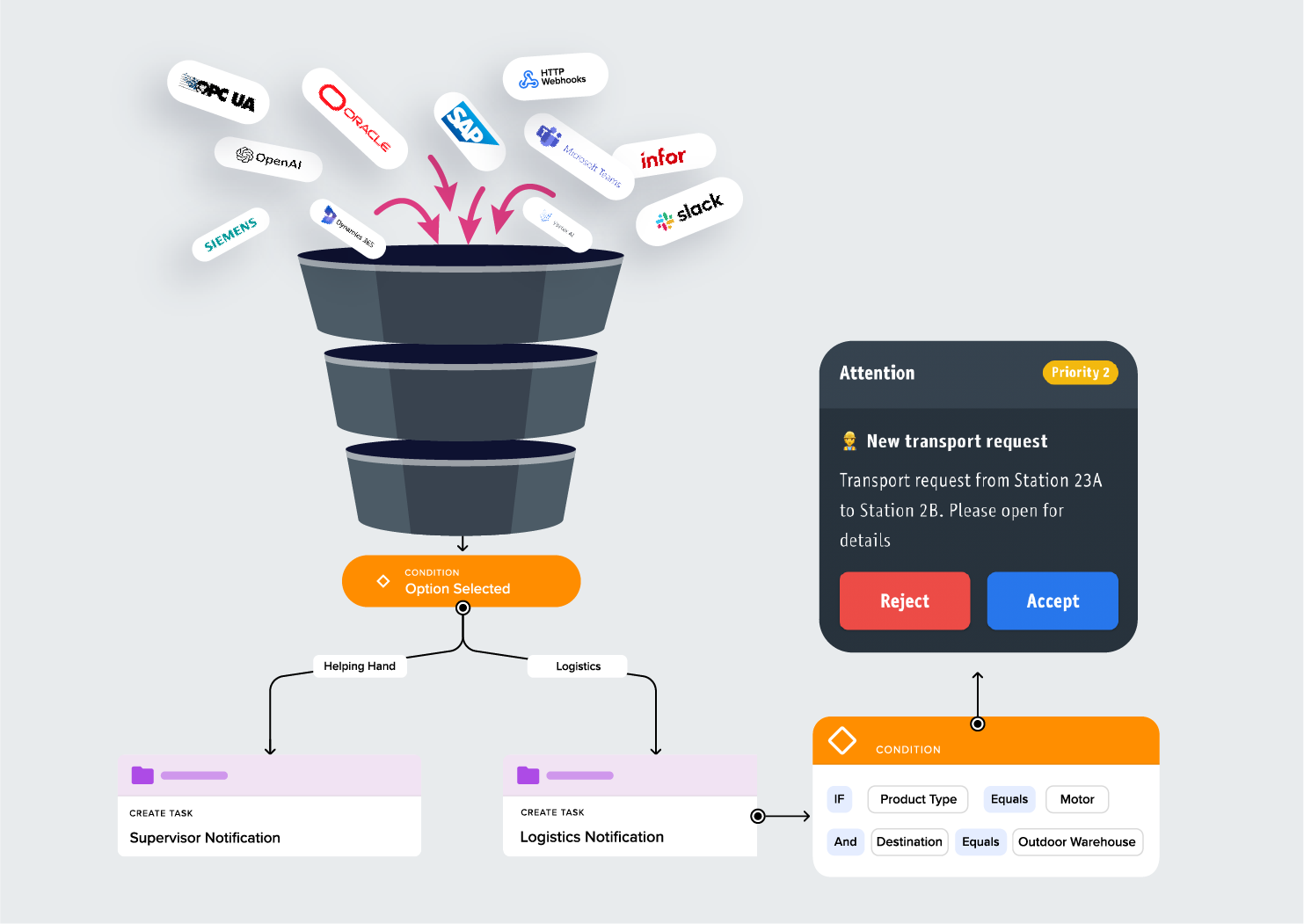

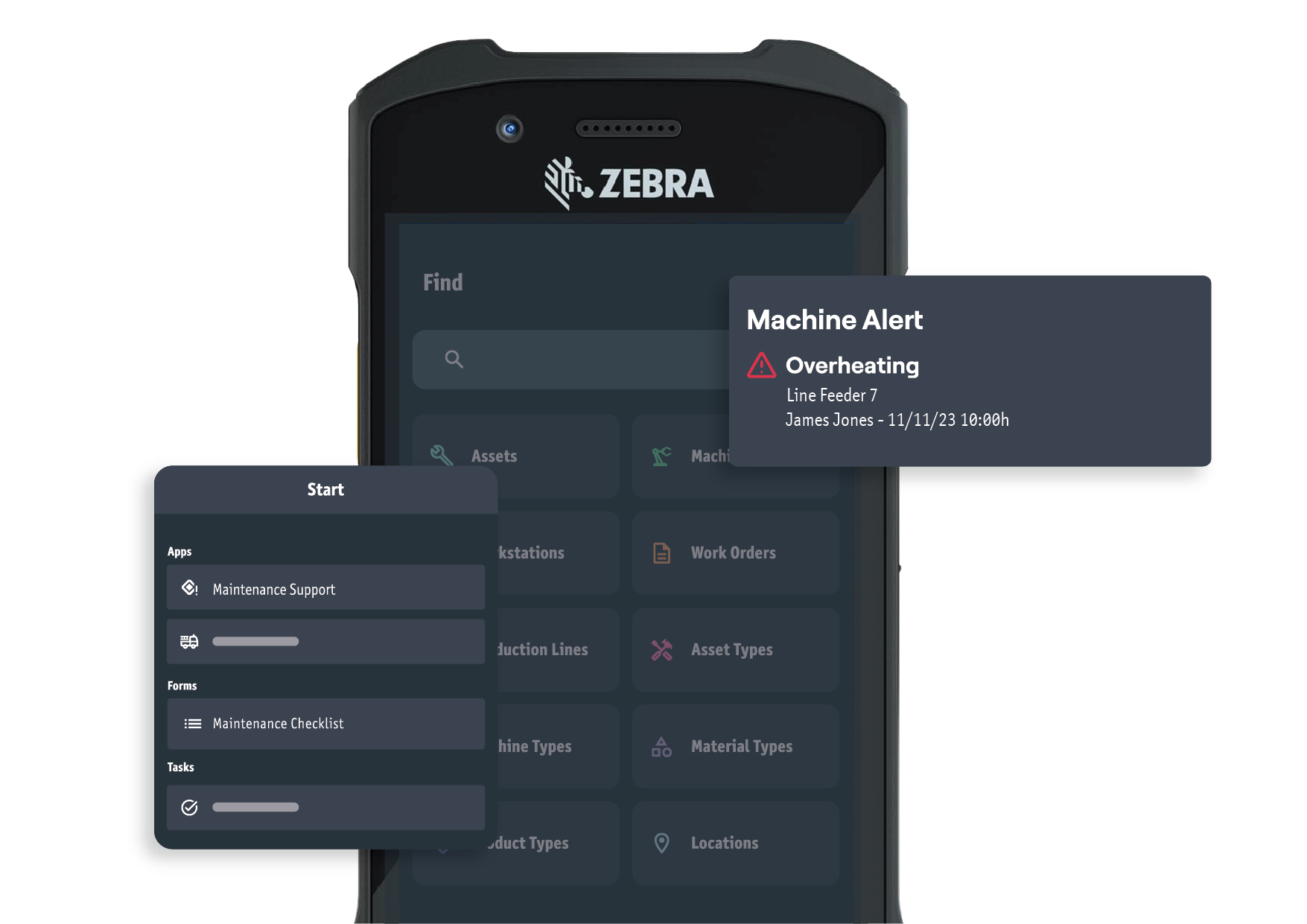

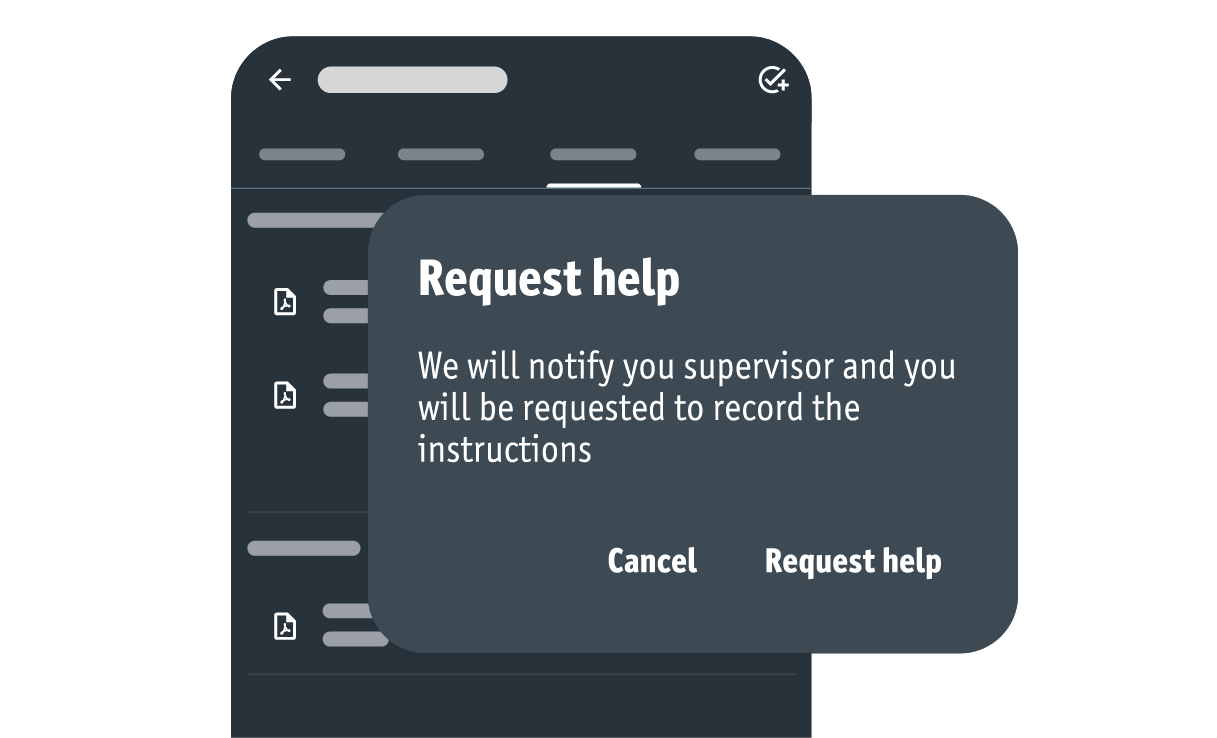

- Digital Andon systems detect problems immediately and route them to the people for fast response.

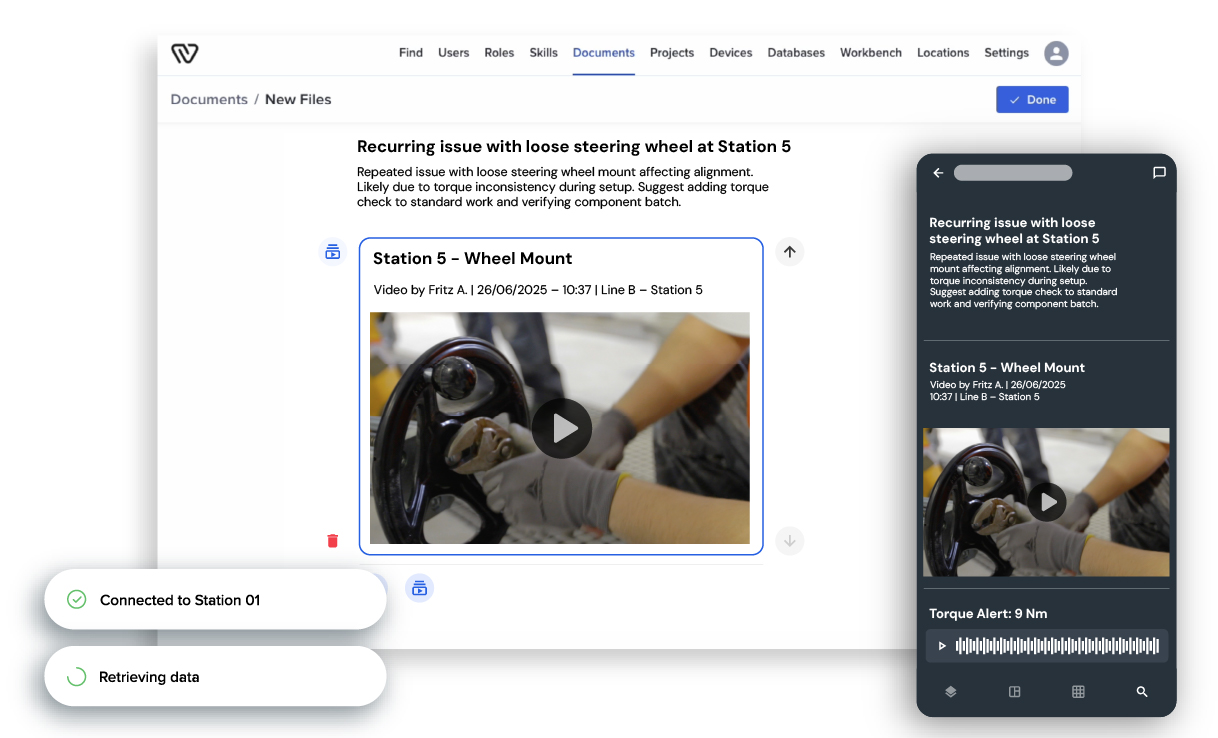

- They guide structured problem-solving, capture solutions, and build knowledge databases that preserve expertise even when experienced workers leave.

Pull systems and kanban management

- Physical Kanban cards get lost and need constant manual management.

- Digital Kanban systems trigger replenishment automatically based on actual consumption, integrate with suppliers for automatic ordering, and provide complete visibility into material flow.

- They adjust to upcoming demand and optimize inventory levels without manual effort.

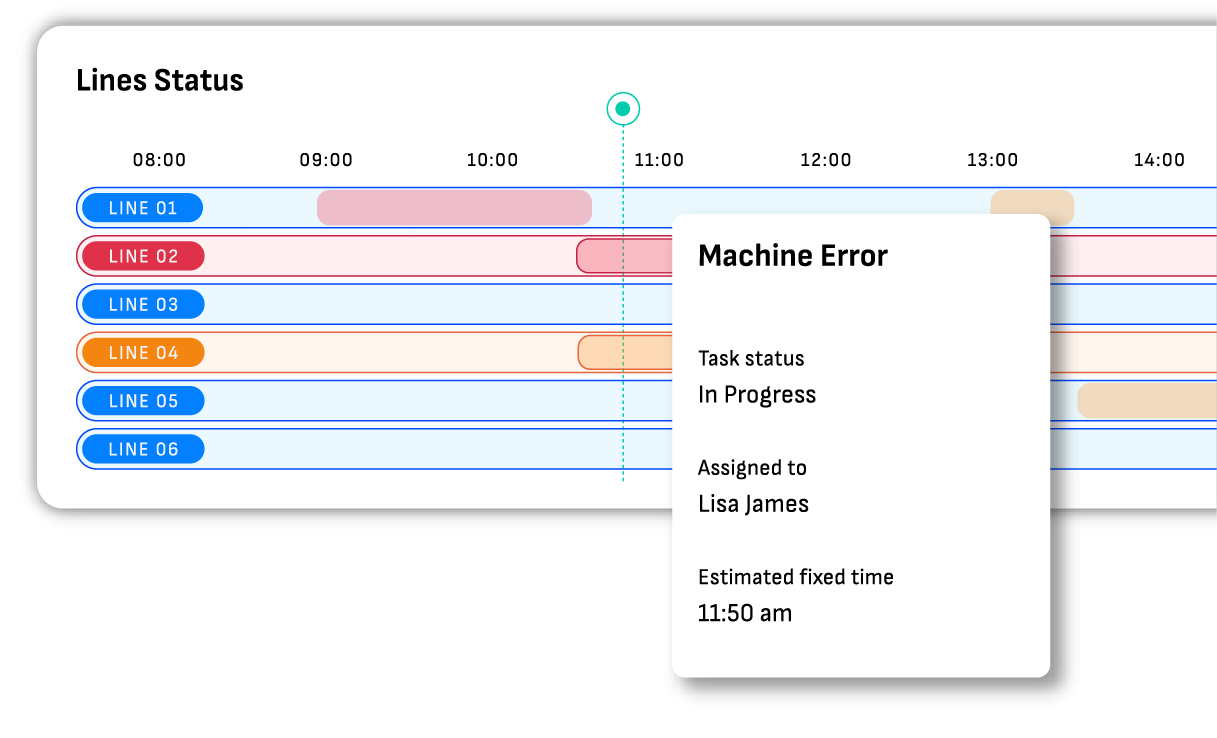

Value stream mapping and flow optimization

- Traditional value stream maps are snapshots that get outdated fast

- Digital mapping updates automatically with live production data, capturing cycle times and spotting bottlenecks in real-time without extra effort.

Powerful features designed to make your production leaner

Get a real-time overview of all your production data

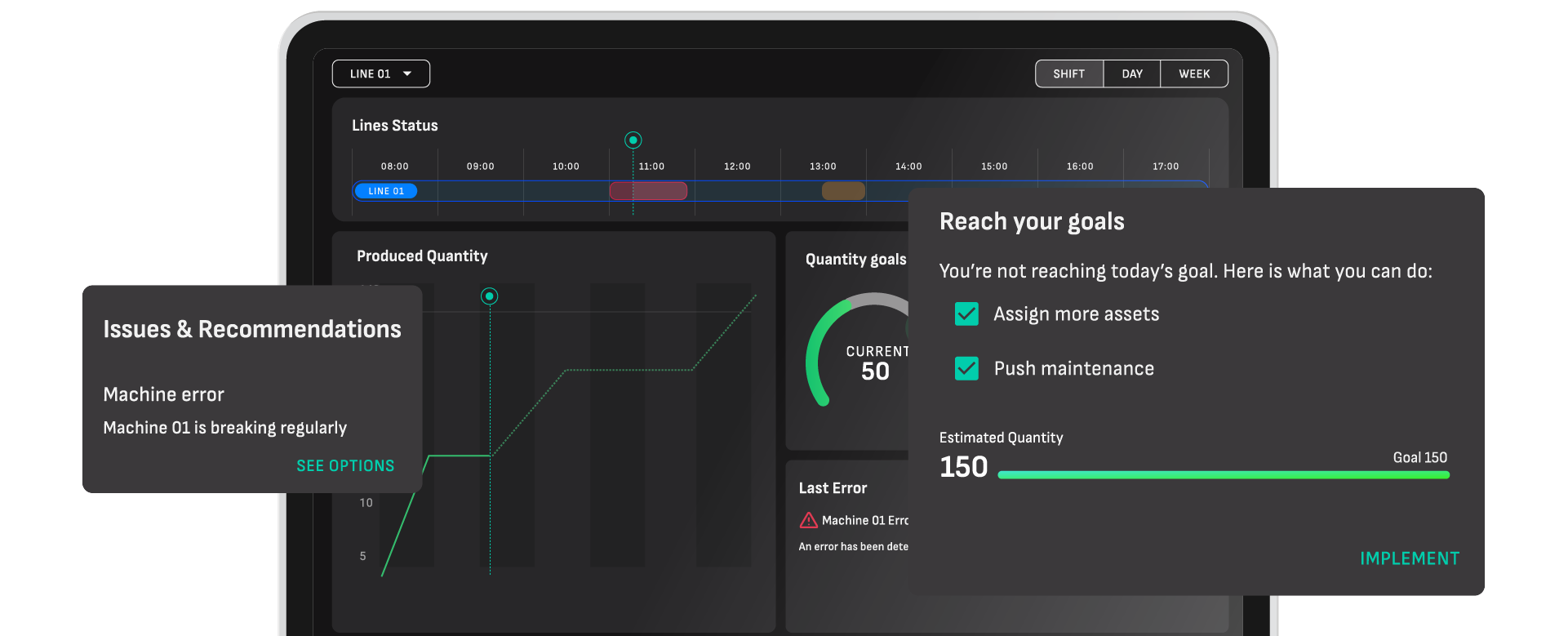

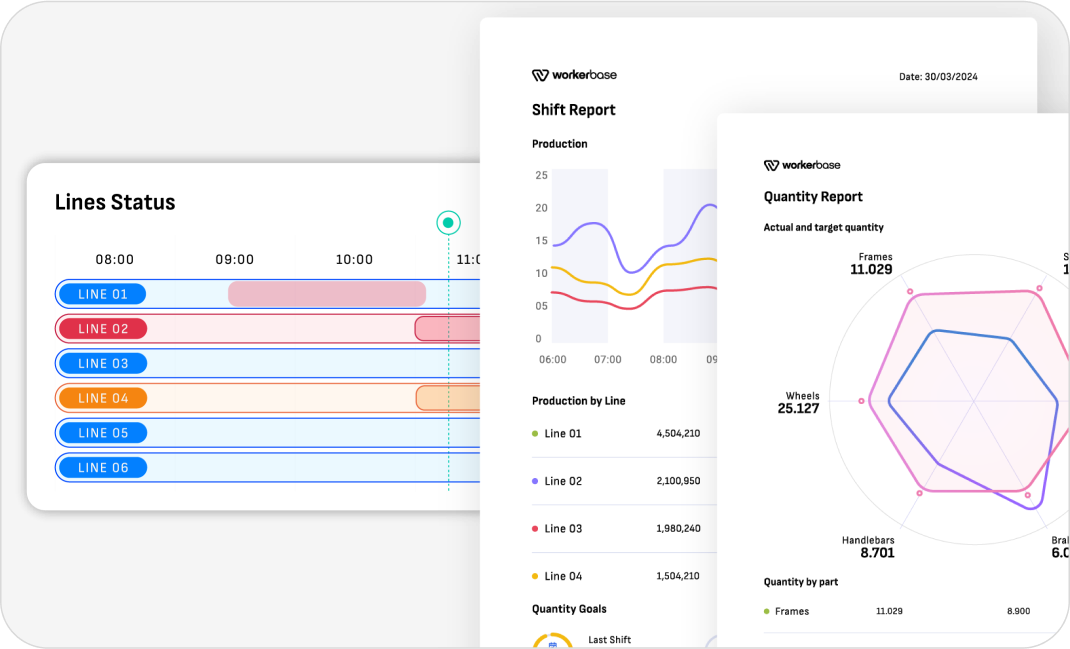

Make decisions with real-time data instead of week-old reports.

Real-time dashboards automatically combine data from all sources to show throughput, First Pass Yield (FPY), quality trends, and improvement progress instantly.

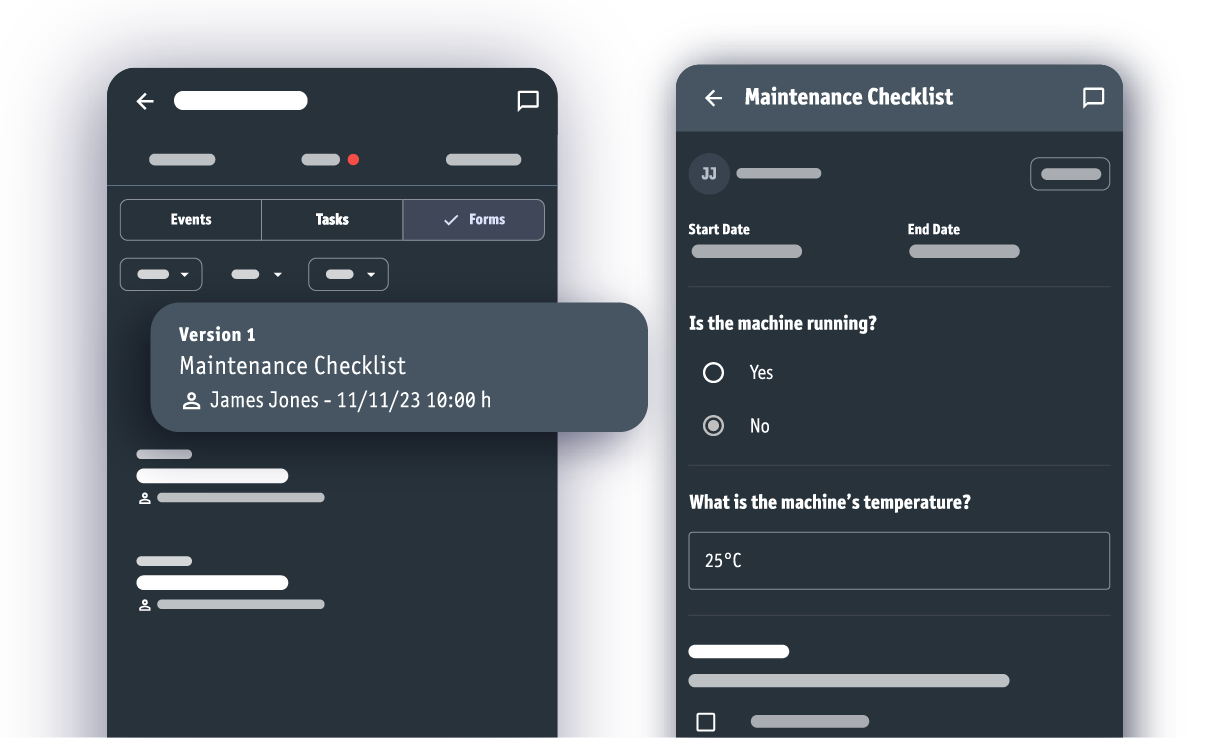

Easily embed lean practices into daily operations

Easily embed lean tasks and practices directly into your workers’ daily routines. Seamlessly foster a strong lean culture and drive consistent operational excellence.

Digital workflows make lean part of how work gets done, rather than additional activities—reinforcing behaviors like visual management and helping teams complete work First Time Right.

Easily address Who, What, Where, When and Why

See exactly what happens at every step to identify problems and maintain quality.

The system automatically records who did what, when, and where, giving you complete visibility for improvements and audits.

Turn shop-floor data into actionable insights

Collect data the same way every time and turn it into insights that show you exactly where to improve.

Stop guessing what’s wrong—let the data show you hidden problems and continuous improvement opportunities. Track metrics like rising scrap rates or rework frequencies, and uncover patterns that lead to unplanned downtime or slow throughput.

Implementation strategy for digital lean success

- Start by picking one lean process where digital improvements will be most obvious. Most organizations begin with 5S audits or problem-solving workflows in a pilot area where everyone can see the results.

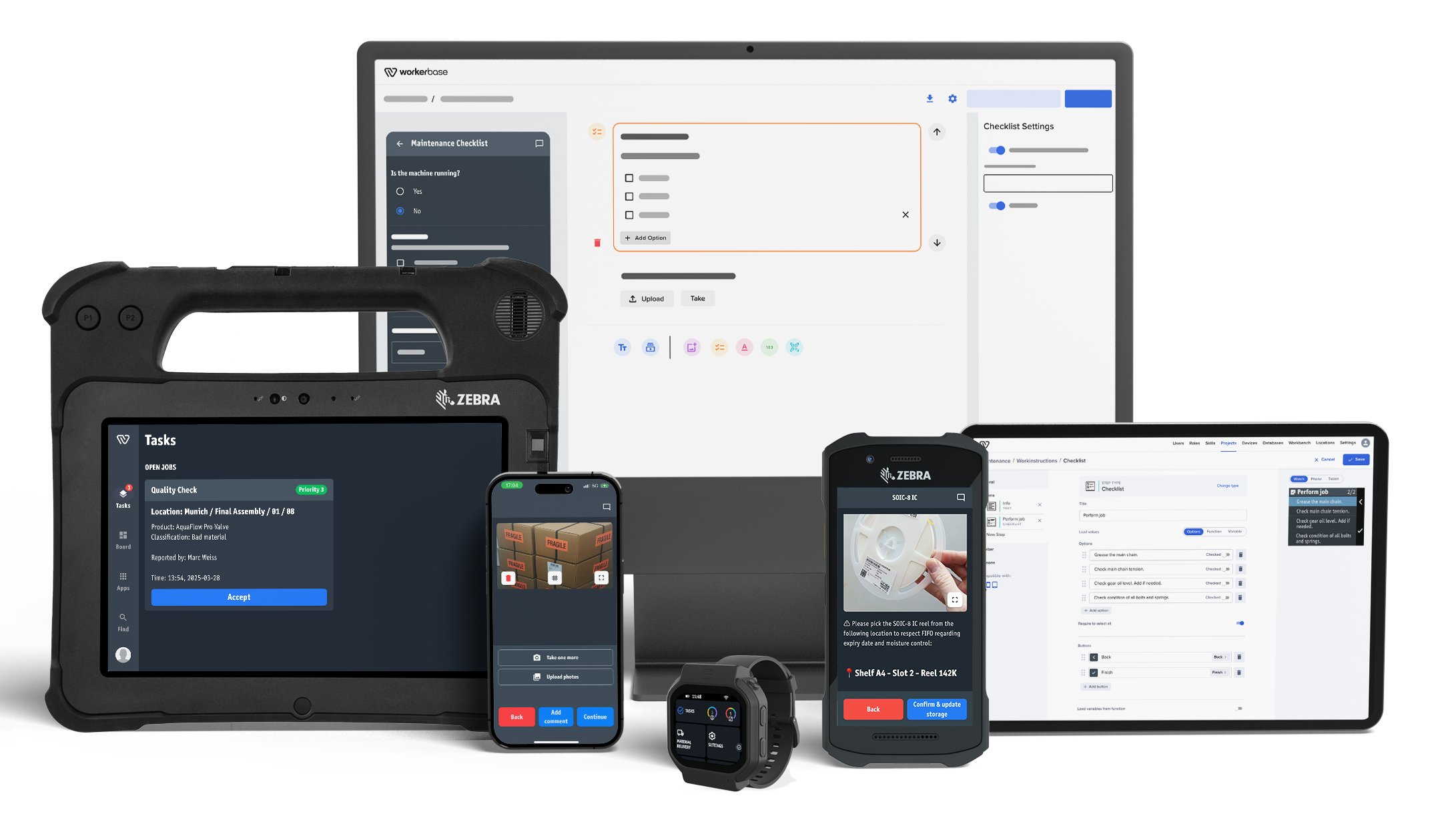

- Use Workerbase’s simple tools to build digital versions of your existing procedures, then test and improve them. This low-risk approach builds confidence before expanding to other areas and adding advanced features like automatic routing and system integration.

- The platform grows with your needs. Simple digital forms become advanced workflows with smart routing and automatic alerts. Basic data collection turns into real-time dashboards with trend analysis—capturing OEE, First Pass Yield, scrap rates, and downtime so you can continuously improve based on real-world feedback. Successful pilots expand across multiple sites while maintaining central control and local flexibility.

Ready to digitize your shop floor operations?

We’d love to walk you through how our platform can solve your specific manufacturing and production challenges and deliver measurable results.

We’d also be happy to share more insights on how our platform tackles challenges such as:

- Information access and task related support for frontline workers

- Inflexible and siloed IT infrastructure, such as existing MES or ERPs

- Achieving data maturity from your entire manufacturing ecosystem